I-steel overturning welding device

A technology for welding devices and I-beams, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of heavy workload, low efficiency and troublesome turning methods, and achieve improved efficiency, simplified operation, and improved turning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

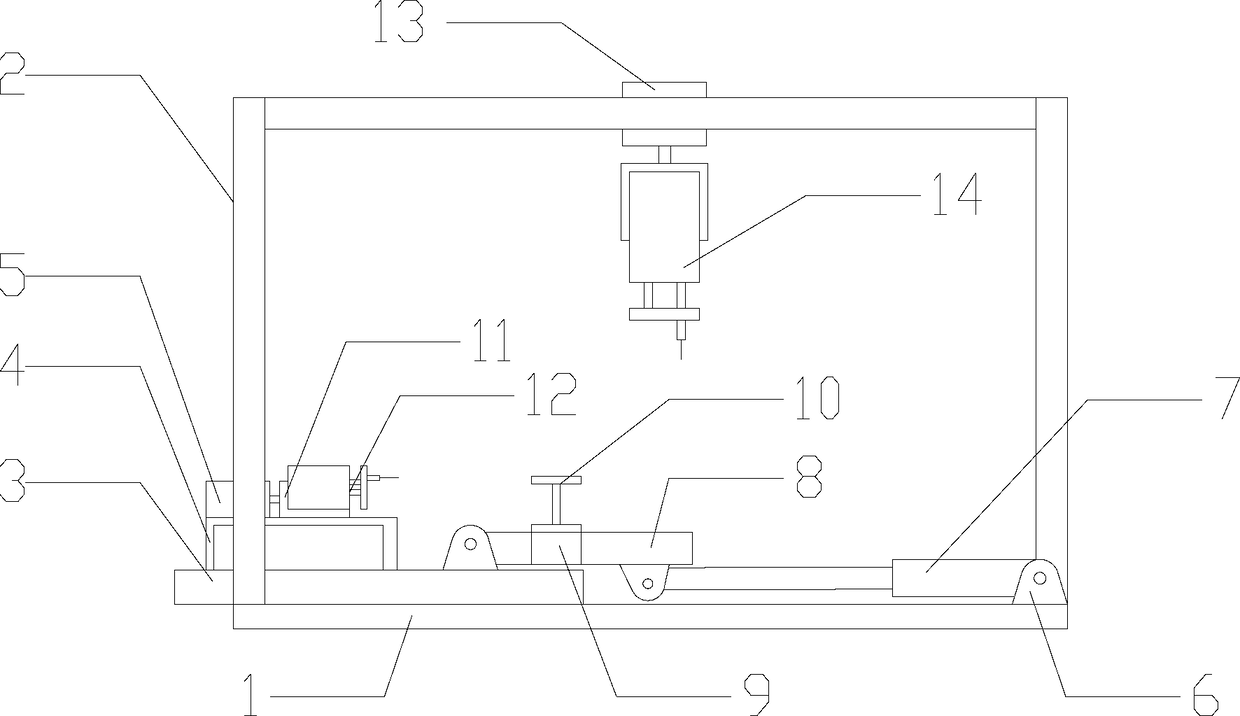

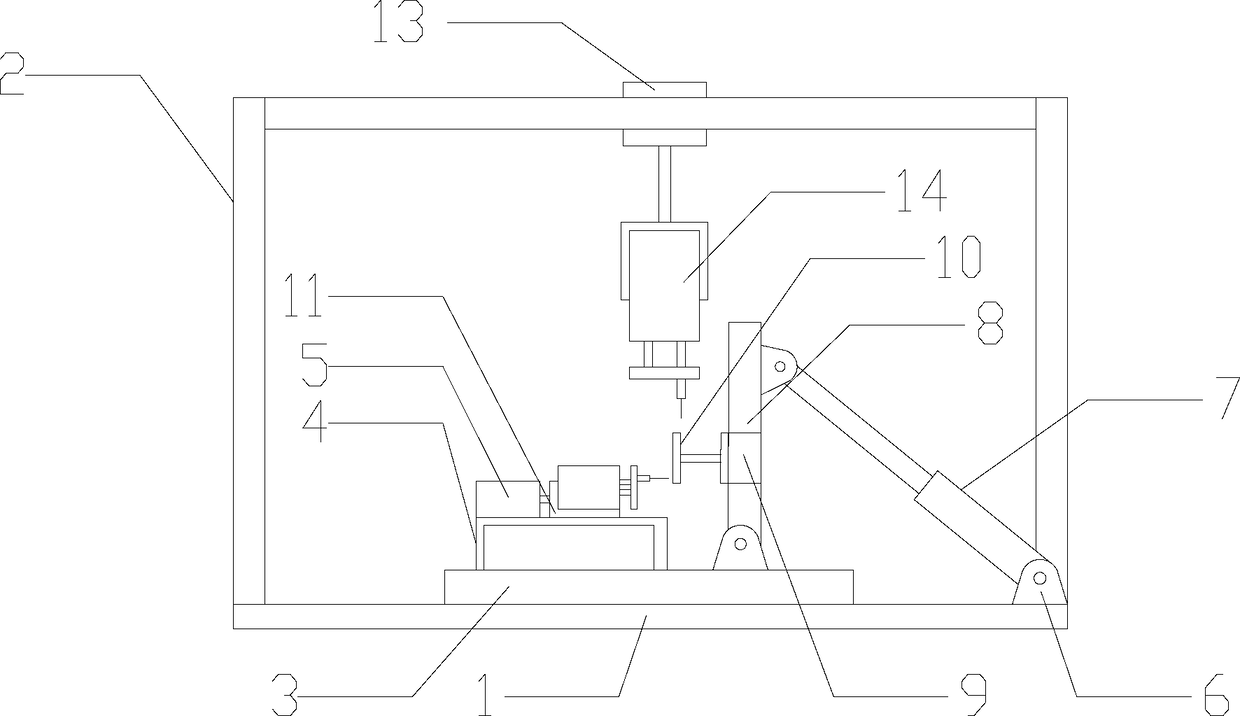

[0017] As shown in the figure, an I-beam turning welding device includes a base 1, a door frame 2 is provided on the base 1, a motor 6 is provided on one side of the base 1, one end of the telescopic rod 7 is fixed on the motor 6, and the other side of the base 1 A sliding seat 3 is provided on the top, and the sliding seat 3 can slide toward the direction of the motor 6 on the base 1. The sliding seat 3 is provided with a support 4, and the support 4 is fixed with a first hydraulic cylinder 5, and the first hydraulic cylinder 5 is fixed on the support 4. The push rod of the cylinder 5 is provided with a welding torch holder 11, the welding torch holder 11 is provided with a first welding torch 12, and the first welding torch 12 faces the direction of the motor 6 horizontally;

[0018] The door frame 2 is provided with a second hydraulic cylinder 13, the push rod of the second hydraulic cylinder 13 is vertically downward, and the push rod is provided with a second welding torch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com