All-terrain engineering vehicle model

An engineering vehicle and all-terrain technology, applied in toy vehicles, toys, entertainment, etc., can solve the problems of small motor output torque, inability to drive on rough roads, difficulty adapting to non-structural roads, etc., to improve power performance and save driving energy The effect of consuming and increasing the mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

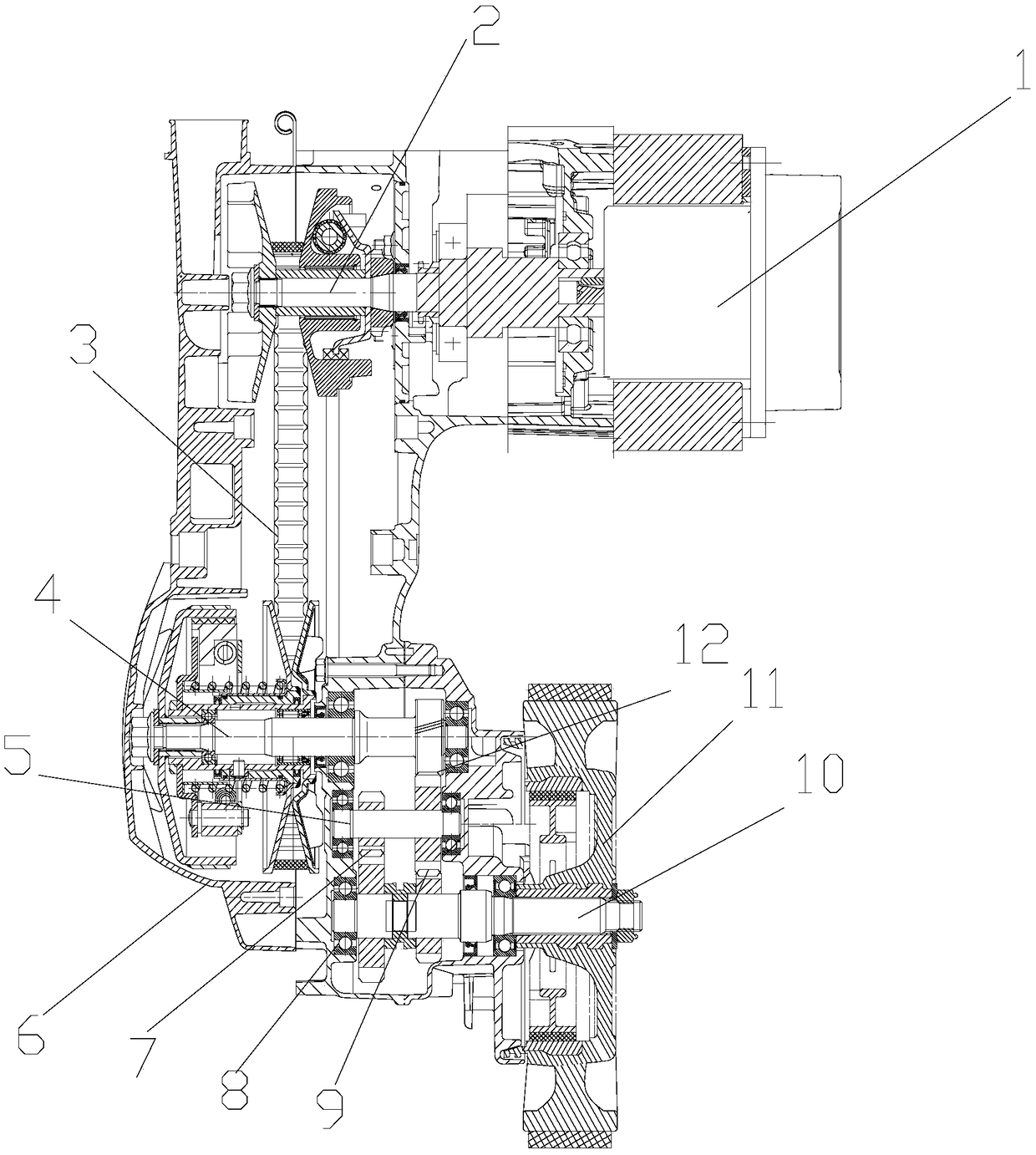

[0014] figure 1 It is a schematic structural view of the present invention, as shown in the figure, the all-terrain engineering vehicle model of the present invention includes a vehicle body 1 and a crawler chassis 14; the crawler chassis 14 includes a vehicle frame and a stepless Variable speed crawler drive system; the continuously variable crawler drive system includes a drive motor, a crawler driving wheel 14, a crawler driven wheel, a transmission that is matched to the crawler belt 16 of the crawler driving wheel 14 and a crawler guide wheel 17, and is used to drive the track driving wheel 14 and the track guide wheel 17 The power of the drive motor is transmitted to the continuously variable transmission of the track driving wheel 14;

[0015] The continuously variable transmission includes a housing 6, a first intermediate shaft 4 and a second intermediate shaft 5 that are rotatably supported in the housing 6 and are parallel to each other; the output shaft 2 of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com