A Test Apparatus and Method for Evaluating Scattering and Construction Depth of Drained Asphalt Pavement

A technology for constructing depth and draining asphalt, which is applied in the directions of measuring devices, strength characteristics, testing wear resistance, etc., and can solve problems that affect the durability of asphalt pavement, driving comfort, asphalt mixture particles flying, and road pits and grooves. Achieve the effect of small influence of human factors, simple equipment structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

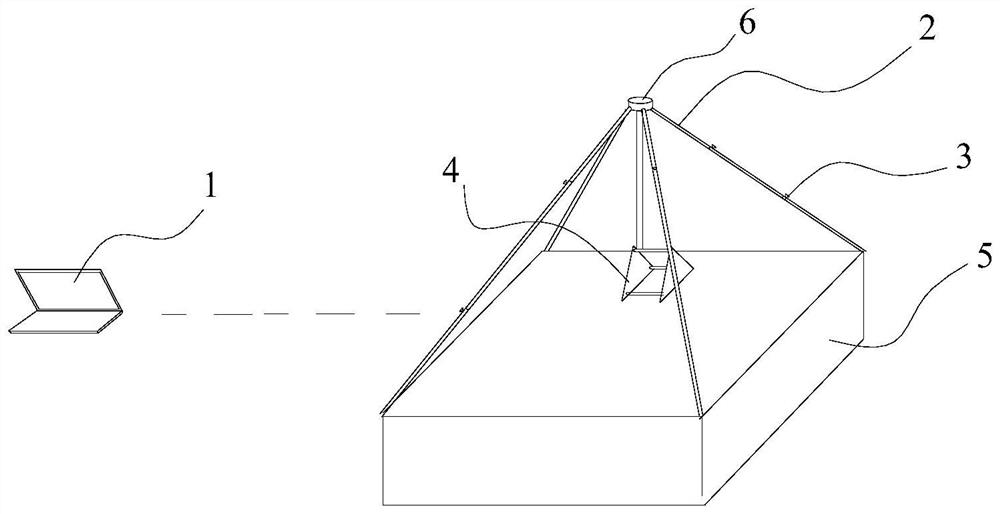

[0032] see figure 1 and figure 2 , a test device for evaluating the spattering and construction depth of drainage asphalt pavement, including: a three-dimensional laser scanner 7, a fixed bracket and a notebook computer 1,

