A new type of bridge-type ship unloader operating method

A ship unloader and bridge type technology, which is applied in the field of port bridge grab ship unloader operation, can solve the problems of increasing the horizontal and vertical deceleration time of the grab bucket, reducing the economic benefit of the enterprise, saving the operation time, etc. Bucket horizontal and vertical deceleration time, improve ship unloading efficiency, save operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

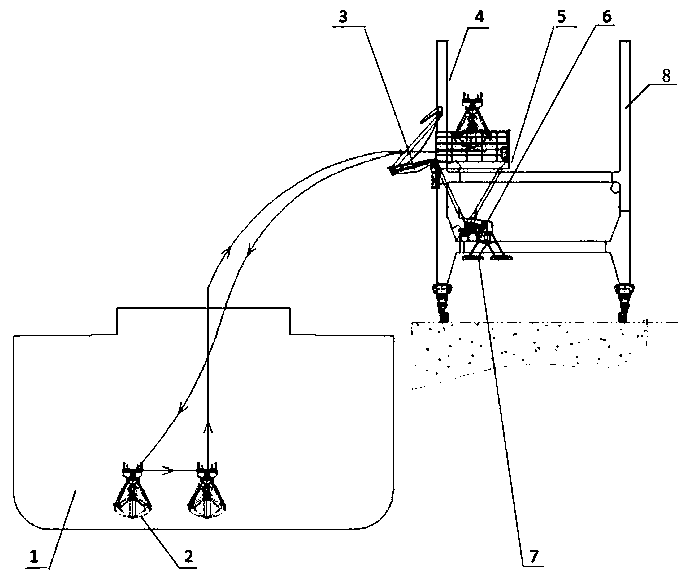

[0021] A new type of bridge-type ship unloader operation method. The bridge-type ship unloader includes a trolley 8, a grab bucket 2, a material receiving plate 3, a main body of the ship unloader 4, a funnel 5, a vibrating feeder 6 and a belt conveyor for blanking. Port 7, the trolley is located on land at the coast of the pier, matching the position of cabin 1 at sea, the operation steps are as follows:

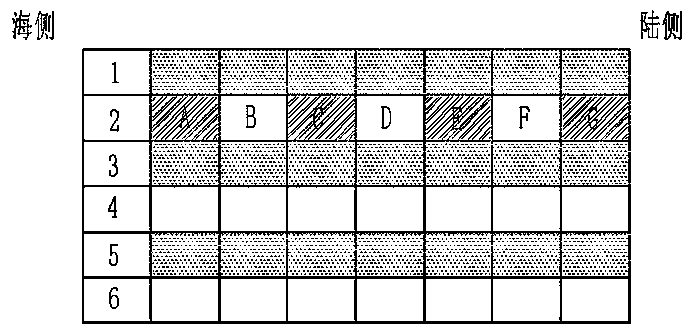

[0022] ① Divide the bulk material of the cabin 1 into several rows, and each row is divided into seven regions of the same size, namely A, B, C, D, E, F and G; each row is divided into several layers;

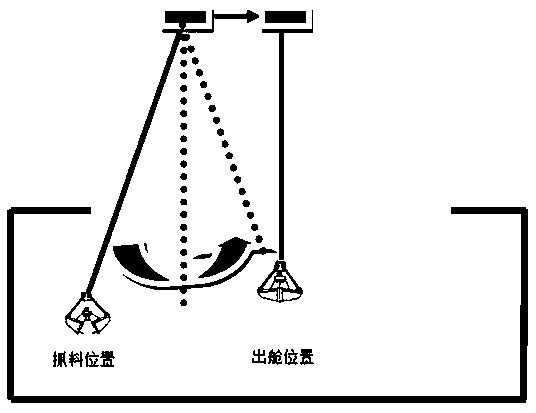

[0023] ②The trolley 8 moves towards the sea side, starts the grab bucket 2, and starts to descend at full speed when the grab bucket 2 just exceeds the receiving plate 3, and enters the cabin 1;

[0024] ③According to the height of the bulk material in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com