Automatic glaze applying line for ceramic body

A ceramic body and automatic technology, which is applied in the field of ceramic body glazing equipment, can solve problems such as the inability to guarantee uniform glaze, poor product quality, and unreasonable structure, and achieve the effects of perfect functions, guaranteed product quality, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

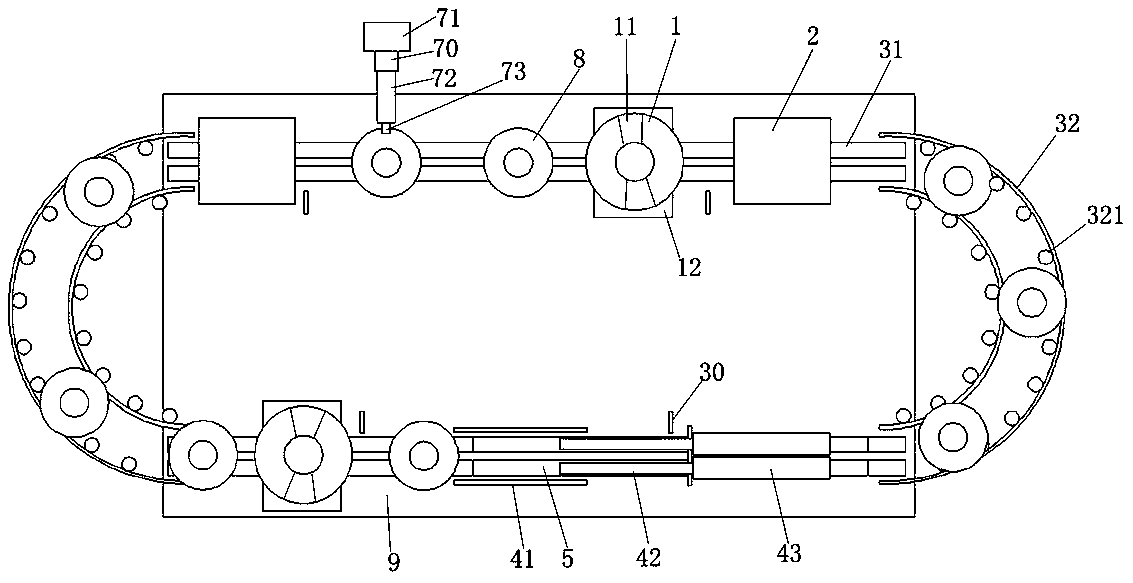

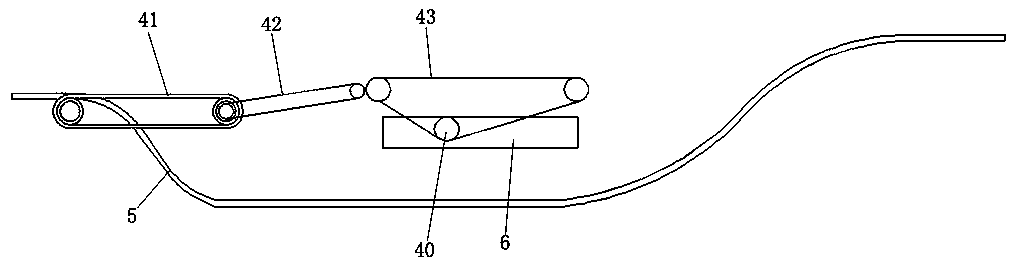

[0018] see figure 1 , figure 2 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention. The present invention is an automatic glazing line for a ceramic body, which mainly includes a glazing table 1, an oven 2 and a conveyor belt. The conveyor belt is in the shape of a runway. Transport a number of bases 8 on the top for transporting green bodies. There is a partially sinking and V-shaped base separation channel 5 in the conveyor belt, and a ceramic blank conveyor belt that is horizontally connected to the conveyor belt is provided above the base separation channel 5. The ceramic blanks The conveyor belt is used to separate the base 8 from the green body, and the green body is transported separately for discharge. There is also a green body turning mechanism on the conveyor belt, and a group of glazing tables 1, ovens 2, The body is firstly heated, and then enters the glazing table 1 for glazing, and then is turned over by the body t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com