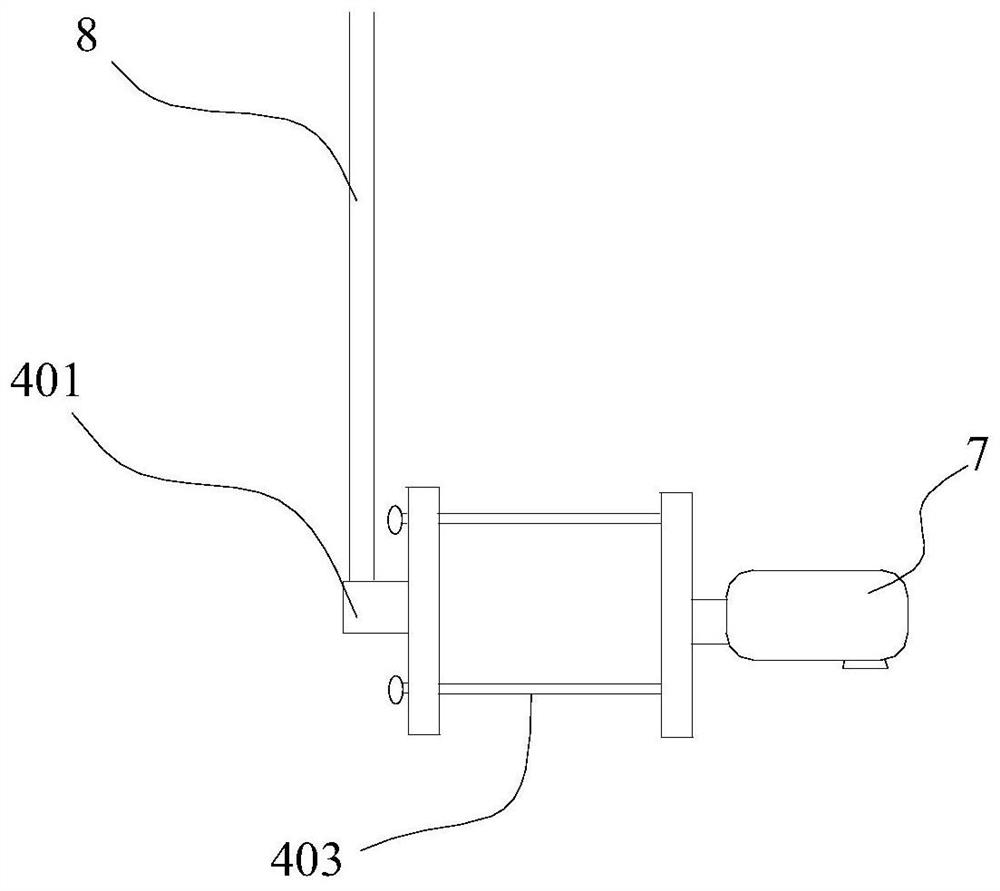

[0033] The fixed support is a four-legged support, and the carrying platform 4 is connected to the support by connecting rods 8. The three-dimensional laser scanner 7 is placed on the carrying platform; the three-dimensional laser scanner is connected to the notebook computer 1 through communication.

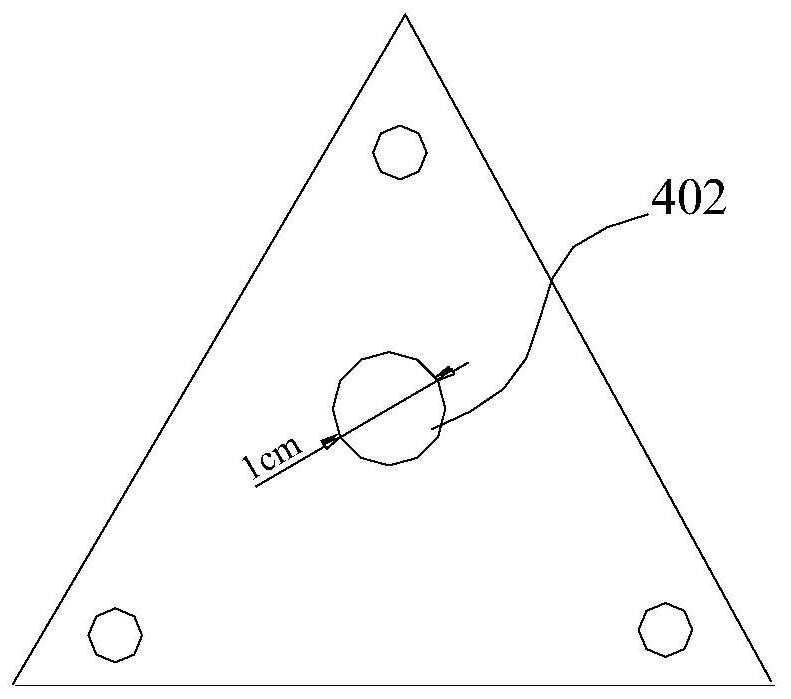

[0034] In this embodiment, the fixed bracket is supported by four extensible pipes 2, the extensible pipes are sleeve structures, the pipes are provided with bolts 3, the sleeves are stretched or retracted to change the length, the bolts 3 are Tighten it after adjusting the length. The top of the fixed bracket is provided with a rotary joint 6 for fixing the pipe. The rotary joint 6 is made of plastic material, and the tops of the four pipes are fixed to...

Embodiment 2

[0045] A test device for evaluating the spattering and construction depth of drained asphalt pavement, including: a three-dimensional laser scanner 7, a fixed bracket and a notebook computer 1.

[0046] The fixed bracket is a tripod-supported bracket, and the mounting platform 4 is connected to the bracket by connecting rods. The three-dimensional laser scanner 7 is placed on the loading platform; the three-dimensional laser scanner is connected to the notebook computer 1 through communication.

[0047] In this embodiment, the fixed bracket is supported by three extensible pipes 2, the extensible pipes are sleeve structure, the pipes are provided with bolts 3, the sleeves are stretched or retracted to change the length, the bolts 3 are adjusted Tighten and fix after a good length. The top of the fixed bracket is provided with a rotary joint 6 for fixing the pipe. The rotary joint 6 is made of metal, and the tops of the four pipes are fixed together by the rotary joint. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com