Homogeneous earth dam and dam penetrating culvert pipe contact scouring anti-seepage grouting construction method and grouting effect detection method

A construction method and contact scouring technology, applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problem of relying on experience in construction parameters, unable to quantitatively analyze and evaluate the grouting effect, unable to play the role of grouting anti-seepage and Reinforcement and other issues, to achieve the effect of good lap joint effect, good plasma vein thickness, and controllable plasma vein direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

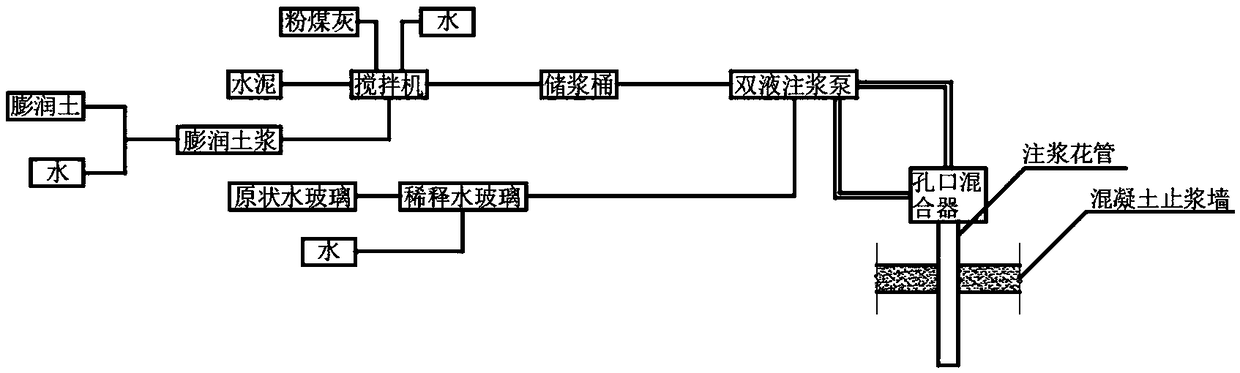

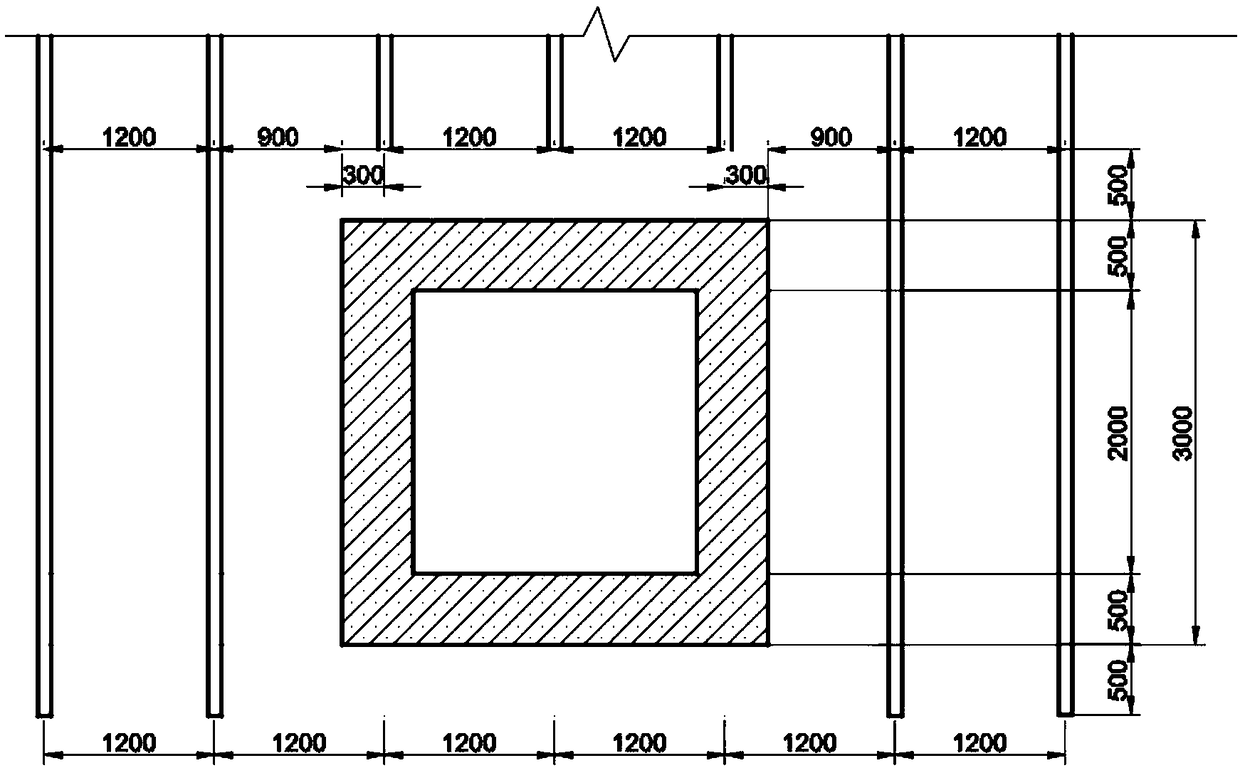

[0053] 1. If figure 1 Shown, a kind of homogeneous earth dam and dam-piercing culvert contact scour anti-seepage grouting construction method, comprise the following steps:

[0054] Step 1: Construction preparation

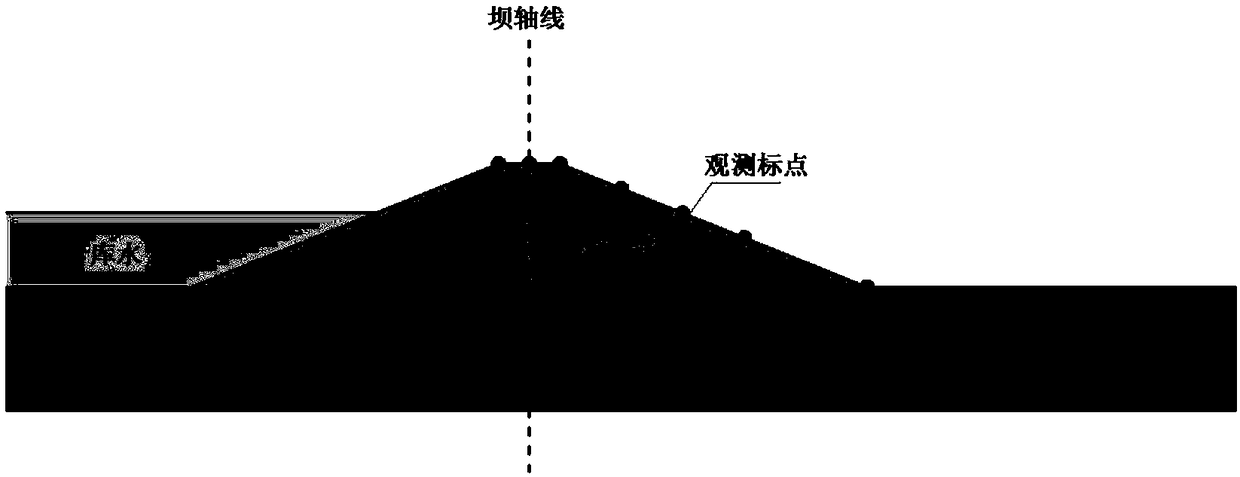

[0055] (1) Build a grout stop wall, build a C20 sprayed concrete grout stop wall on the grouting surface of the dam, the thickness of the grout stop wall is 20cm, to prevent the grout from escaping during the grouting process;

[0056] (2) Grouting construction materials and mechanical preparations, according to the requirements of grouting treatment for contact leakage between the dam of the plain reservoir and the culvert pipe, prepare the grout materials used and the grouting machinery required for the grouting pressure;

[0057] (3) The grouting monitoring points are determined. Three groups of observation points are set on the two side lines and three sections of the axis of the grout stop wall, and the vertical deformation of each point is observed with a l...

Embodiment 2

[0077] 1. A construction method of homogeneous earth dam and dam-piercing culvert contact erosion anti-seepage grouting construction method, the same as embodiment 1, the difference is that in step 4, the grouting segment length is 0.5m, and the total pouring times is 2 times, in step 5 , thick pulp density is 1.8t / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com