Light-heat conversion energy-saving technology for fluid conveying pipeline

A light-to-heat conversion and fluid transportation technology, which is applied in pipeline heating/cooling, pipeline protection, heat exchange equipment, etc., can solve the problems of high energy consumption for heating pipelines, high cost and time for maintenance and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

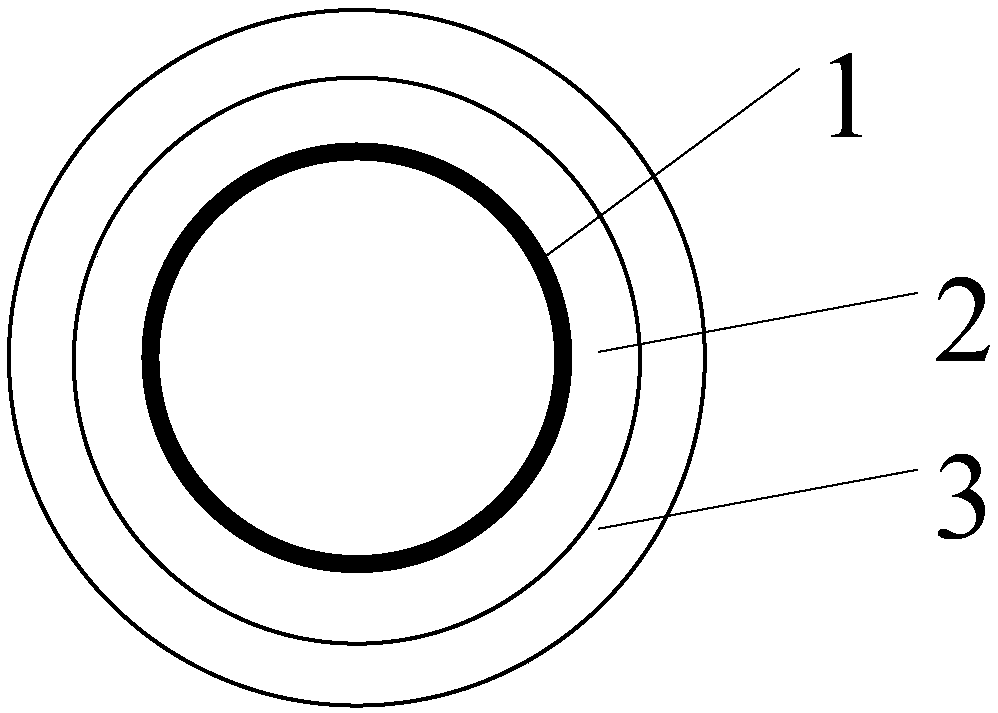

[0018] Please check figure 1 , the light-to-heat conversion energy-saving technology for fluid conveying pipelines includes an inner pipe 1, an insulation layer 2 and a light-to-heat conversion material layer 3, the heat-insulation layer 2 is set on the outer wall of the inner pipe 1 to maintain temperature; the light-to-heat conversion material layer 3 covers On the outside of the insulation layer 2, the light-to-heat conversion material layer 3 converts sunlight into heat. like figure 1 As shown, the light-to-heat conversion material layer 3 is coated on the outer side of the thermal insulation layer 2 . The material of the insulation layer 2 can be selected from at least one of polyurethane foam, phenolic foam, glass wool, rock wool and expanded perlite.

[0019] Photothermal conversion materials refer to materials that concentrate solar radiation energy by reflection, absorption or other means and convert it into a sufficiently high temperature. Photothermal conversion ...

Embodiment 2

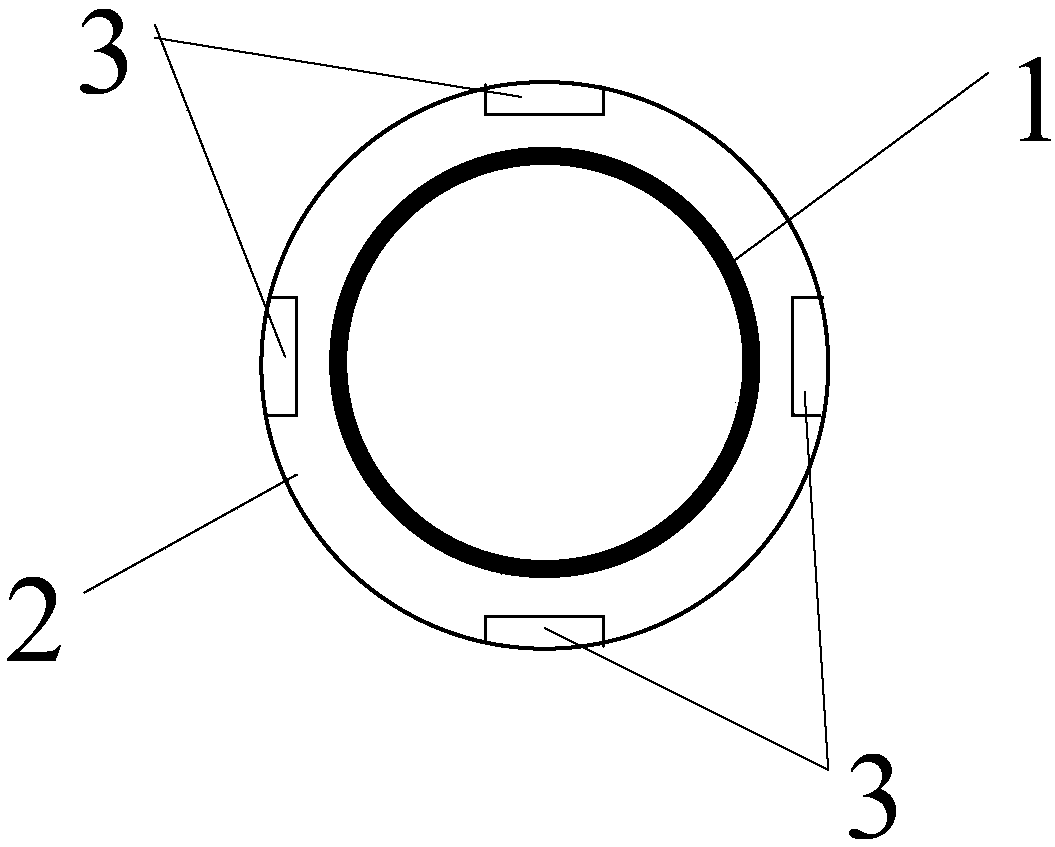

[0030] Please check figure 2 , the light-to-heat conversion energy-saving technology for fluid conveying pipelines includes an inner pipe 1, an insulation layer 2 and a light-to-heat conversion material layer 3, the heat-insulation layer 2 is set on the outer wall of the inner pipe 1 to maintain temperature; the light-to-heat conversion material layer 3 covers On the outside of the insulation layer 2, the light-to-heat conversion material layer 3 converts sunlight into heat. like figure 2 As shown, the light-to-heat conversion material layer is nested outside the insulation layer. The material of the insulation layer 2 can be selected from at least one of polyurethane foam, phenolic foam, glass wool, rock wool and expanded perlite.

[0031] When the pipeline transports fluid, the light-to-heat conversion material layer 3 covers the outer side of the insulation layer 2, and the light-to-heat conversion material layer 3 absorbs sunlight and converts sunlight into heat withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com