Shaped permanent magnet and preparation method thereof, and equipment for preparing shaped permanent magnet

A permanent magnet, special-shaped technology, applied in the direction of magnets, magnetic objects, permanent magnets, etc., can solve the problems of large waste, low material yield, low preparation efficiency, etc., and achieve the effect of high efficiency and high material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of a special-shaped permanent magnet, which comprises the following steps:

[0036] S1, providing magnetic powder with magnetocrystalline anisotropy;

[0037] S2, performing hot pressing and heat deformation on the magnetic powder in sequence to obtain a heat deformed blank; and

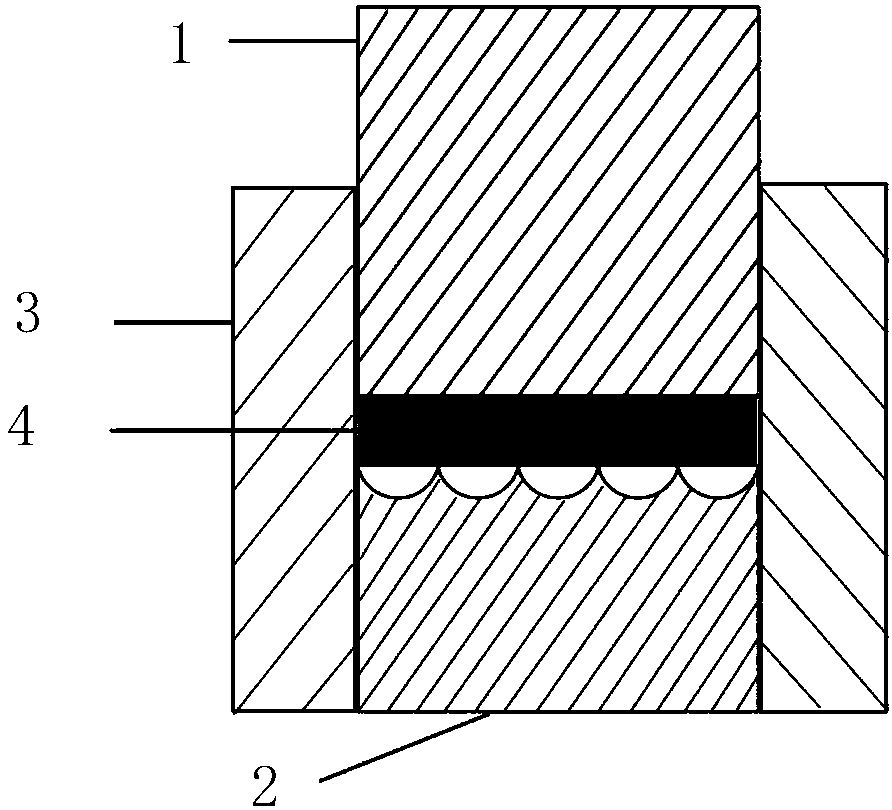

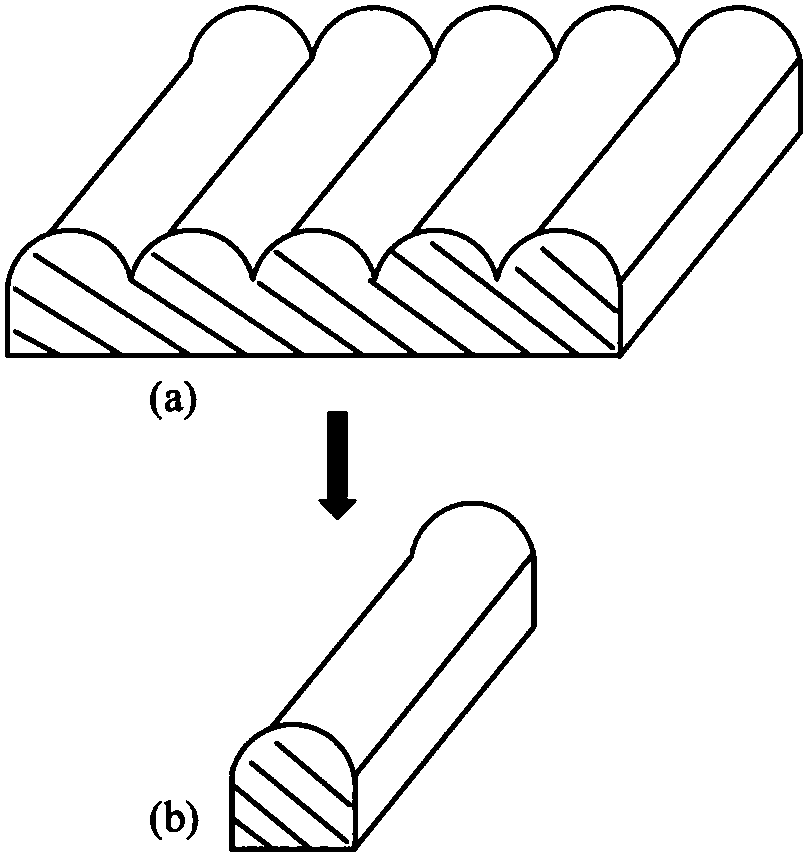

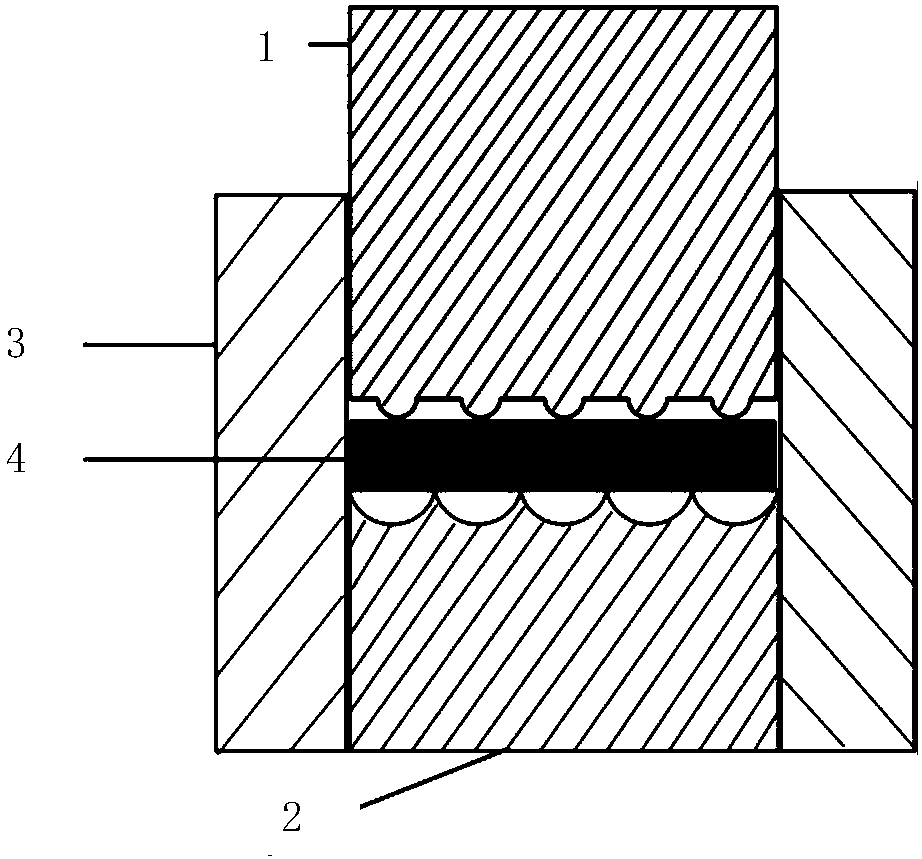

[0038] S3, providing a shaping mold, the end surface of the indenter of the shaping mold includes at least one arc surface, putting the heat-deformed blank into the shaping mold, and heating and applying pressure to the heat-deformed blank, so that the The heat-deformed blank undergoes rheology and fills the mold cavity of the shaping mold to obtain a special-shaped permanent magnet, wherein the surface of the special-shaped permanent magnet includes at least one arc surface.

[0039] In step S1, the magnetic powder is at least one of NdFeB magnetic powder, SmCo magnetic powder, and SmFeN magnetic powder. The magnetic powder can be purchased from t...

Embodiment (1

[0049] The preparation process of the single-arc special-shaped permanent magnet is as follows:

