Automatically-controlled pneumatic cyclone supercharger

A supercharger and pneumatic technology, which is applied in the field of swirl booster and self-control pneumatic swirl booster, can solve the problem of weak swirl strength, large loss of turbulent energy, and cannot be used in the occasions where materials pass through pipeline transportation, etc. problem, to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

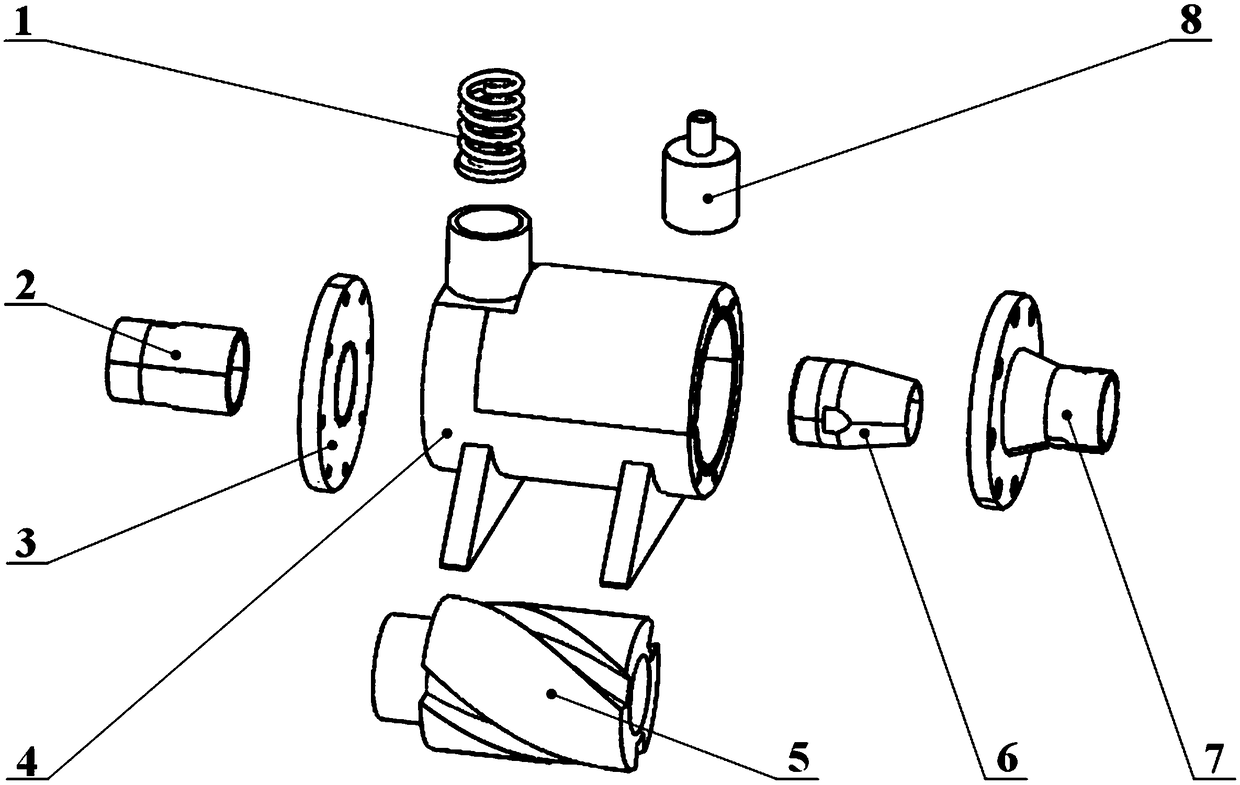

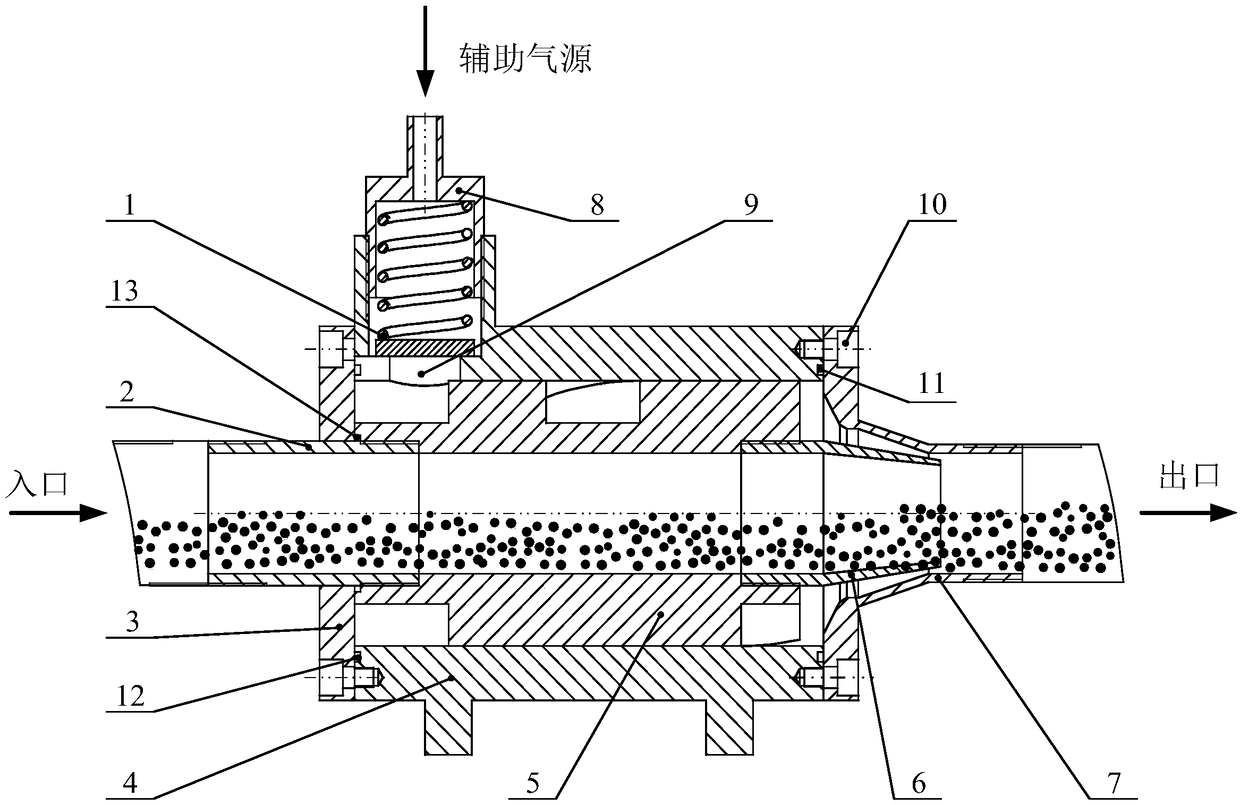

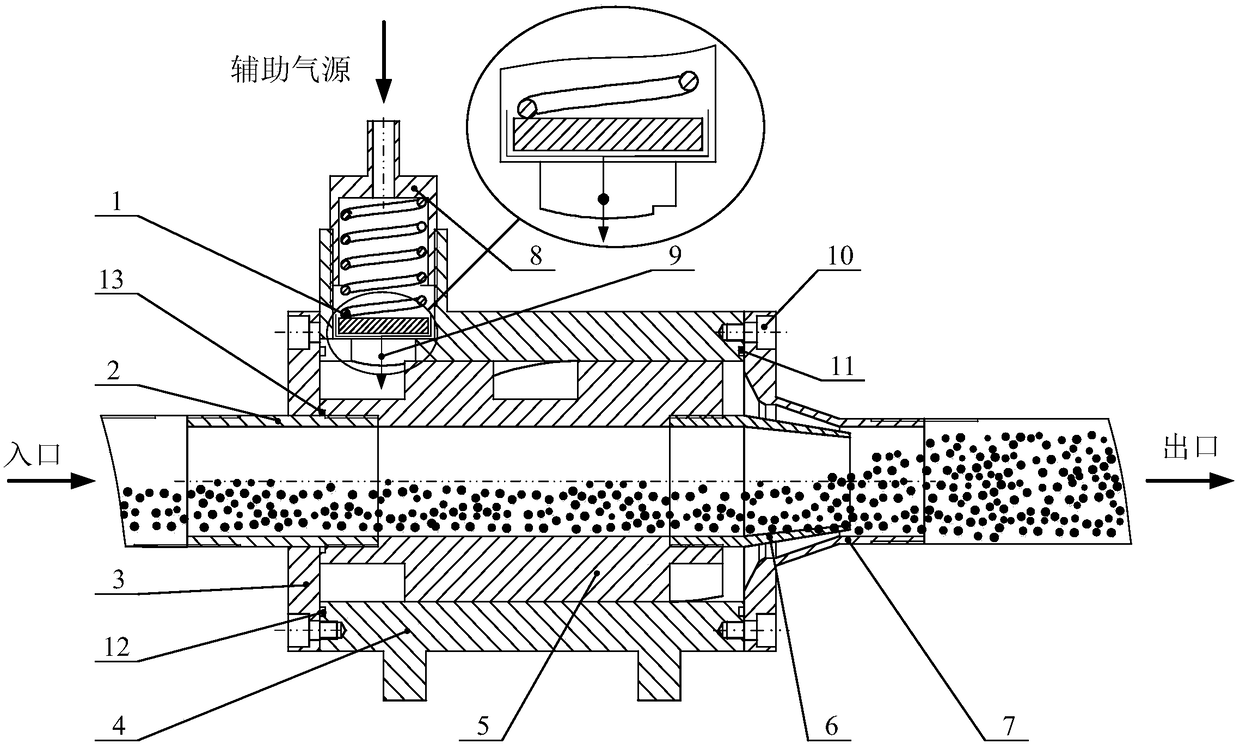

[0024] Such as Figure 1 to Figure 3 As shown, a self-control pneumatic swirl supercharger includes a housing 4, an air intake pipeline and an air outlet pipeline. There is an auxiliary air source inlet 9 on the side wall of the housing 4, and there is also a swirl vane 5 inside the housing 4. The swirl vane 5 is cylindrical, and its side wall is provided with a spiral guide groove along the axial direction. , the air inlet end of the swirl vane 5 has a stepped surface; the through hole provided at the auxiliary air source inlet 9 on the side wall of the housing 4 is a T-shaped hole, and its inner wall is provided with an internal thread, and the auxiliary air source inlet is The valve adjusting bolt 8 is installed through the thread, the upper end of the valve adjusting bolt 8 has an air intake through hole, and the lower end has a cylindrical inner cavity, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com