Semi-continuous casting device for long slabs of large-scale magnesium alloys

A magnesium alloy, large-scale technology, applied in the field of magnesium alloy casting, can solve problems such as cold cracking and hot cracking, achieve the effects of reducing cracking tendency, reducing temperature gradient, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

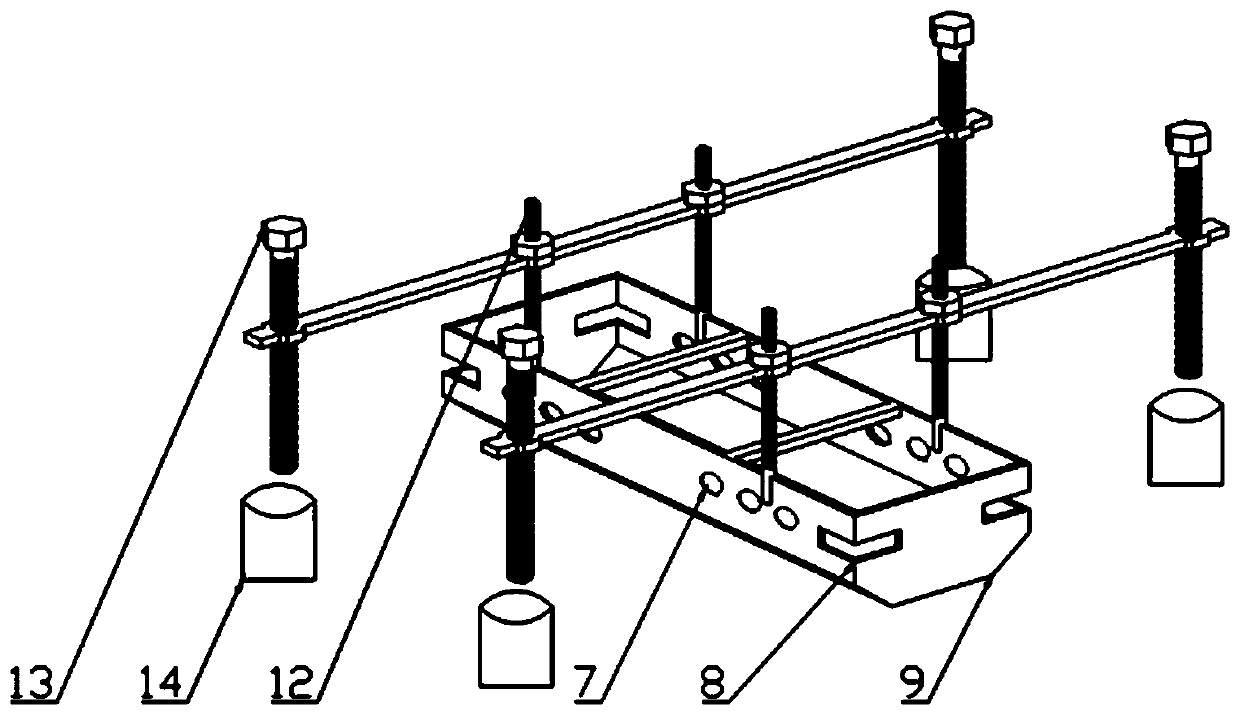

[0049] The structure of the semi-continuous casting device for long slabs of large-size magnesium alloys is as follows: figure 1 As shown, it includes a diverter plate, a crystallizer and a dummy head 6; the crystallizer includes a mold inner sleeve 26, an electromagnetic coil 5, a cold water tank 31 and an oil cover plate 24, and a gas protection nozzle 3 is arranged above the oil cover plate 24 , the crystallizer inner sleeve 26 is provided outside, the electromagnetic coil 5 is located between a cold water tank 31 and the crystallizer inner sleeve 26; the top of the crystallizer inner sleeve 26 is a shunt plate, and the lower part of the crystallizer inner sleeve 26 is a dummy head 6;