[0050] (1) Hot pressing: Sm with a particle size of 50-100 microns 2 co 17 Put the magnetic powder into the first mold, heat the magnetic powder to a first temperature in a vacuum environment, and apply a first pressure to the first mold to obtain a hot-pressed blank, wherein the first temperature is 700°C, and the first A pressure is 200MPa, and the vacuum degree of the vacuum environment is 3×10 -2 Pa.

[0051] (2) Thermal deformation: put the hot-pressed blank into the second mold, heat the hot-pressed blank to the second temperature in argon gas, and make the hot-pressed blank undergo deformation with a deformation amount of 80% , and then apply a second pressure to the deformed hot-press blank to obtain a hot-deformed blank 4, wherein the second temperature is 850° C., and the second pressure is 100 MPa.

[0052] (3) Shaping and shaping: put the thermally deformed blank 4...

Embodiment (2

[0057] The preparation process of double-arc shaped permanent magnets with different radii of inner and outer arcs is as follows:

[0058] (1) Hot pressing: Nd with a particle size of 50-350 microns 2 Fe 14 B The magnetic powder is put into the first mold, the magnetic powder is heated to the first temperature in a vacuum environment, and the first pressure is applied to the first mold to obtain a hot-pressed blank, wherein the first temperature is 680°C, the The first pressure is 150MPa, and the vacuum degree of the vacuum environment is 5×10 -2 Pa.

[0059] (2) Thermal deformation: put the hot-pressed blank into the second mold, heat the hot-pressed blank to the second temperature in argon, and make the hot-pressed blank undergo deformation with a deformation amount of 70%. , and then apply a second pressure to the deformed hot-press blank to obtain a hot-deformed blank 4, wherein the second temperature is 830° C., and the second pressure is 70 MPa.

[0060] (3) Shaping ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap