Roadbed widening method

A technology for roadbed and soil roadbed, applied in the directions of roads, filling, excavation, etc., can solve problems such as insufficient stability, and achieve the effects of fast construction, improved stability, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

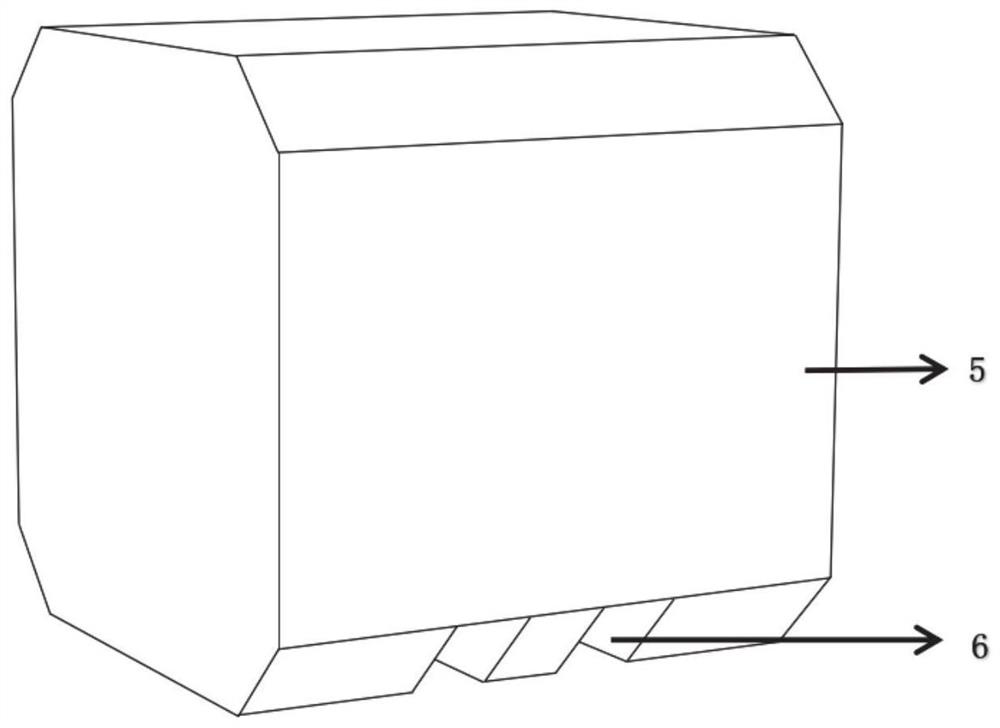

[0035] This embodiment discloses a roadbed widening method. The roadbed is widened by using a widening structure composed of foam light soil roadbed blocks and a retaining wall. The widening structure formed by the foam lightweight soil roadbed blocks is overlapped with the original roadbed to widen the original roadbed, and the retaining wall is in contact with the outer surface of the widening structure to bear the horizontal lateral force generated by the widening structure , to ensure the stability of the subgrade structure.

