Processing apparatus for ink

A processing device and ink technology, which is applied to mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve the problems of long upward moving distance of stirring rods, low working efficiency, and high cylinder damage rate, and achieves service life. The effect of increasing work efficiency and shortening time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

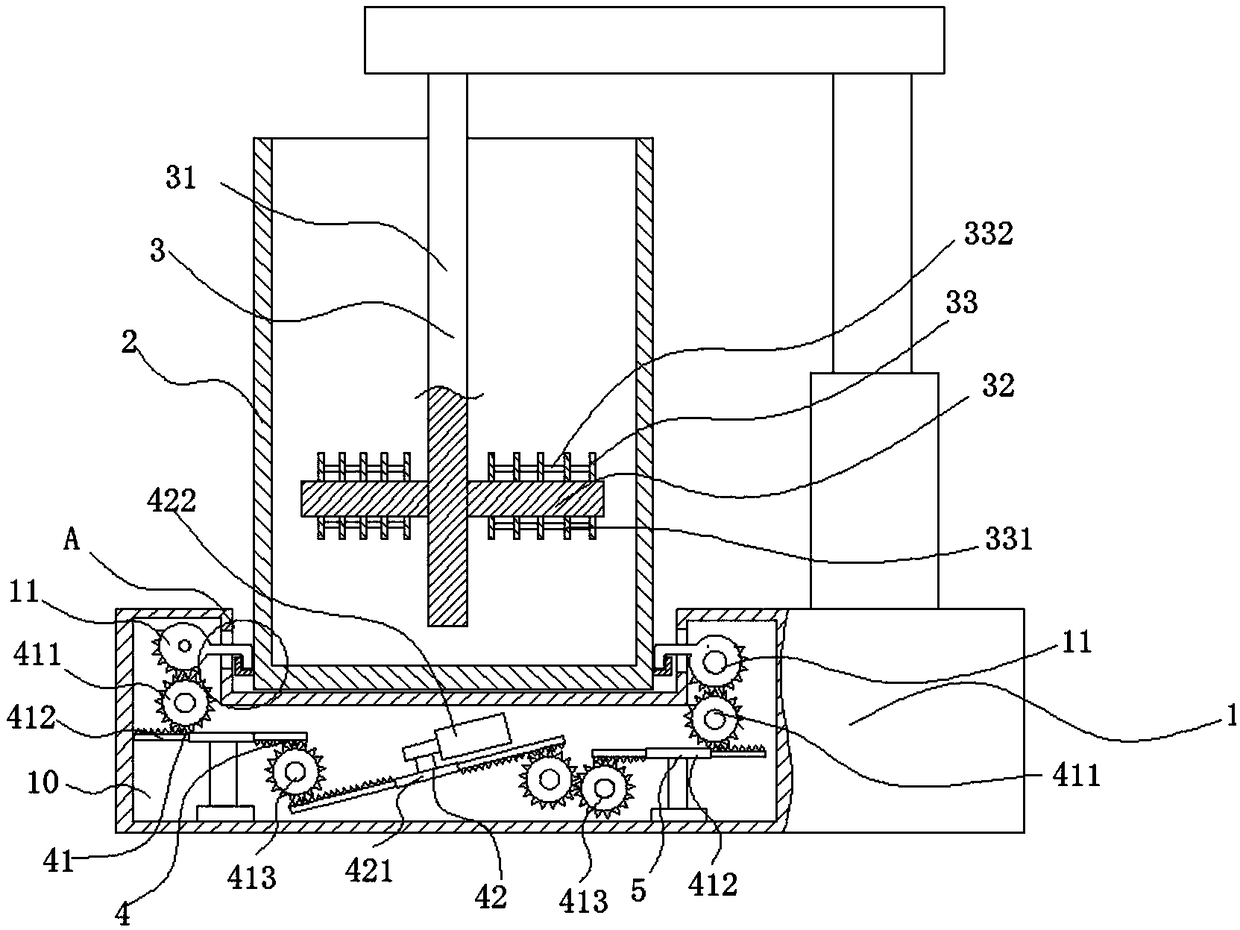

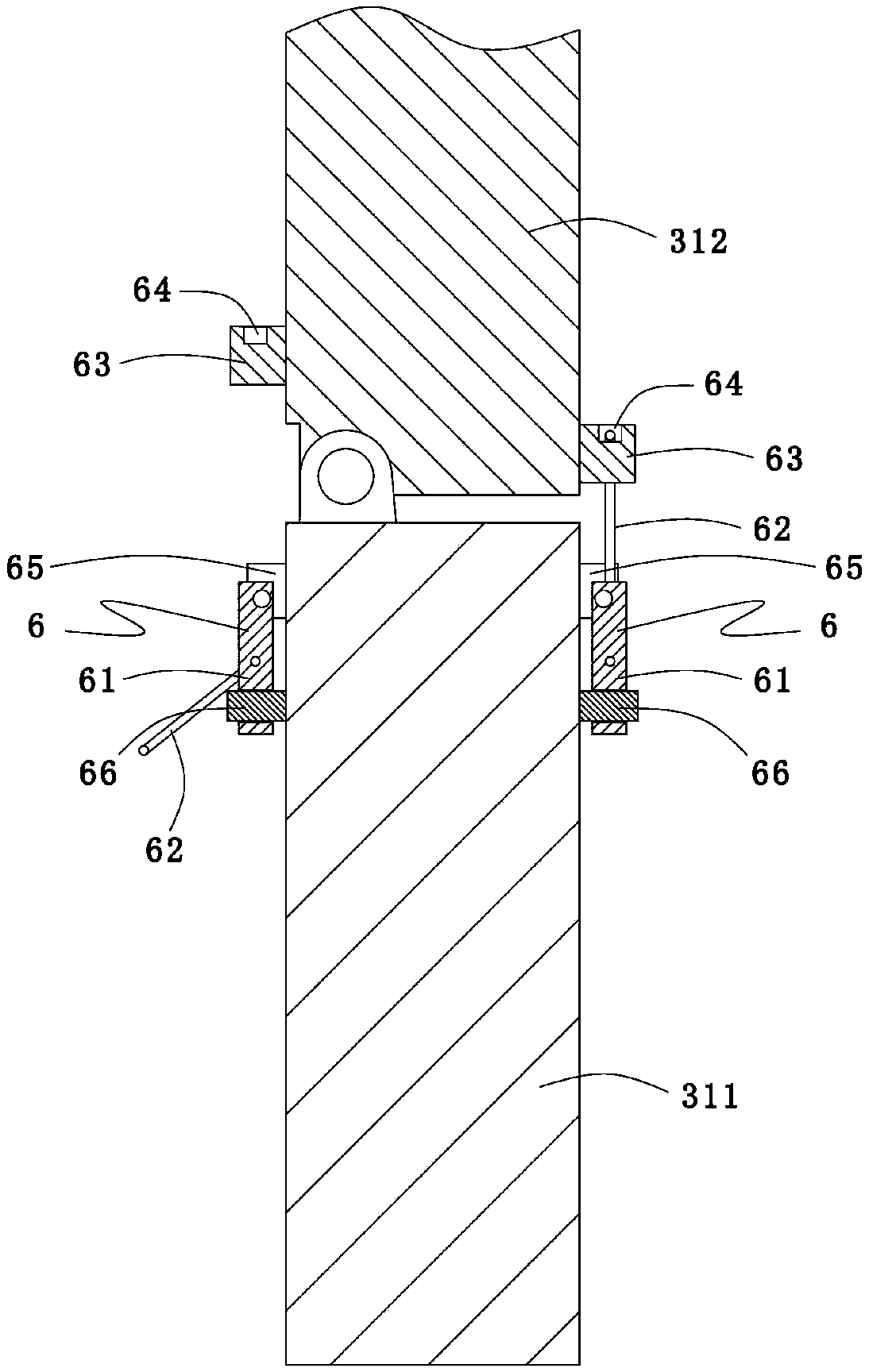

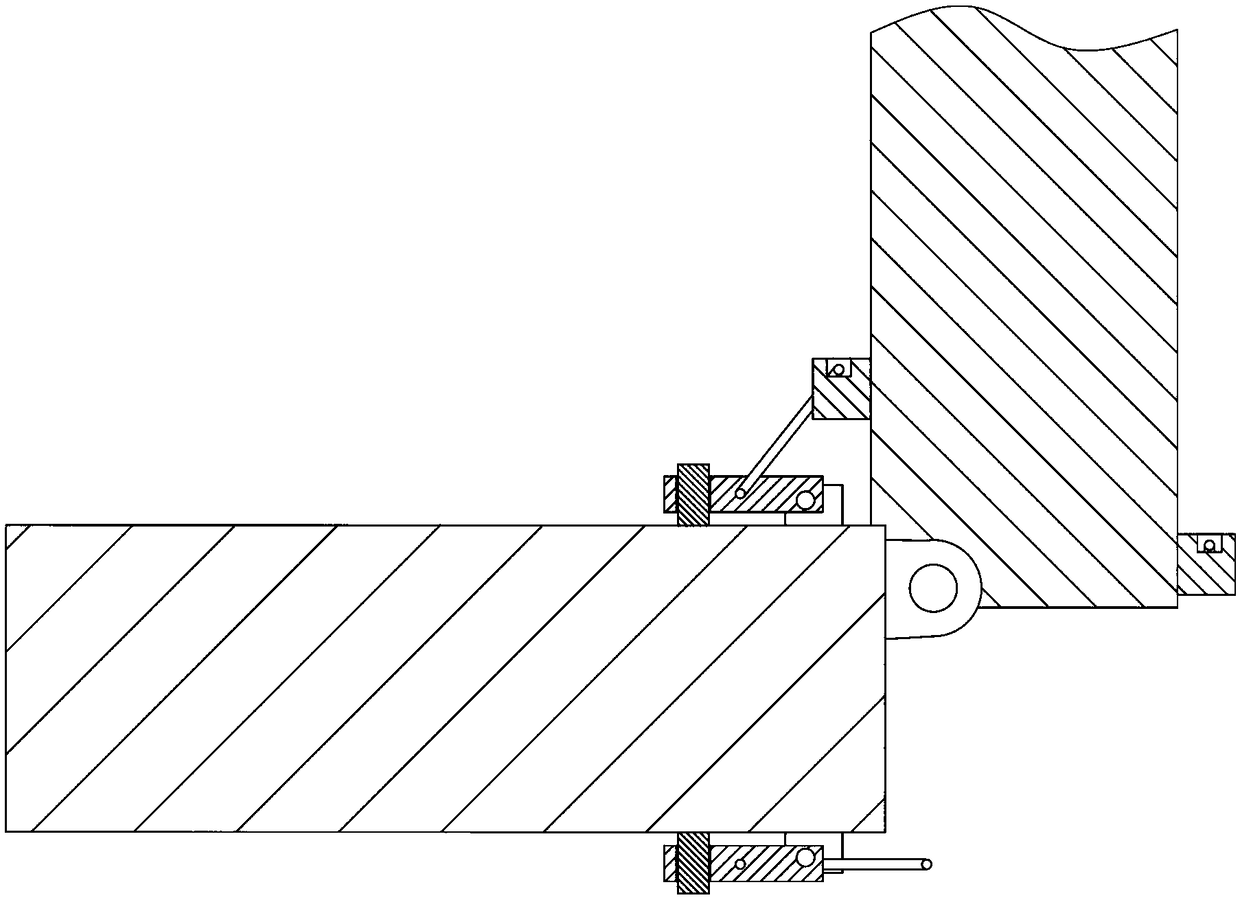

[0018] Such as Figure 1-5 As shown, an ink processing device includes a base 1, a stirring chamber 2 and a stirring member 3, the base 1 is a metal plate, and the stirring chamber 2 is a metal barrel; There is a clamping part 21, which is a ring of metal rings arranged at the bottom of the mixing chamber 2, and a clamping groove 211 is arranged on the clamping part 21, and the clamping groove 211 is formed by clamping The upper end surface of the solid part 21 is a concave ring formed by downward depression; a placement cavity 10 is provided on the base 1, and the stirring chamber 2 is placed in the placement cavity 10; on the side of the placement cavity 10 A movable openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com