Special gear assembly connecting shaft

A technology of gear connection and shaft connection, which is applied in the direction of belt/chain/gear, shaft, shaft and bearing, etc. It can solve the problems of poor connection tightness, shortened gear structure life, and affecting the normal use of the gear structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

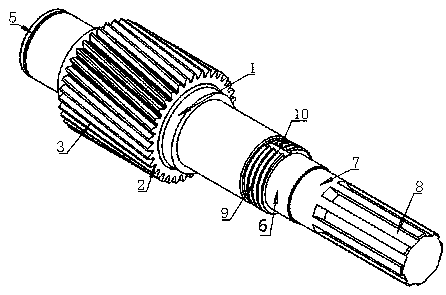

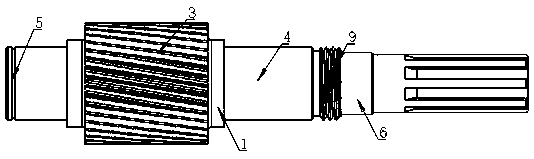

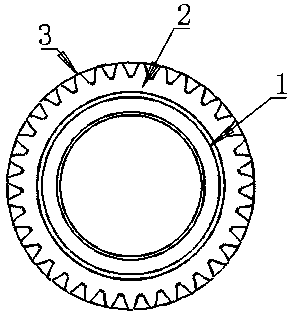

[0016] Such as Figure 1 to Figure 5 As shown in the figure, a special gear assembly connecting shaft is mainly engaged with the helical gear structure when used. Its structural strength is relatively high, and its structural stability is more reliable in the process of adjusting and rotating, and its service life is longer. Longer, the connecting shaft is provided with an anti-loose fastening connecting column on the connecting shaft, and a threaded anti-loose fastening structure is set on the anti-loose fastening connecting column, so that it can be better connected with mechanical equipment during assembly. At the same time, the safety of this part and the gear structure is higher, and the firmness of the connection is more reliable. During assembly, the anti-loosening positioning groove provided on the structure can make the accuracy of the assembly position higher, and the assembly is more accurate. It is convenient, so that it can rotate better during use, and the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com