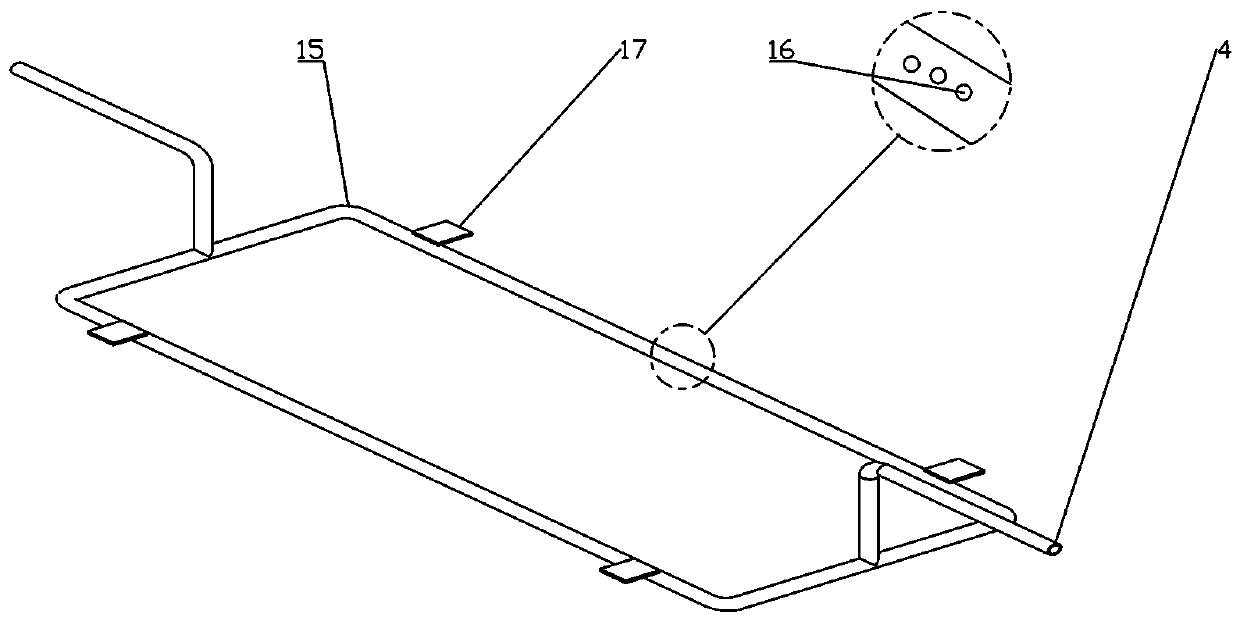

[0050] The diverter plate is a single diverter plate 1, such as figure 2 As shown, a height adjustment device is arranged above the diverter plate, and the height adjustment device is composed of a height adjustment screw fixing base 14, a height adjustment screw 13 and a diverter plate sup...

Embodiment 2

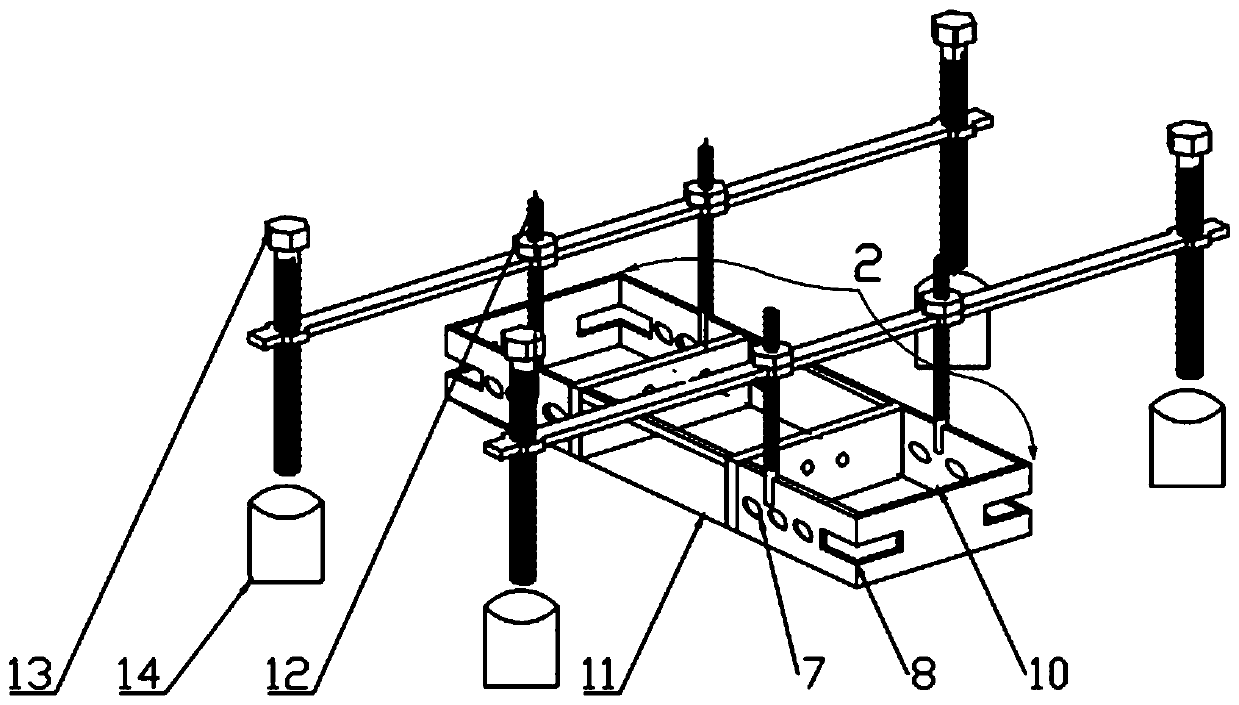

[0065] Device structure is the same as embodiment 1, and difference is:

[0066] The diverter plate is split type diverter plate 2, the structure is as follows image 3 As shown, the split type diverter plate 2 is fixedly connected together by two square grooves 10 through a fixed support base plate 11, and the tops of each square groove 10 are fixedly connected together by connecting rods. The part of the corner is provided with a rectangular shunt opening 8, and a circular shunt hole 7 is arranged on the side wall of the square groove 10; several small holes are arranged on the side wall adjacent to one square groove and the other square groove;

[0067] The method is the same as in Example 1; the obtained magnesium alloy large-size ingot product has no cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com