Metallic 3D printer

A 3D printer and metal technology, applied in the direction of additive processing, can solve the problems of difficult popularization, high quasi-access, high cost, etc., and achieve the effect of reducing its own weight, simple structure, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

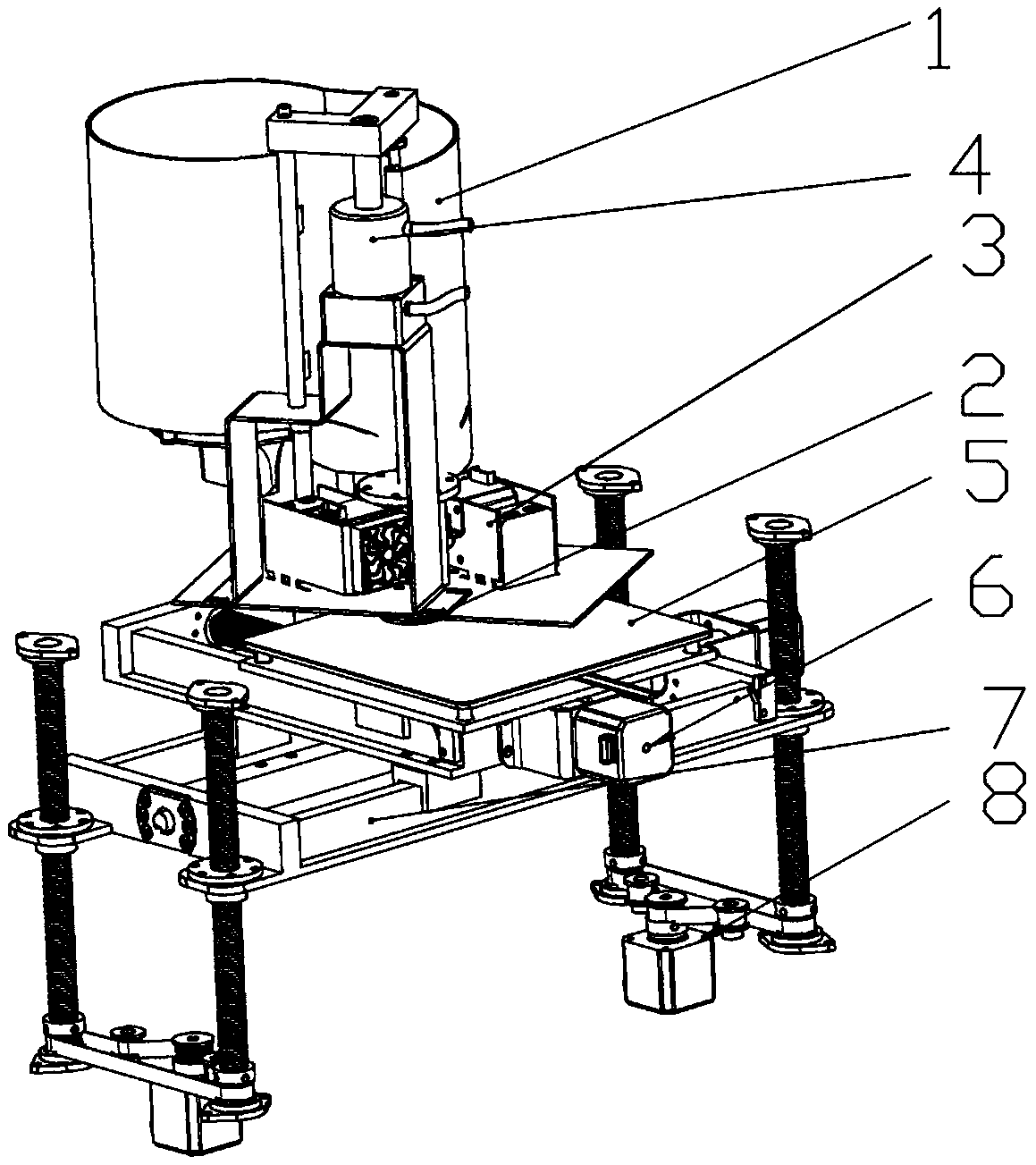

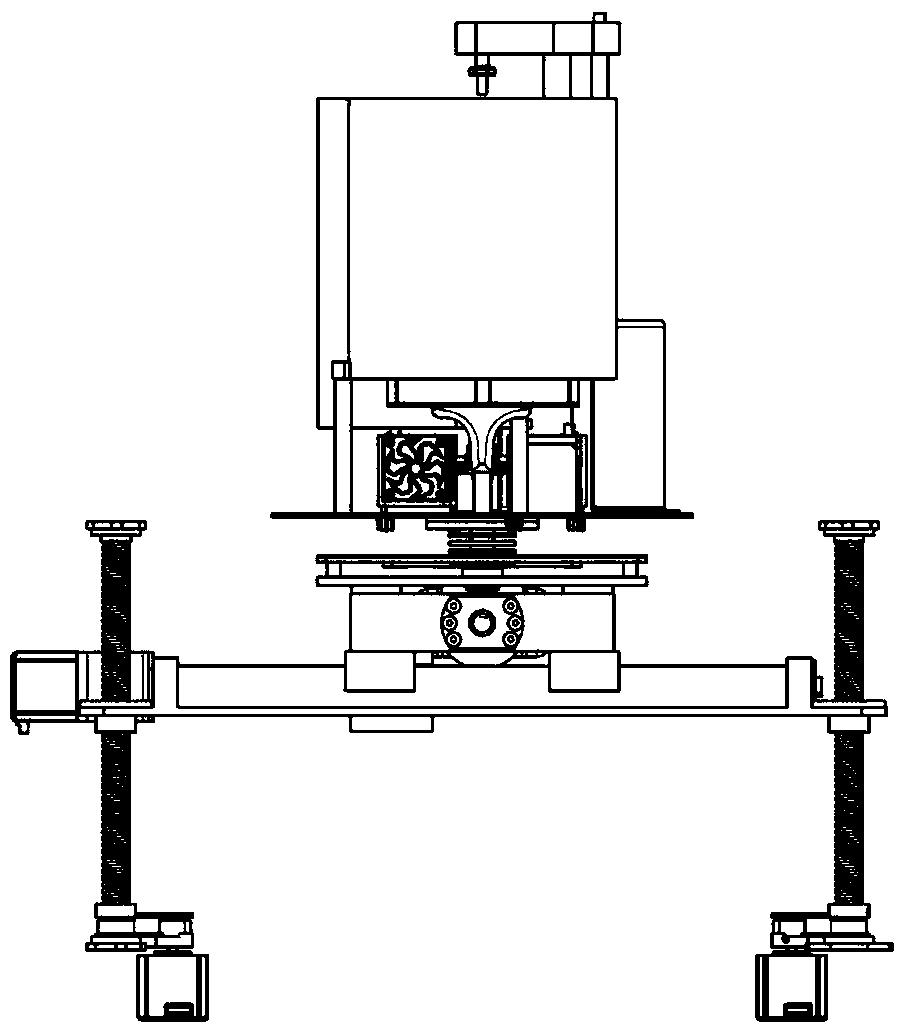

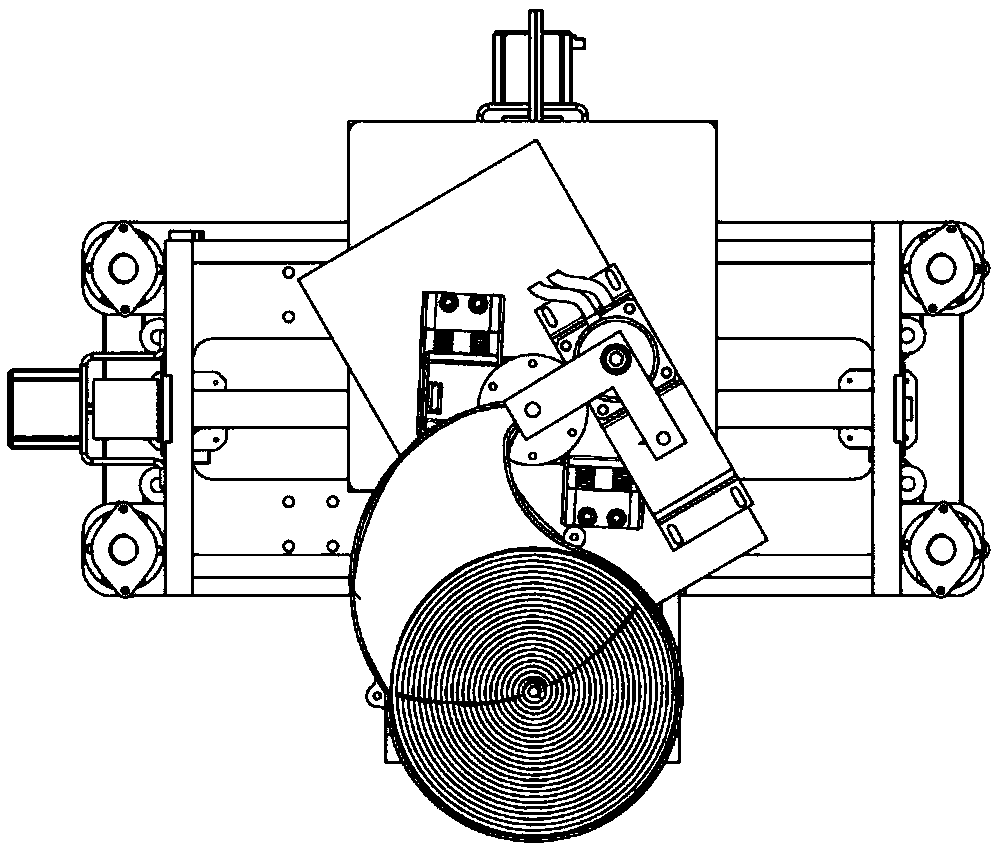

[0030] Such as figure 1 As shown in the three-dimensional structure diagram of a metal 3D printer, a metal 3D printer includes a charging assembly 1, a printing head assembly 2 is installed on the lower side of the charging assembly 1, and an extruder assembly 3 is arranged on the printing head 2 , the extruder assembly 3 cylinder assembly 4, the charging assembly 1 print head assembly 2 extruder assembly 3 cylinder assembly 4 runs through the connecting wire material rod 11, the print head assembly 2 is placed under the printing platform assembly 5, the The printing platform assembly 5 is installed on the Y-axis assembly 6 , the Y-axis assembly 6 is installed on the X-axis assembly 7 , and the X-axis assembly 7 is installed on the Z-axis assembly 8 .

[0031] Such as Figure 4 A material barrel 9 is installed in the charging assembly 1, a coil spring power assembly 12 is arranged under the material barrel 9, a coil spring knob 11 is connected under the coil spring shaft 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com