Feeding device for plate splicing welding

A technology of plate and jacking devices, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of time-consuming and labor-consuming, low welding seam adjustment accuracy, low efficiency, etc., so as to save the time of manual adjustment , Improve welding efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

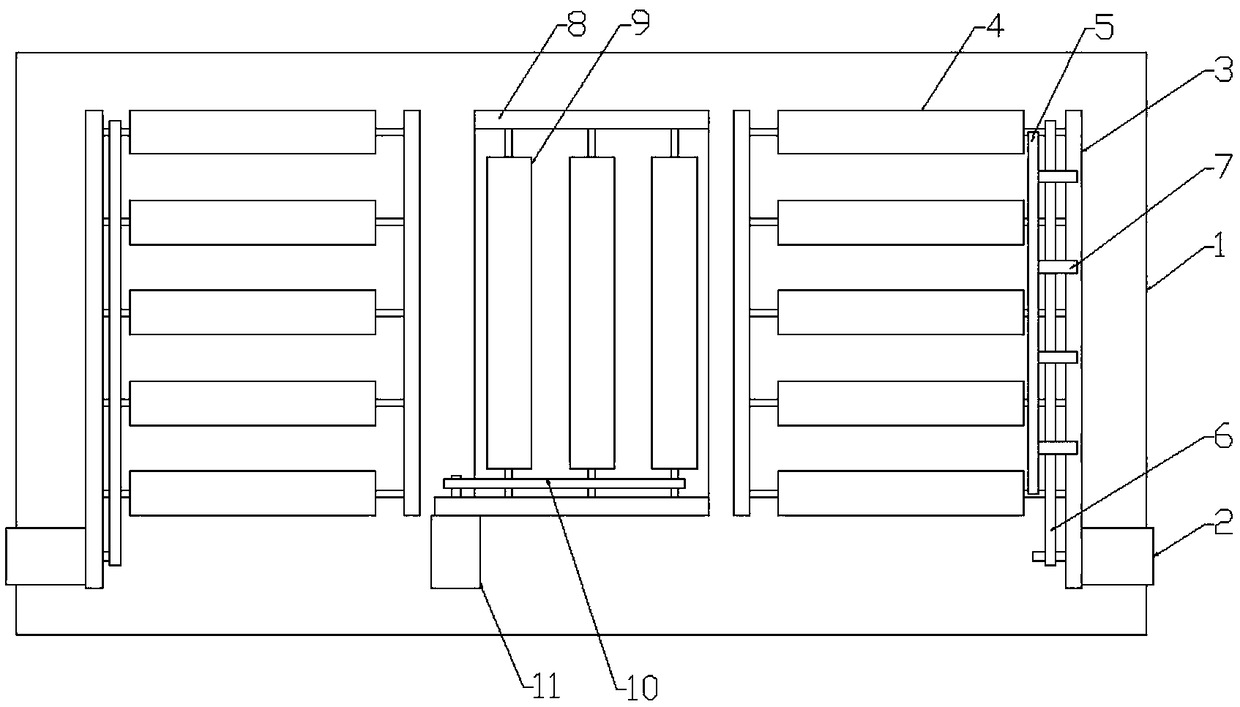

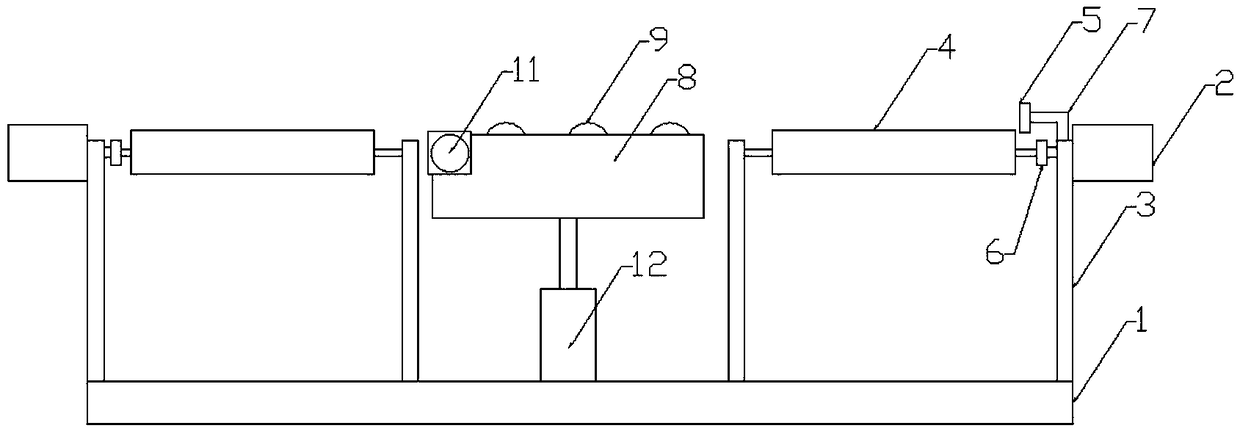

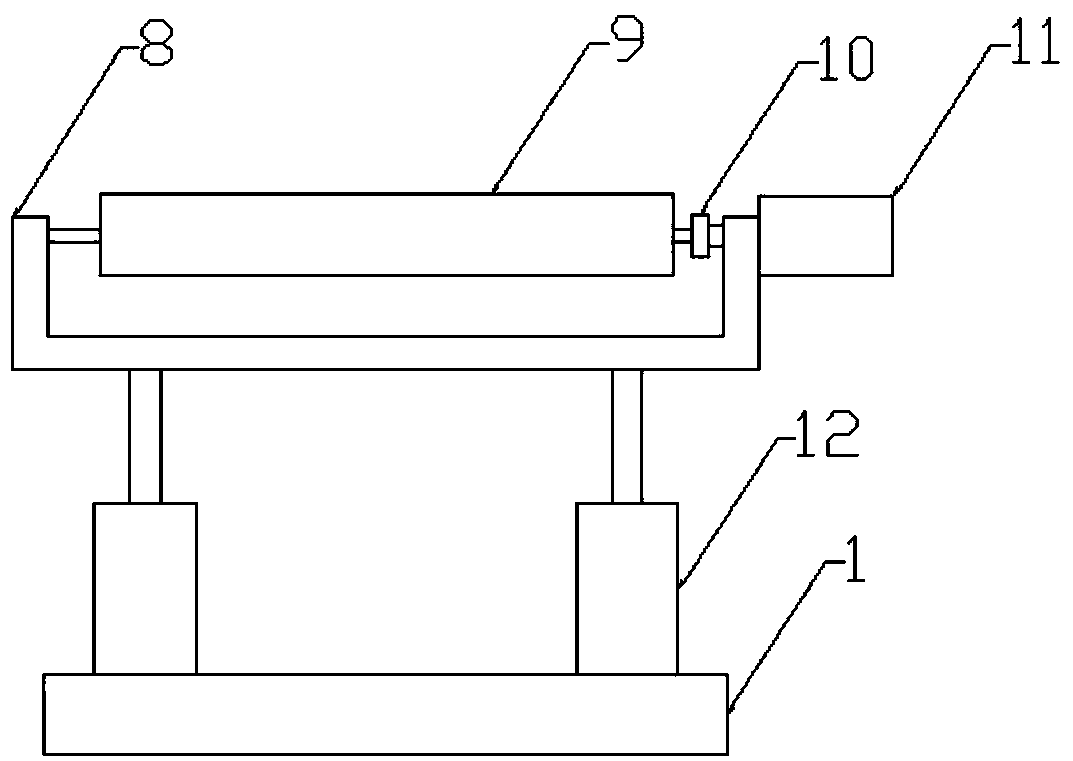

[0013] Figure 1-3 A specific embodiment of the present invention is shown: a feeding device for plate splicing welding, including a base 1, a bracket-3 is provided at both ends of the base 1, and a roller-4 is provided between the brackets-3, so that The side of described support one 3 is fixed with motor one 2, and described motor one 2 is connected with roller one 4 by transmission belt one 6, and described support one 3 side upper end is provided with L frame 7, and the front end of described L frame 7 is provided with Limiting plate 5, said limiting plate 5 is perpendicular to roller one 4, said base 1 middle part is provided with jacking device 12, said jacking device 12 upper end is provided with support two 8 that lifts up and down, said support two 8 is provided with roller 2 9, and the side of described bracket 2 8 is fixed with motor 2 11, and described motor 2 11 is connected with roller 2 9 through transmission belt 2 10, and described roller 2 9 and roller 1 4 mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com