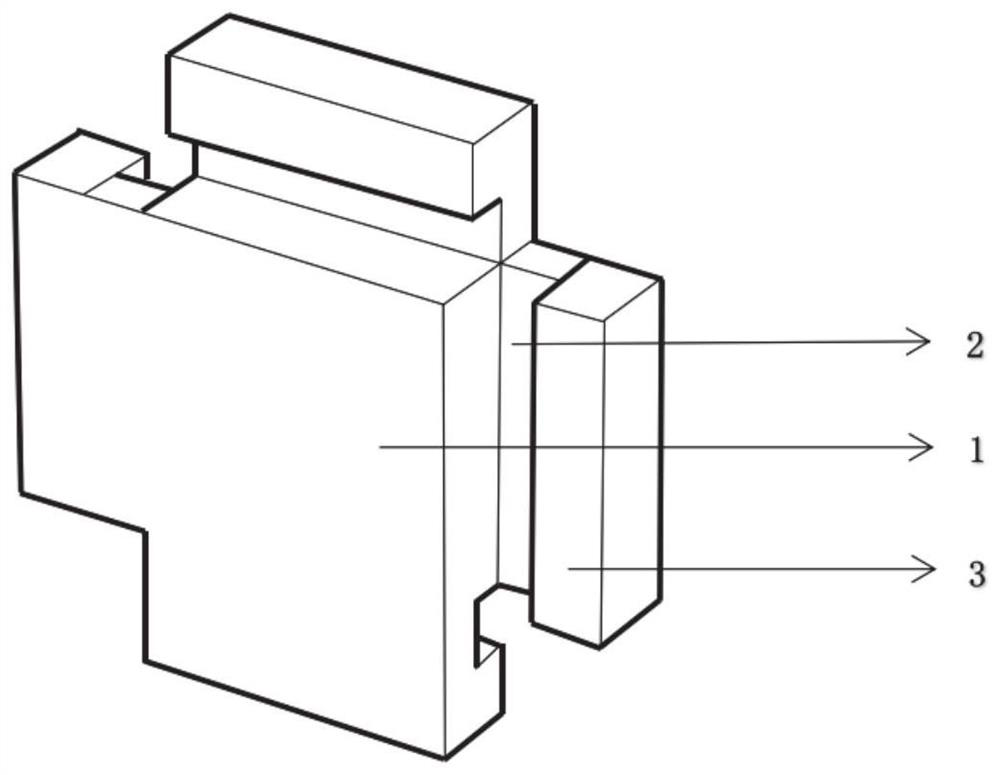

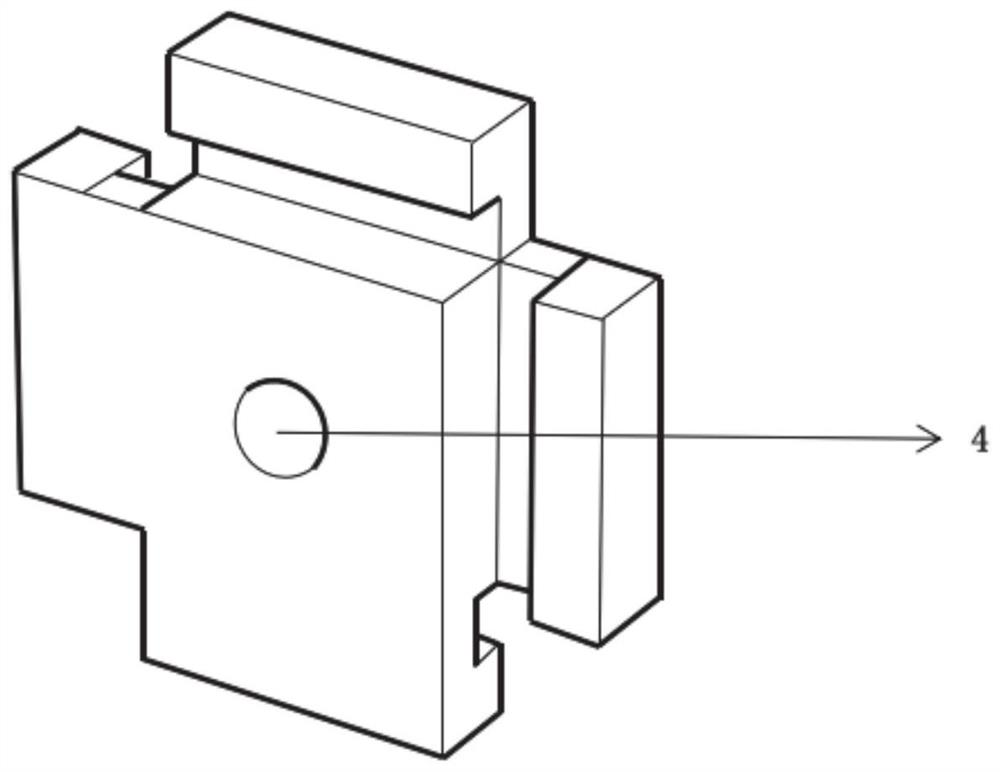

[0036] Such as figure 1 As shown, the retaining wall can be formed by splicing a plurality of retaining wall modules, the retaining wall module includes a module body 1, the four sides of the module body are provided with a splicing structure, and adjacent retaining wall modules can be connected through the splicing structure. splice connection.

[0037] The splicing structure adopts an L-shaped structure, including a first splicing part 2 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com