Double-unwinding and double-winding six-color printer and printing method thereof

A technology for printing presses and printing rollers, applied in printing presses, rotary printing presses, general parts of printing machinery, etc., can solve the problems of low utilization rate and low production efficiency of six-color printing presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the present embodiment takes the technical solution as the premise, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

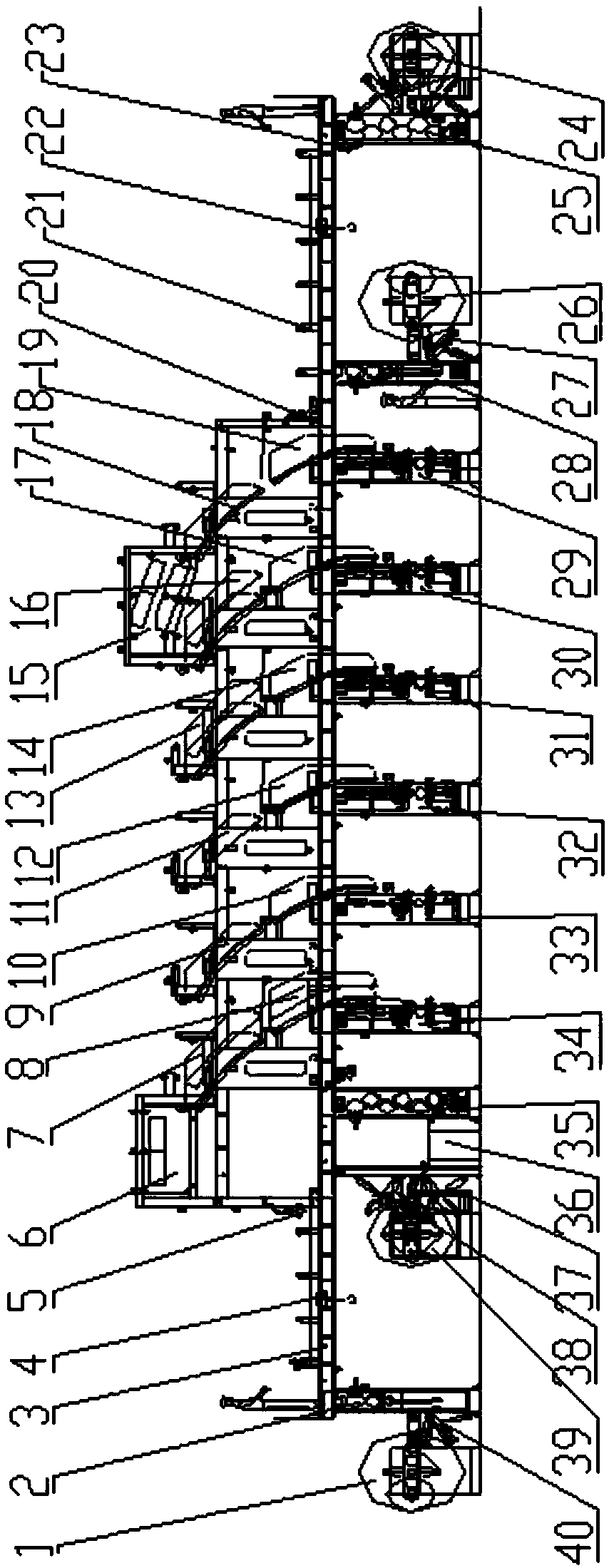

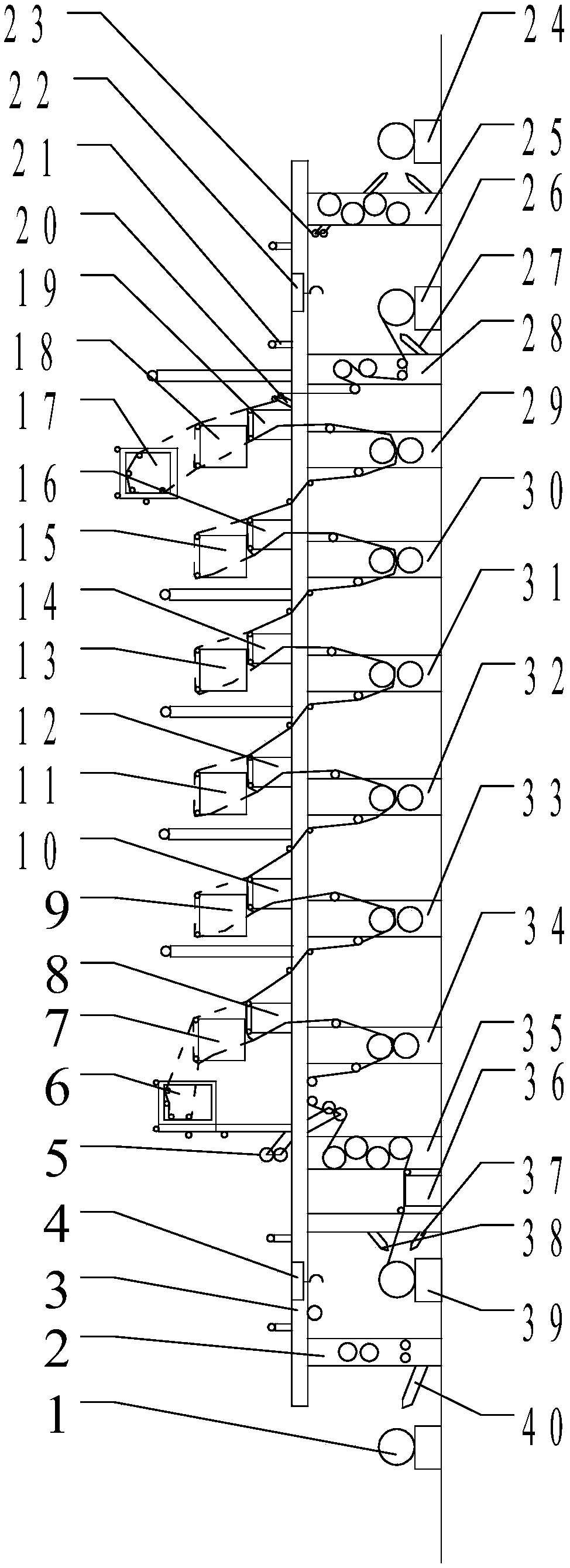

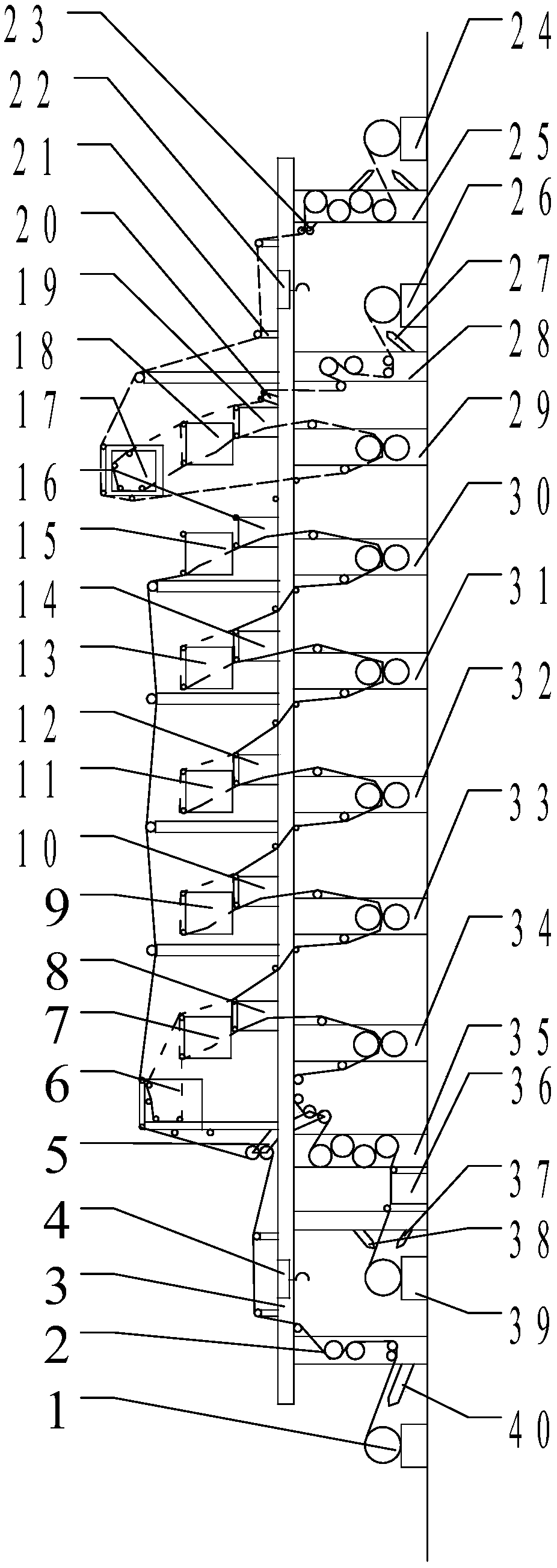

[0030] figure 1 It is a schematic structural diagram of an embodiment of a double-release and double-receive six-color printing machine according to the present invention. A double-release and double-receive six-color printing press includes a frame 3 . One end of the frame 3 is provided with a winder one 1 and a unwinder one 39 , and the unwinder one 39 is located inside the winder one 1 . The frame 3 is provided with a crane one 4, the crane one 4 is slidably connected with the frame 3, the crane one 4 is located between the unwinder one 39 and the winder one 1, and the crane one 4 is the unwinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap