A construction method of homogeneous earth dam and culvert pipe through the dam for contact erosion anti-seepage grouting and detection method of grouting effect

A construction method and contact scouring technology, applied in measuring devices, infrastructure engineering, geophysical surveying, etc., can solve problems such as construction parameters relying on experience, unable to quantitatively analyze and evaluate the grouting effect, and not proposing the grouting effect, etc. To achieve the effect of good lapping effect, controllable vein direction and good thickness of pulp vein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

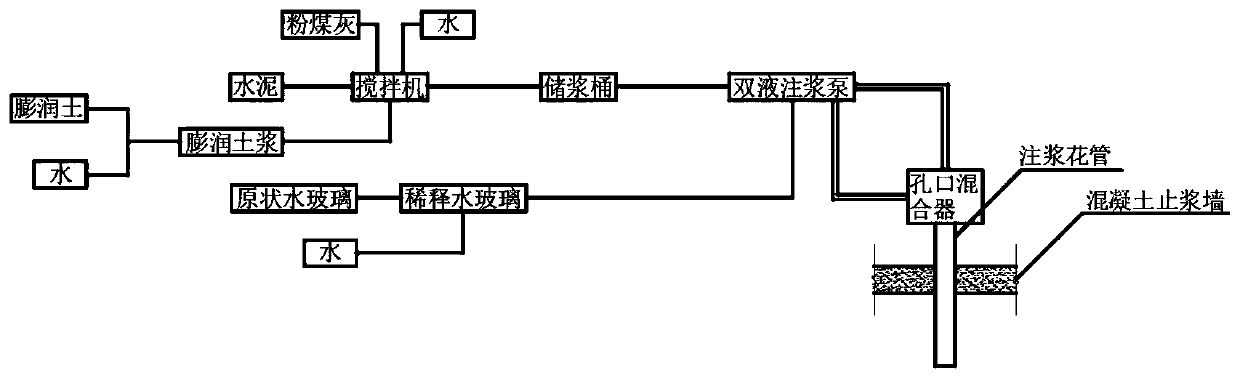

[0053] 1. Such as figure 1 As shown, a construction method for scouring and seepage prevention grouting in contact between a homogeneous earth dam and a culvert pipe through the dam includes the following steps:

[0054] Step 1: Construction preparation

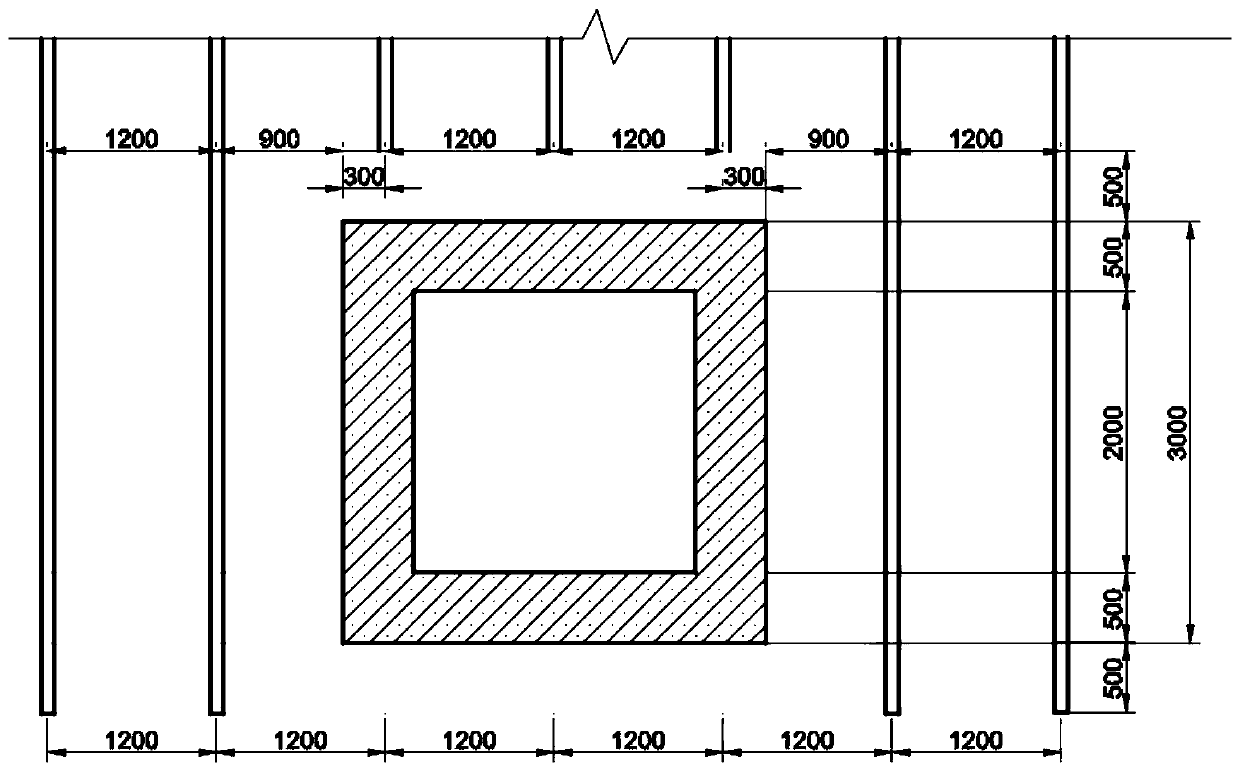

[0055] (1) Construct a grouting wall, and build a C20 spray concrete grouting wall on the grouting surface of the dam. The thickness of the grouting wall is 20cm to prevent grouting during the grouting process;

[0056] (2) Preparation of grouting construction materials and machinery, according to the requirements of grouting treatment for contact leakage between the dam of the plain reservoir and the culvert pipe passing through the dam, prepare the grouting materials used and the grouting machinery required for the grouting pressure;

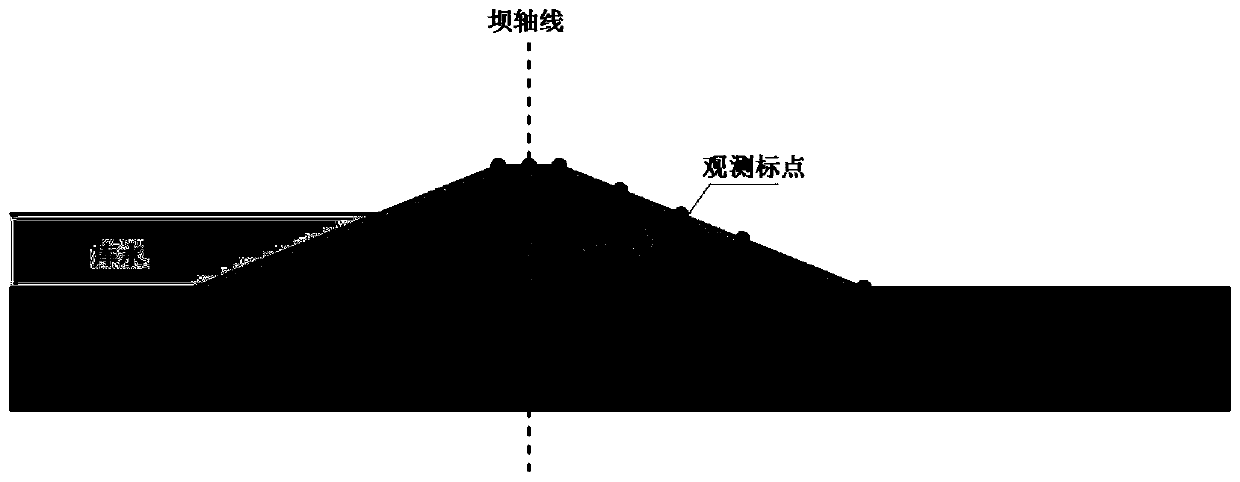

[0057] (3) The grouting monitoring points are determined. Three sets of observation punctuation points are set on the two sides of the grouting wall and the three cross-sections of the axis. The verti...

Embodiment 2

[0077] 1. A construction method for scouring and seepage prevention grouting between a homogeneous earth dam and a culvert pipe through the dam. Same as Example 1, except that in step 4, the length of the grouting section is 0.5m, and the total number of grouting is 2 times. In step 5 , The density of thick slurry is 1.8t / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com