Ultrasonic atomization device and electronic cigarette

An atomizing device and ultrasonic technology, applied in the direction of tobacco, smoker's products, applications, etc., can solve the problems of endangering the health of users, unable to discharge e-liquid in time, damage to users' health, etc., and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

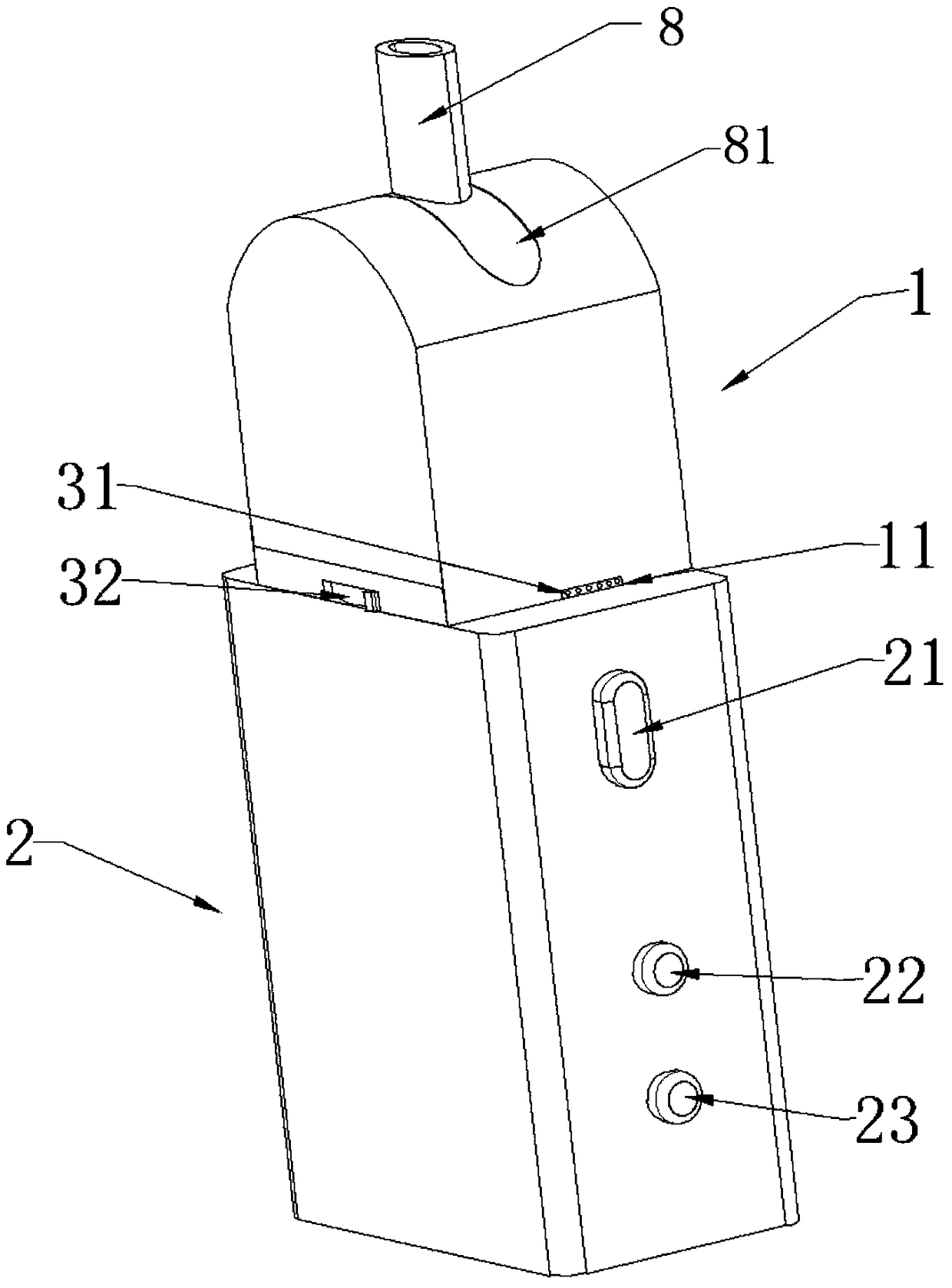

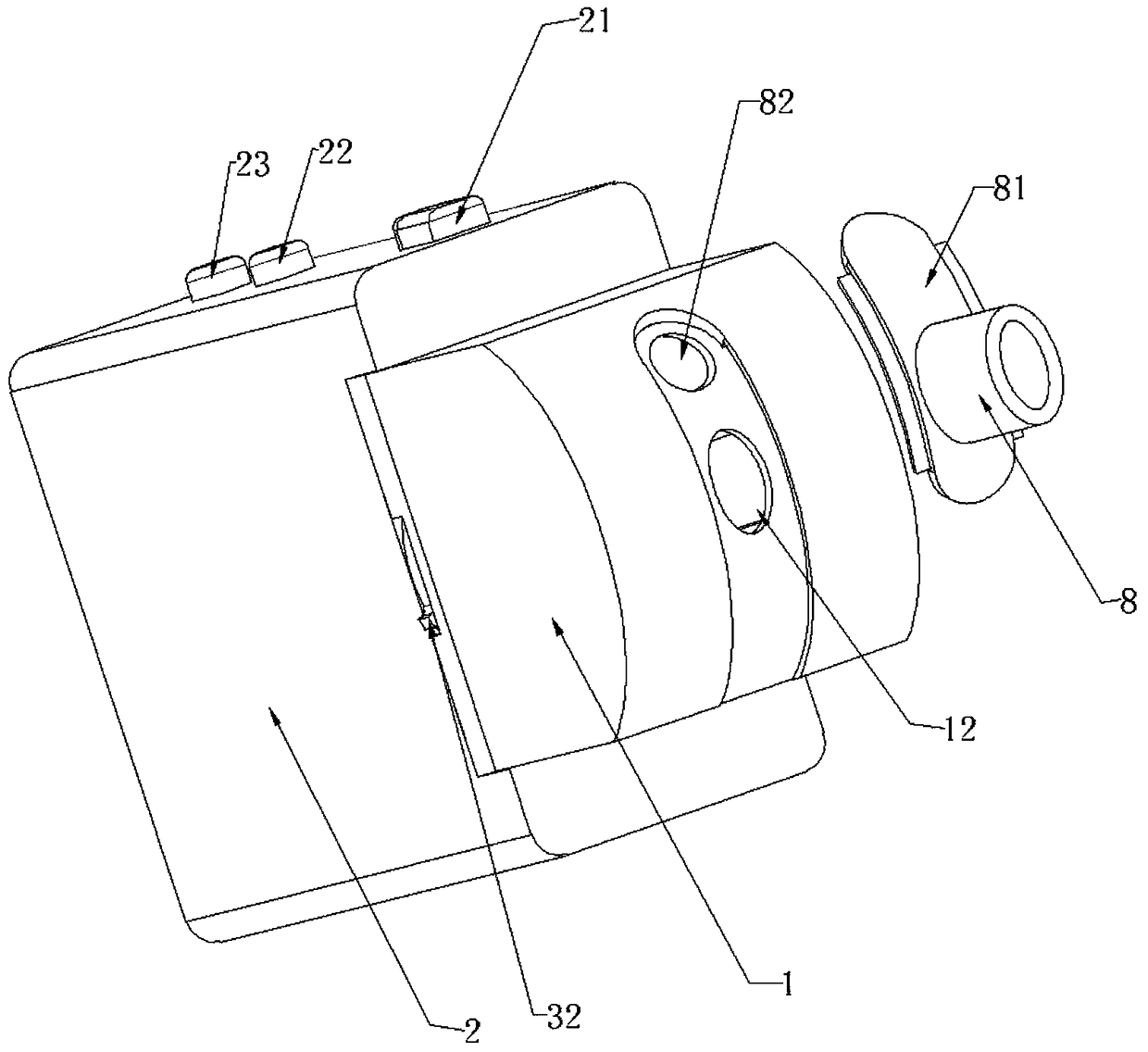

