Small-corner pantograph head design method

A pantograph and corner technology, applied in design optimization/simulation, calculation, current collectors, etc., can solve the problems of long calculation and analysis process cycle, long design cycle, topology structure change, etc., and achieve simple and efficient modification or addition of parameters. Reduce pantograph and catenary damage, optimize and solve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific optimization steps of the present invention are as follows:

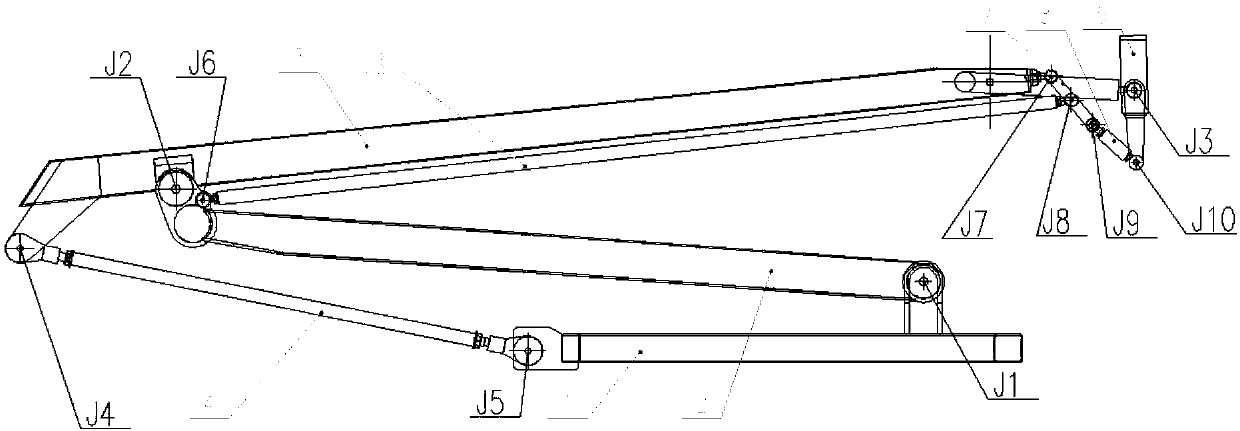

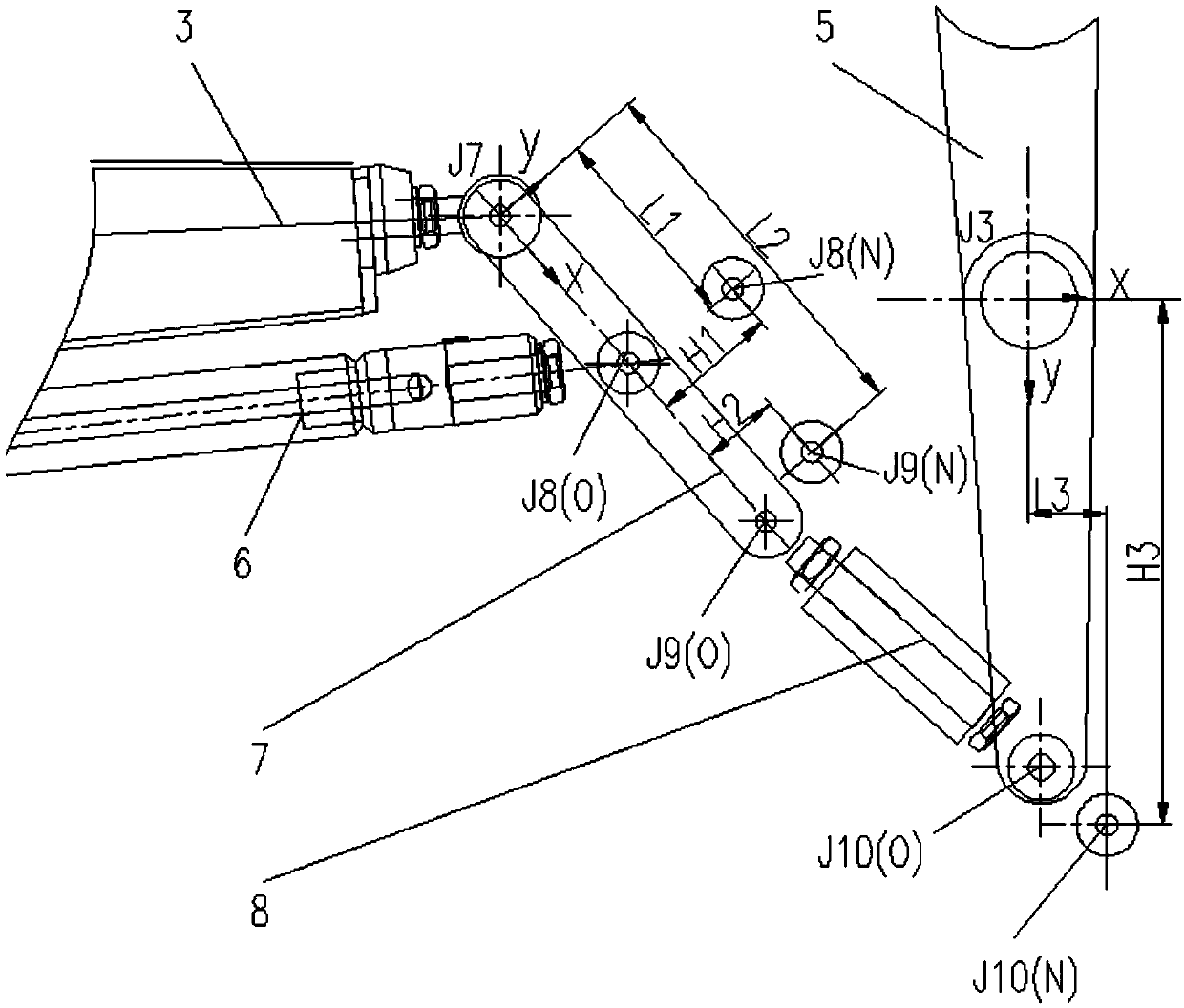

[0034] (1) Establish a non-parametric pantograph dynamics model in general dynamics software (such as SIMPACK, RECURDYN, ADAMS, etc.) according to the pantograph design scheme. On the basis of the initial graphic geometry of existing 3D CAD software (such as UG, etc.), taking the pantograph scheme in Figure 1 as an example, the process of establishing a non-parametric pantograph dynamics model is explained.

[0035] Establish the parts and geometry of the non-parametric pantograph dynamic model, input the three-dimensional geometry of each part 1-8 in the dynamic software in turn, if a part is composed of several parts, merge this part in the dynamic software The parts form the same Part (software term), the software will select the material of the part as steel by default, you can choose the material in the software library or assign the weight directly to the part, the software will automatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com