C-shaped servo welding tongs assembly of power-assisted manipulator

A technology for assisting manipulators and welding tongs, applied in welding equipment, resistance welding equipment, resistance electrode bases, etc., can solve the problems of upper and lower electrode centering deviation, reduce welding firmness, etc., to solve the centering deviation, simple structure, avoid Dangerous effect of flipping the welding tongs too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

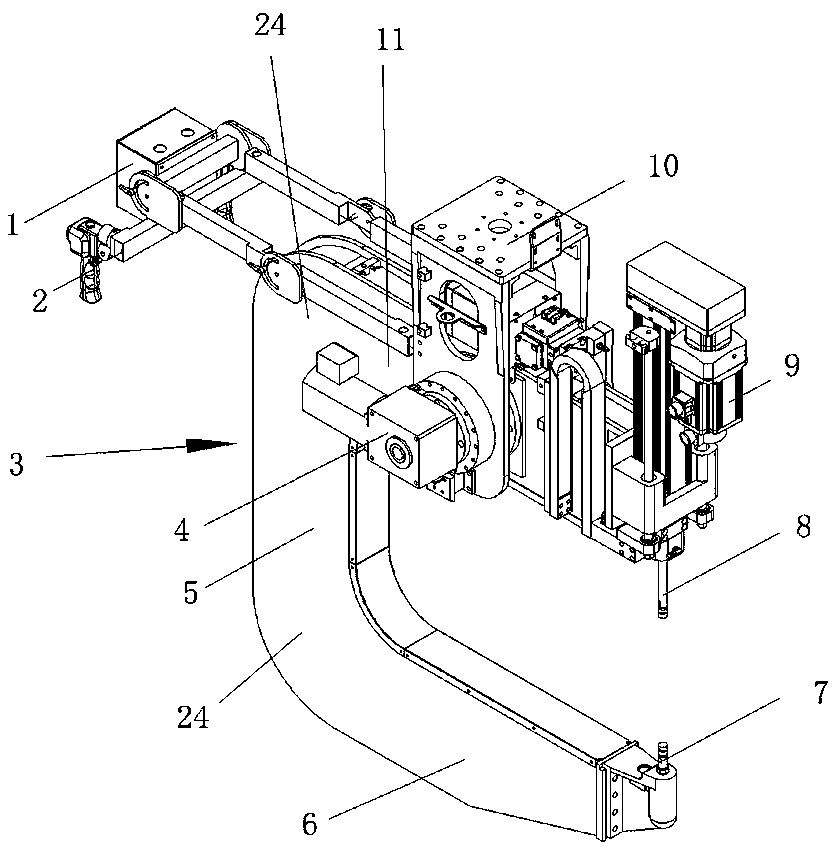

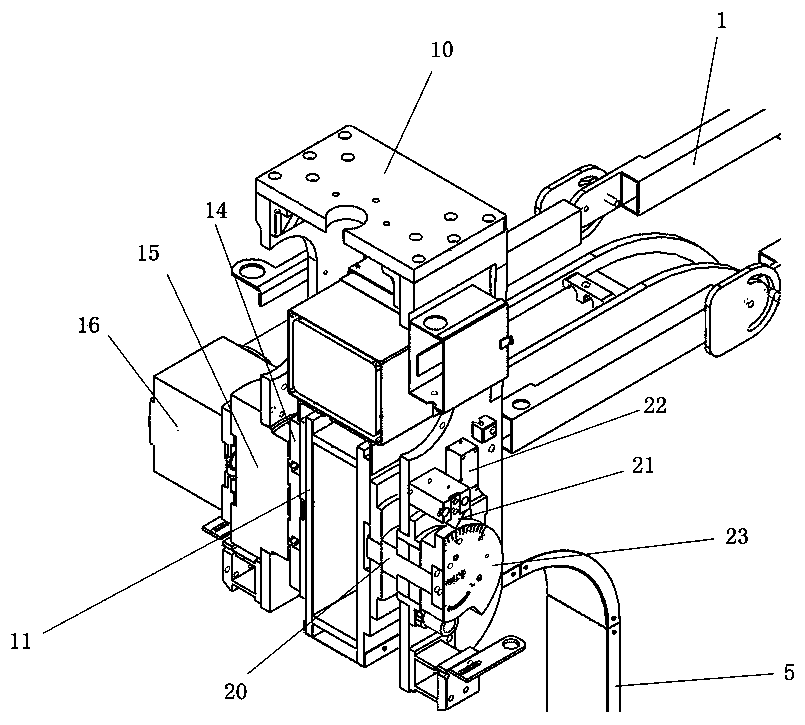

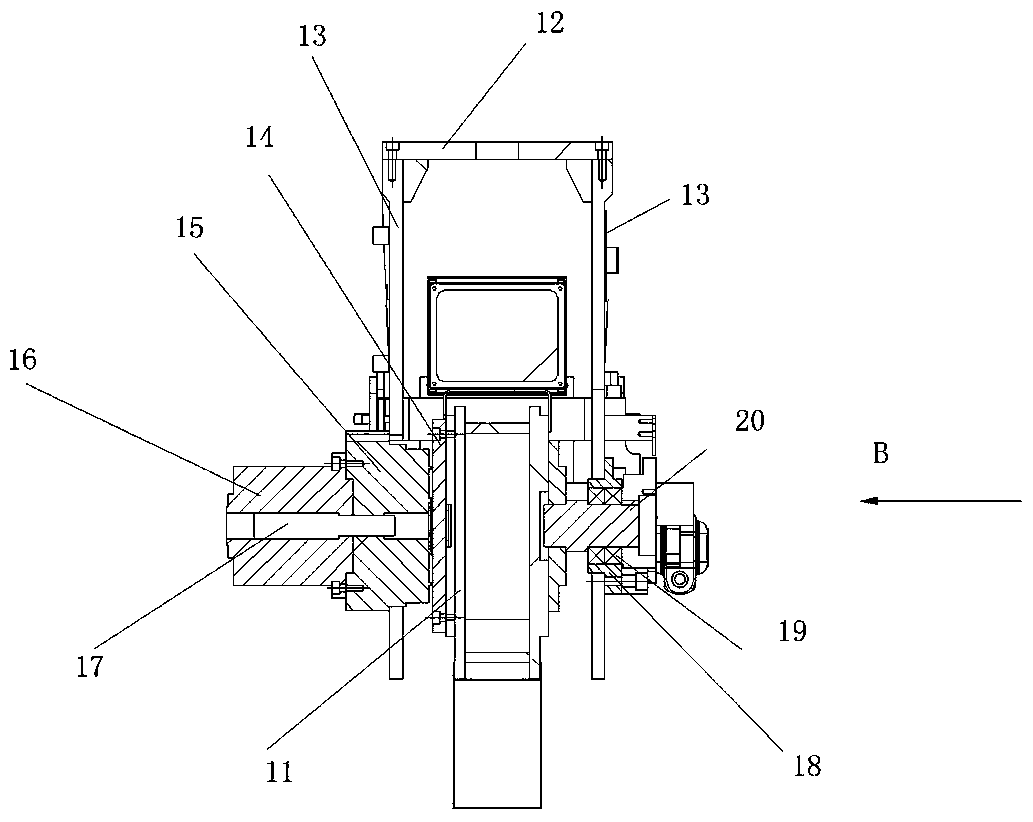

[0019] Such as figure 1 As shown, a C-shaped servo welding tongs assembly of a power-assisted manipulator includes a C-shaped tongs body 3. The tongs body 3 is made of 7075 aviation aluminum for lightweight design and has a throat depth of 900 mm. The pliers body 3 includes an upper pliers body 11 , a lower pliers body 6 and a connecting body 5 , and the upper and lower pliers bodies are connected through the connecting body 5 . An upper electrode 8 is installed on the upper clamp body 11 , and a lower electrode 7 is installed on the lower clamp body 6 . A servo press-down mechanism 9 is installed above the upper electrode 6 , and the downward extension of the upper electrode 8 is realized through the servo press-down mechanism 9 . An operating mechanism 1 is connected to the rear of the upper jaw body 11 , and an operating handle 2 is connected to the operating mechanism 1 . A U-shaped connecting bracket 10 is fixed in the middle of the upper pliers body 1 . The upper plie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com