Ball socket joint and toy

A ball-socket joint and ball-joint technology, which is used in toys, dolls, entertainment, etc., can solve the problems of lack of rigidity, easy deformation, and impracticality, and achieve the effect of improving realistic effect, large rotation angle and range of motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

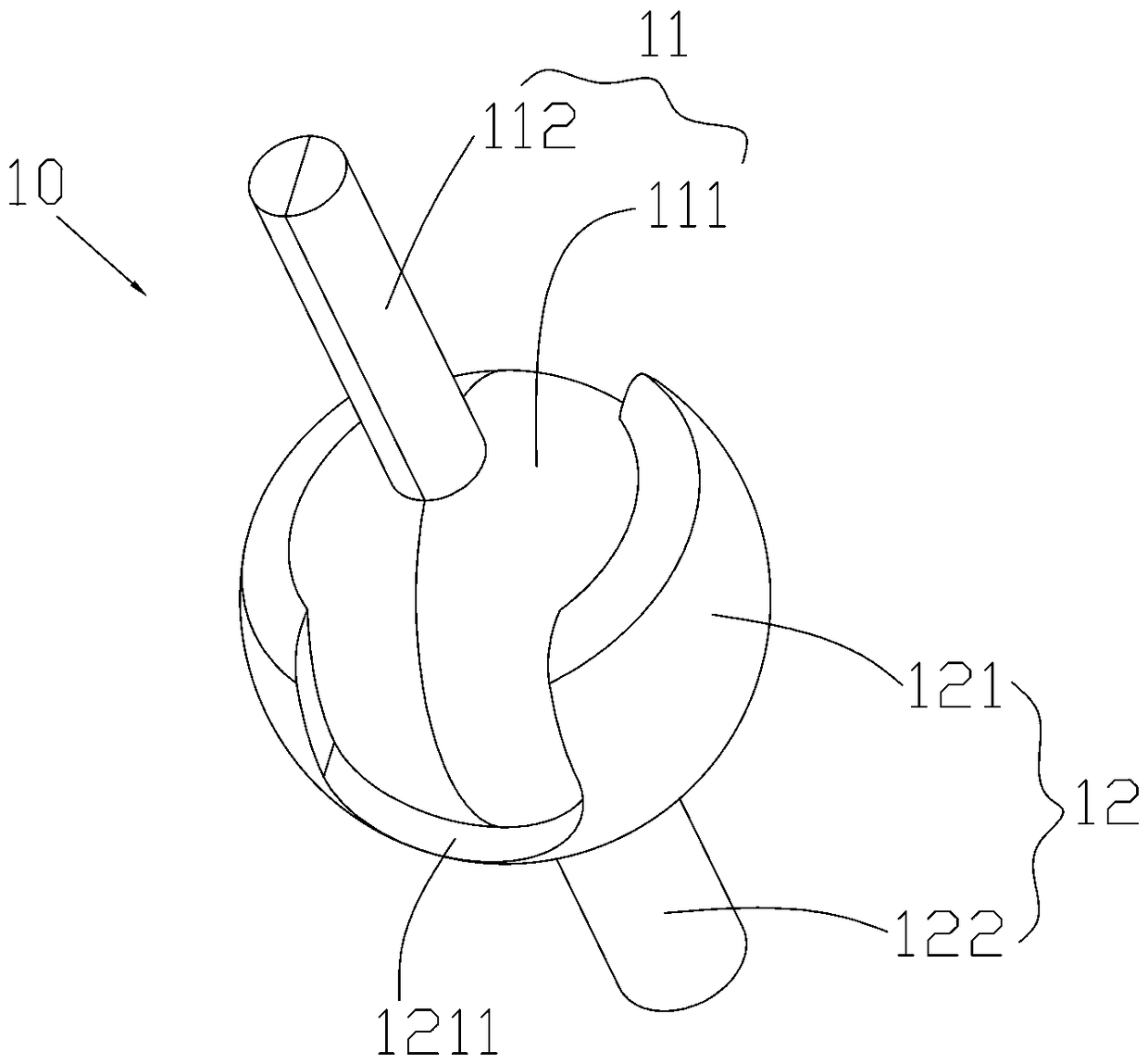

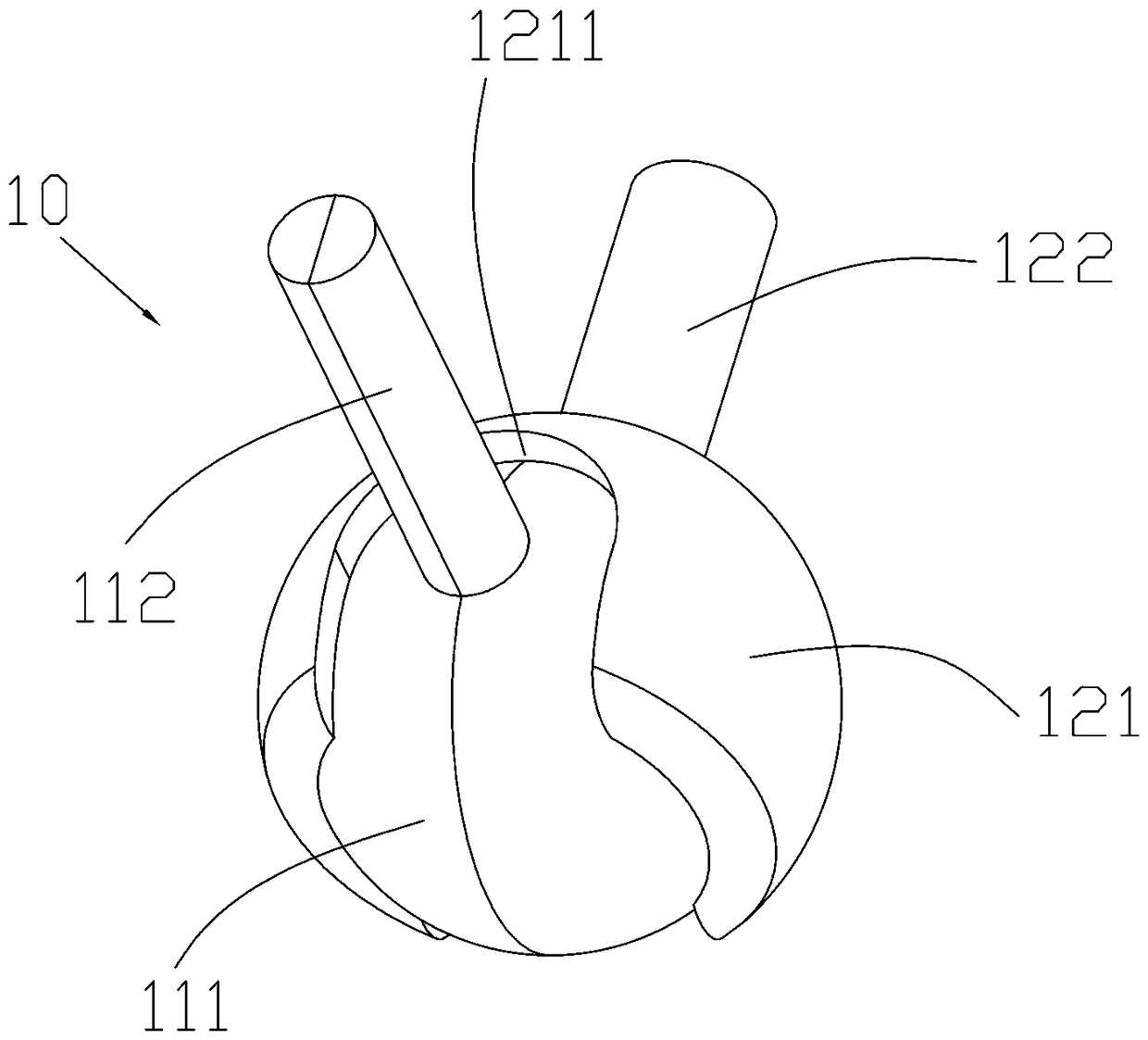

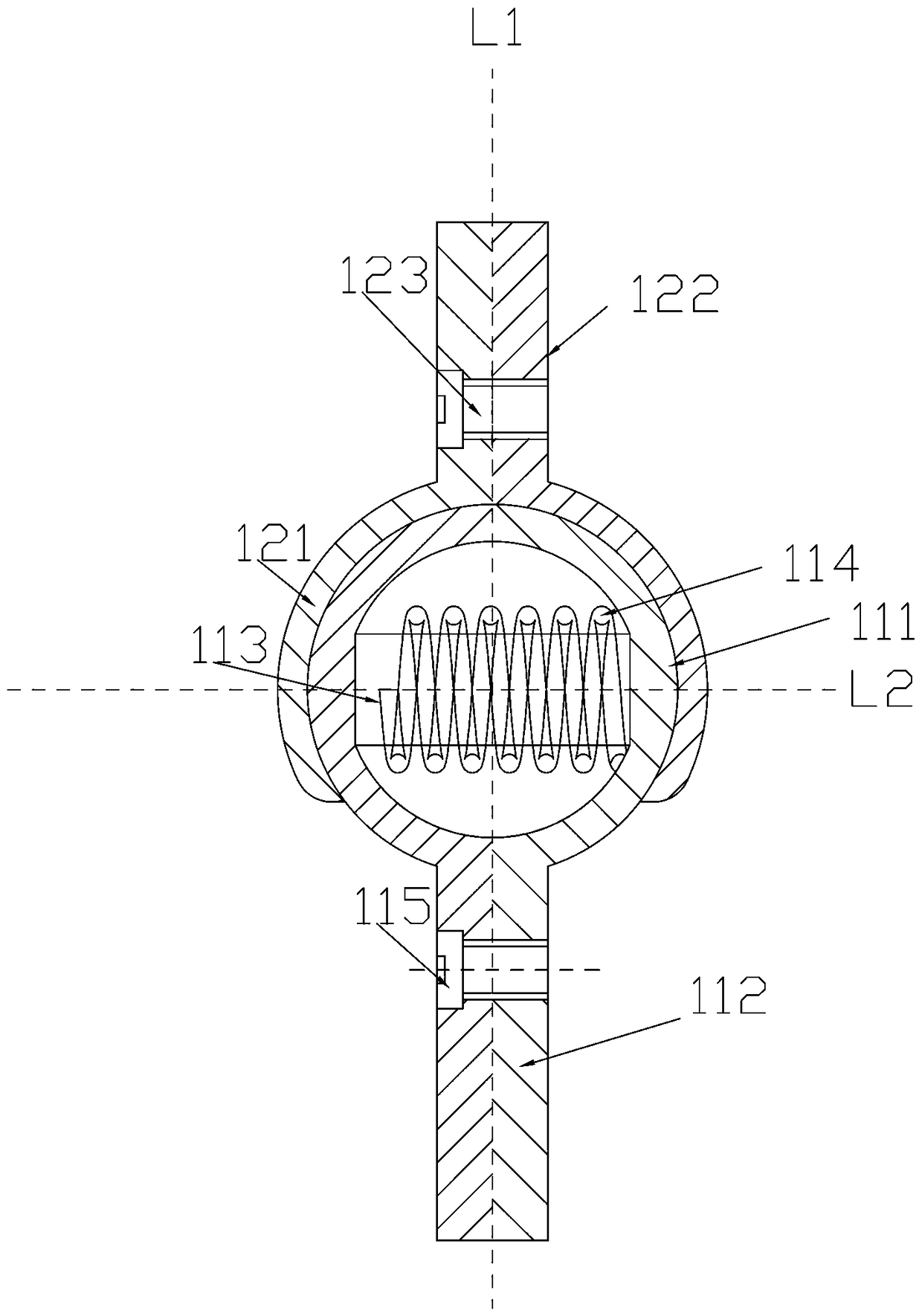

[0031] Refer below Figure 1-Figure 5 The ball joint 10 of the embodiment of the present invention will be described.

[0032] Such as figure 1 and Figure 4 As shown, the ball joint 10 of the present invention has a ball joint part 11 and a ball socket part 12 that can rotate with each other.

[0033] The ball joint part 11 includes a ball joint 111 and a first circumscribed shaft 112 arranged on the outer surface of the ball joint 111. The first circumscribed shaft 112 is used to connect other external components. The axis of the first circumscribed shaft 112 is defined as vertical The straight line L1, perpendicular to the vertical line L1 is the horizontal line L2. Then the ball joint 111 and the first circumscribed shaft 112 are all on the same horizontal line, that is, the horizontal line L2 is split into two halves in opposite directions, and the ball joints 111 that are split into two halves are elastically connected, and the first circumscribed shaft that is split ...

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The same parts will not be described in detail, and only the different parts will be described. The shaft has elasticity, so that the disassembled ball joint 111 moves back and forth on the horizontal line L2, so that the outer surface of the ball joint 111 abuts against or leaves the inner surface of the ball bushing 121, so that the ball joint 111 can be moved according to the movement Smoothness needs to be adjusted automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com