In-vein filling mining method

A filling mining method and mine house technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of high development ratio of 10,000 tons, insufficient mine room, simultaneous mining of layer veins cannot meet the use requirements, etc., and achieve change of production capacity If it is too low, the effect of improving the ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

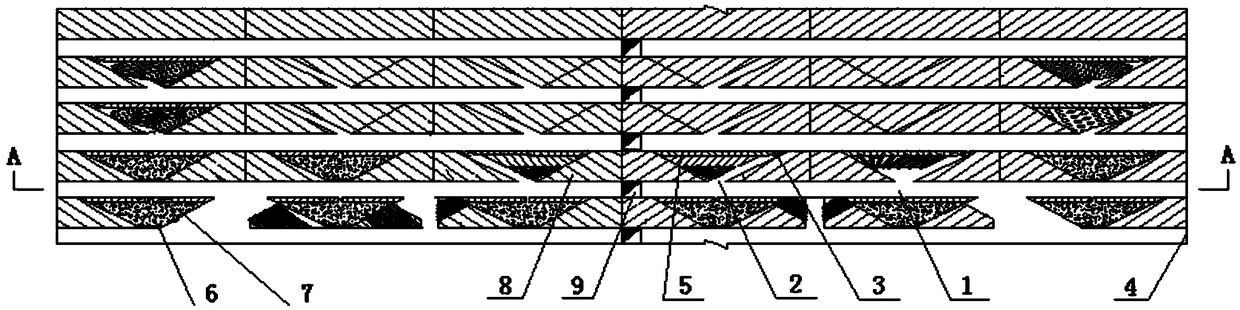

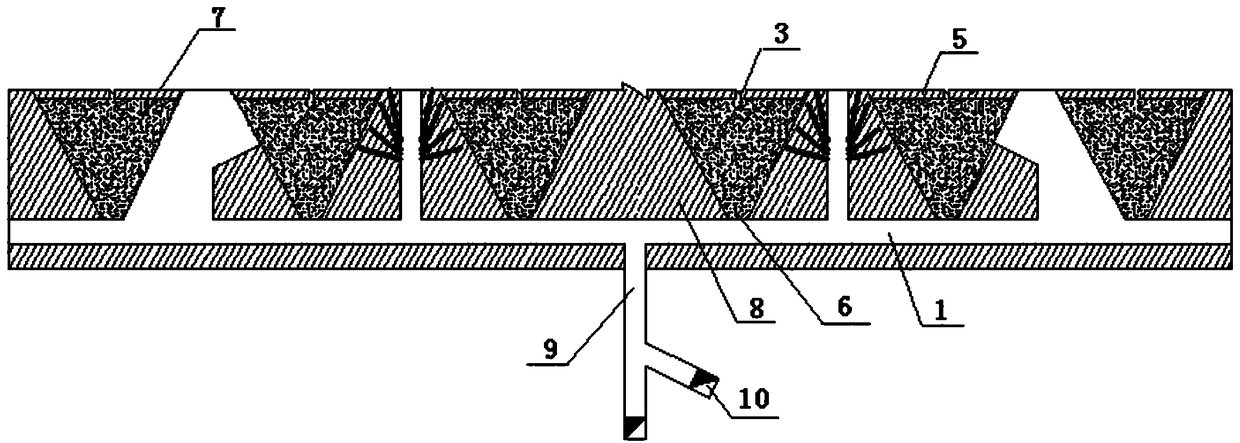

[0024] Such as Figure 1-2 Shown, a kind of vein filling mining method, comprises the following steps:

[0025] Step 1: Excavate level roadway 1 in multiple layered excavations in the panel system, and pull cutting grooves obliquely in the direction of the upper layer at intervals of 30-50m as ventilation shafts 2, when the cutting grooves run through the upper layer 2m away , open a hole 3 along the roof to the upper layer, and enter the next step when the excavation reaches the panel boundary 4; when pulling the cutting groove, the two adjacent cutting grooves should be symmetrical to each other, so as to facilitate the formation of "V" shaped empty field 7;

[0026] Step 2: Mining the layered mine house. During the mining process, make a fan-shaped mining around the cutting groove, reserve 2m from the previous layer as the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com