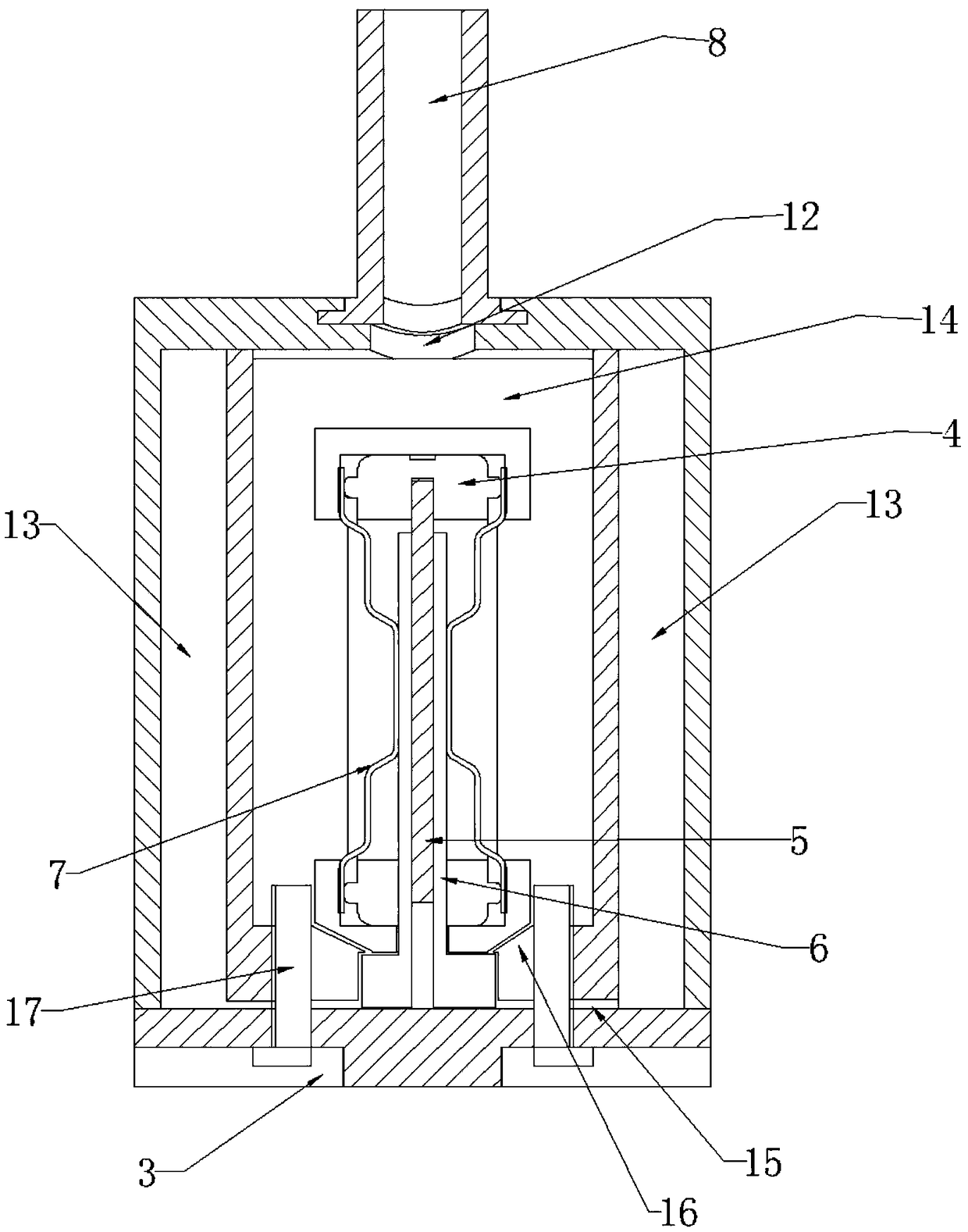

[0037] See figure 1 with figure 2 , The present invention provides an ultrasonic atomization device, including a smoke generating device 1 and a driving device 2. The smoke generating device 1 is electrically connected to the driving device 2, and the smoke generating device 1 includes an ultrasonic transducer assembly 5, a smoke oil cavity 13 and a mist The atomization cavity 14 is provided with a channel 15 connected to the e-liquid cavity 13. The atomization cavity 14 is provided with an ultrasonic transducer assembly 5, and one end of the ultrasonic transducer assembly 5 is electrically connected to the driving device 2. The outer side of the transducer assembly 5 is provided with an oil-conducting layer 6. The oil-conducting layer 6 is in contact with the e-liquid cavity 13 through the channel 15. The atomization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com