Battery core assembly jig and battery core assembly method

A cell assembly and fixture technology, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of frequent actions, complicated fixing methods, cumbersome assembly, etc., and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better explain the present invention and facilitate understanding, the following describes the present invention in detail through specific embodiments in conjunction with the accompanying drawings.

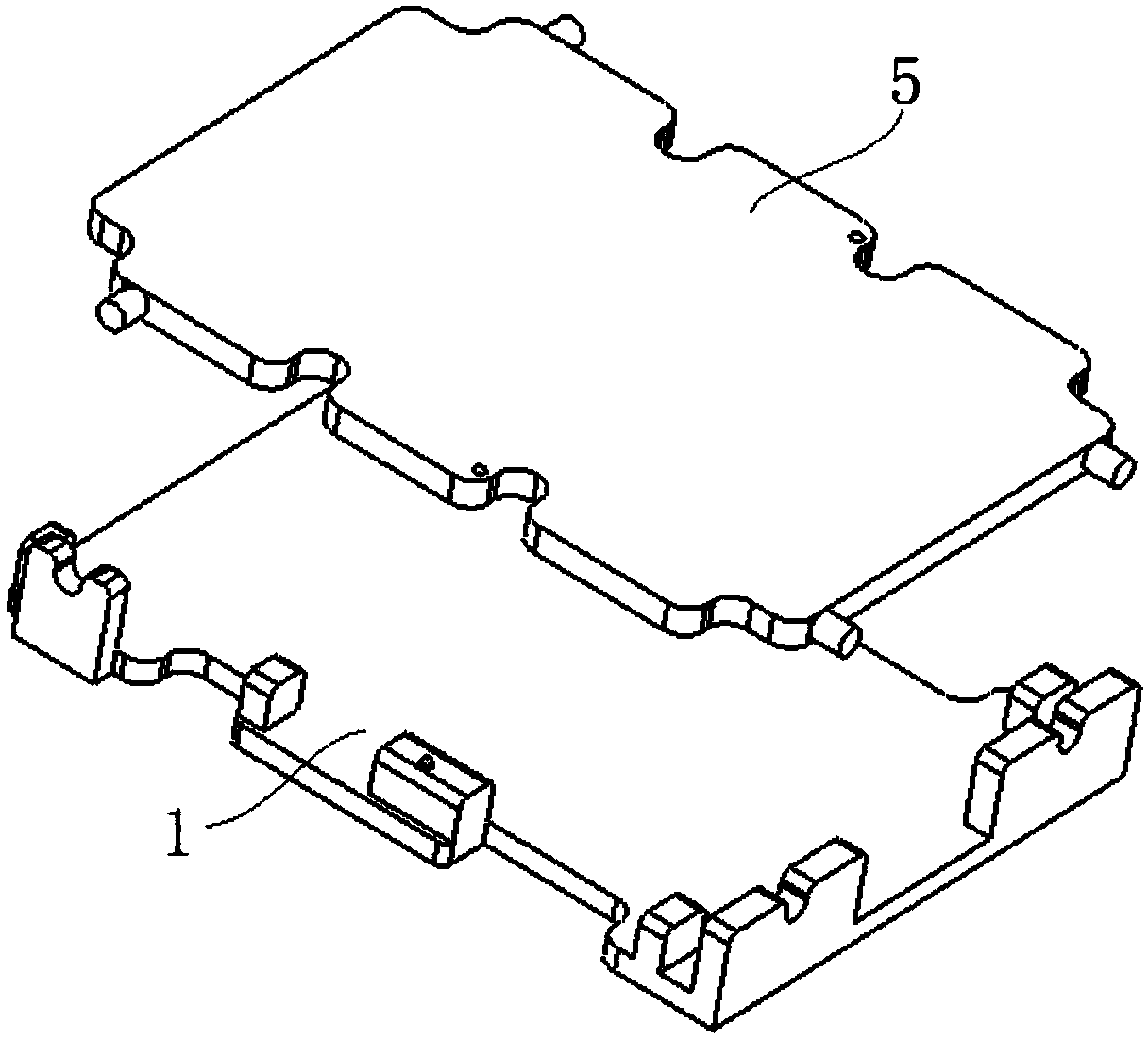

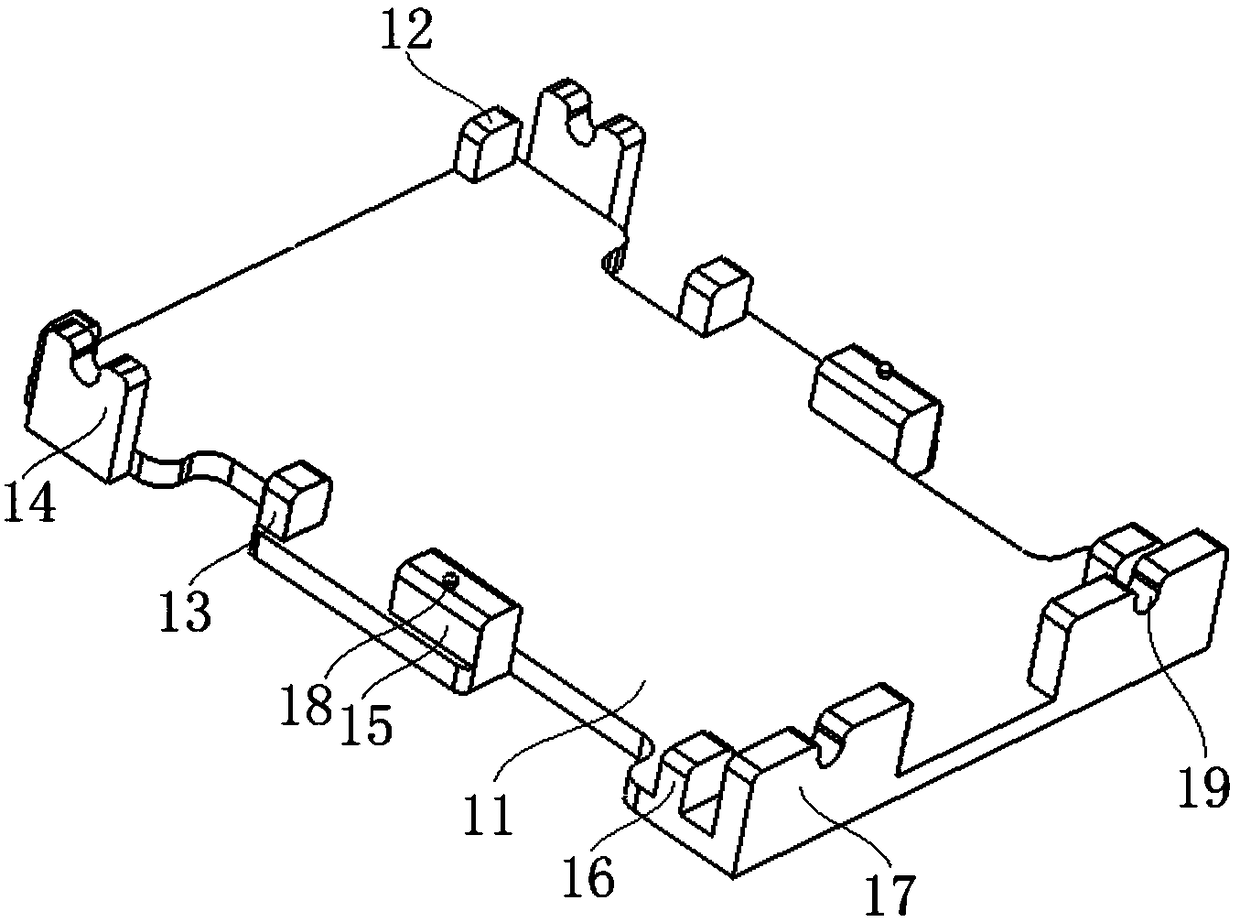

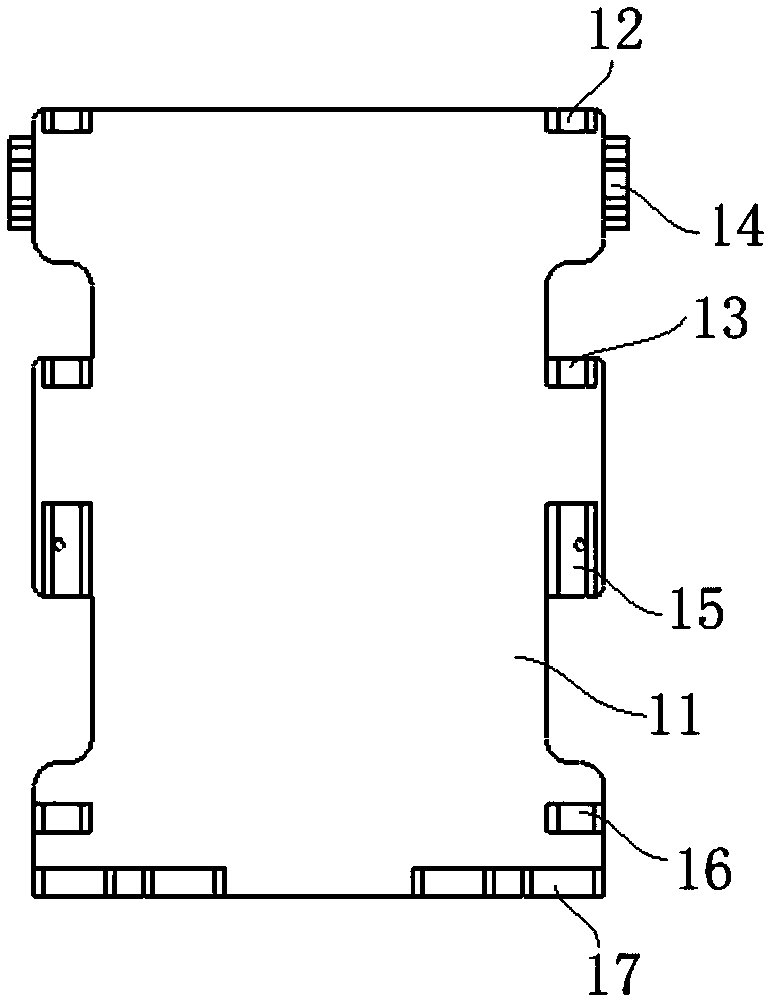

[0054] Such as Figure 1 to Figure 12 As shown, this embodiment provides a battery assembly fixture, which includes a hot melt platform 1 for a first insulating stop frame 2, a second insulating stop frame 3, and an insulating protective film 4 support Positioning.

[0055] The hot-melt platform includes a base plate 11, the upper surface of the base plate 11 includes a first end and a second end, a first positioning assembly is symmetrically distributed on both sides of the first end, and the first positioning assembly is used for the first insulating stop frame 2. For placing and positioning, there is a second positioning component on the symmetrical part on both sides of the second end, and the second positioning component is used for placing and positioning the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com