Construction method suitable for deep foundation pit support structure large in excavation area

A deep foundation pit support and construction method technology, applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of inconvenient construction on site, untimely construction support, instability, etc., and achieve shortened construction period, reduced workload, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

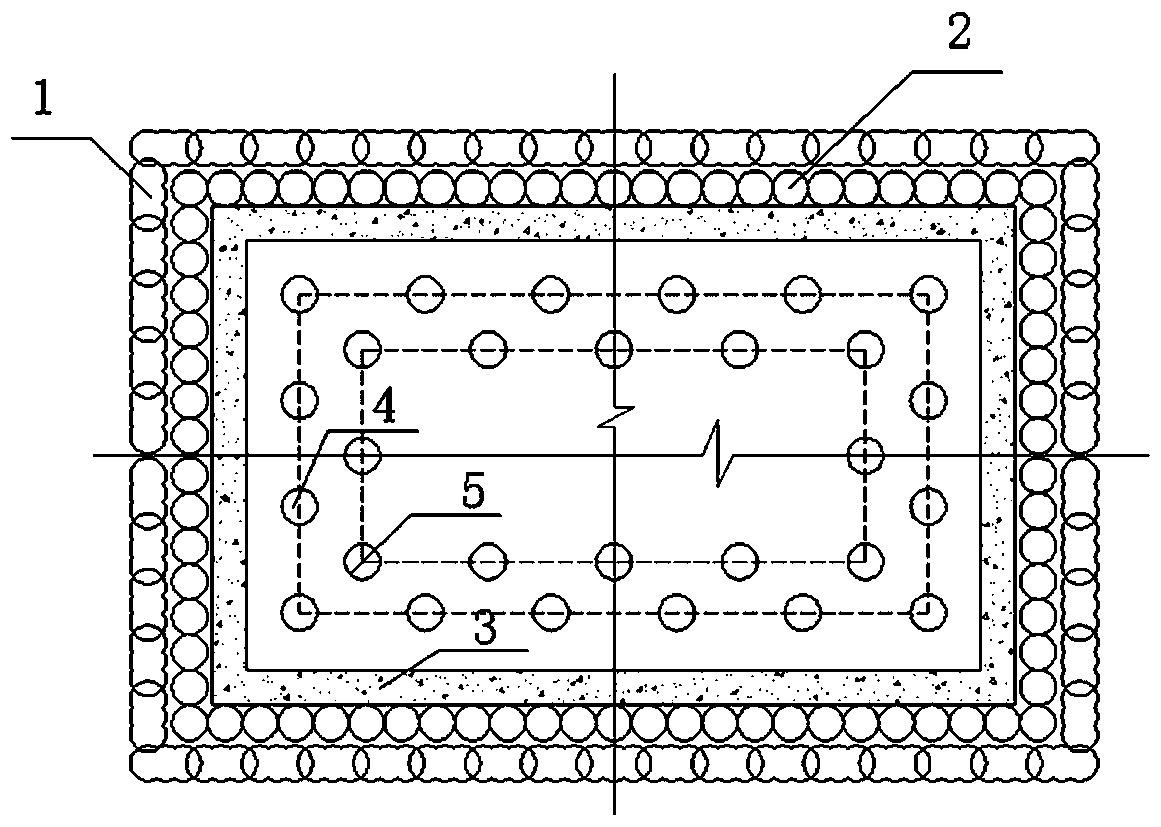

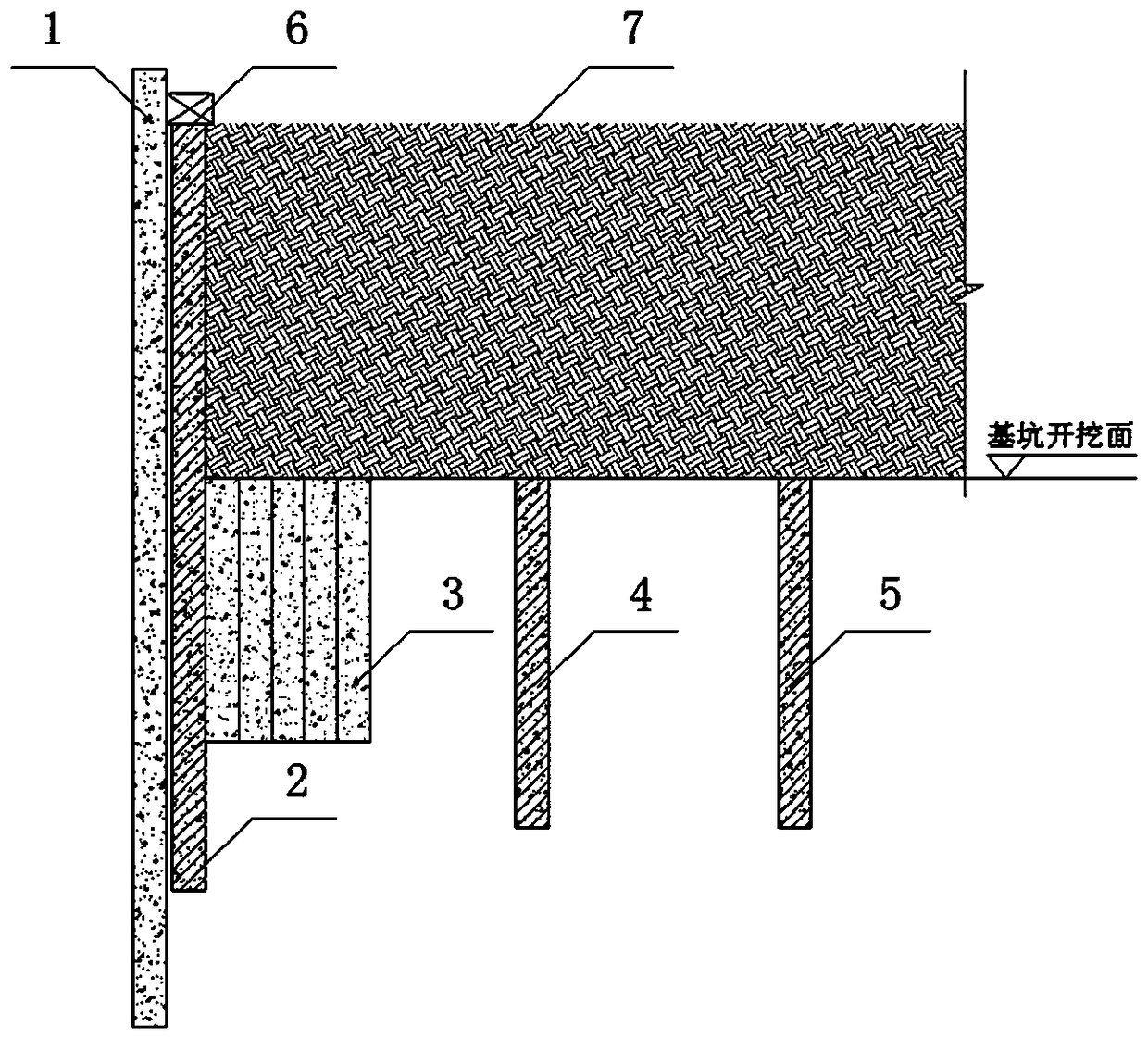

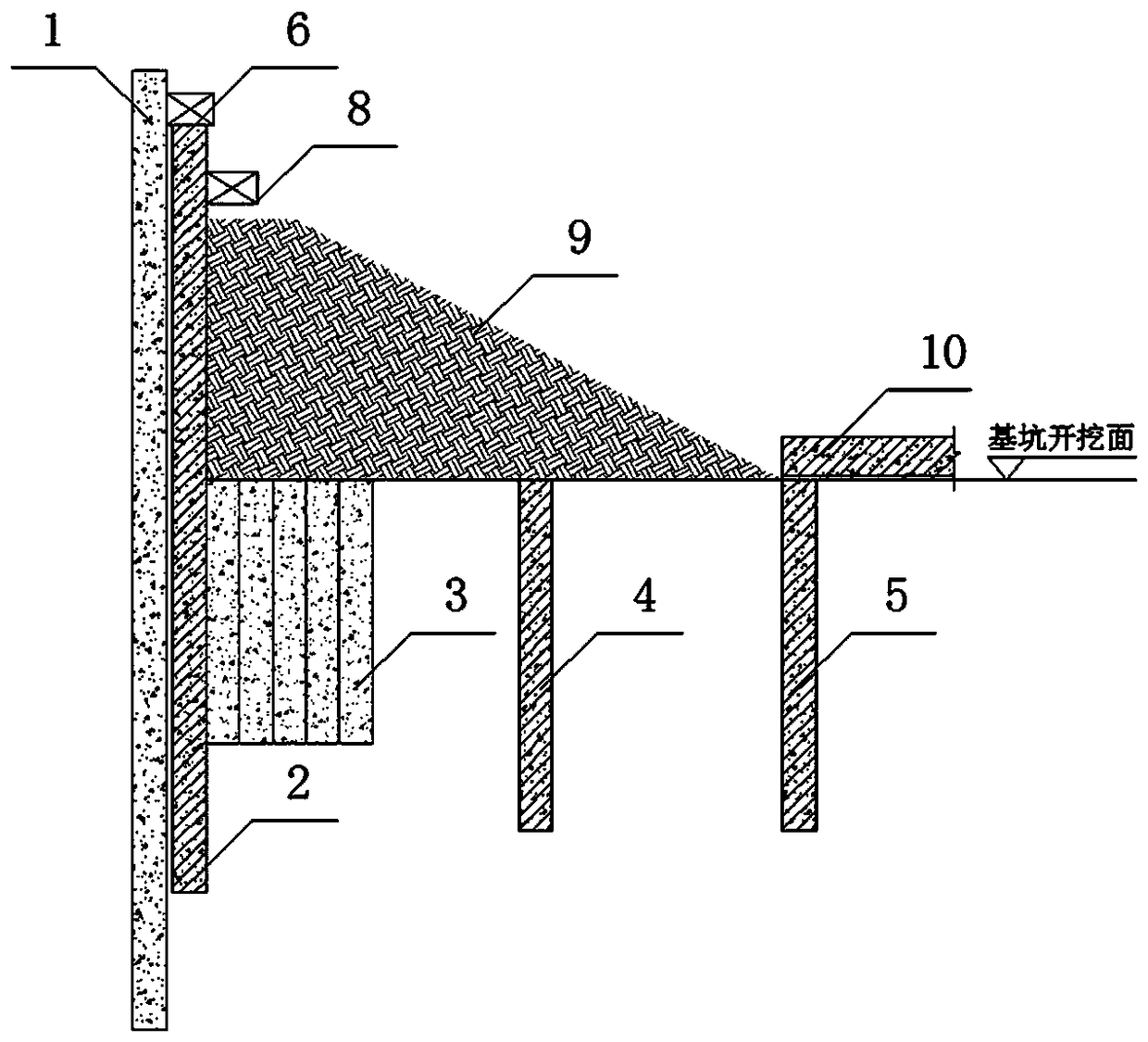

[0054] see figure 1 and figure 2 , a construction method suitable for supporting structures of deep foundation pits with a large excavation area, comprising several second bored piles 4 and several third bored piles 5, the second bored piles 4 and The third bored pile 5 is constructed in the foundation pit, the second bored pile 4 forms an outer circle, the third bored pile 5 forms an inner circle, and the second bored pile 4 serves as the second inclined steel pipe support 15 is at the fulcrum of the raft foundation, and the third bored pile 5 is used as the first inclined steel pipe support 11 at the fulcrum of the raft foundation.

[0055] The construction of the second bored pile 4 and the third bored pile 5 is completed together with the enclosure structure, and the elevation of the pile top is controlled at the excavation surface of the foundation pit. After the excavation of the earthwork is completed, the first raft foundation 10 and the The second raft foundation 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com