Support disconnected type fixed guide pin split brake for hub motor

A technology of in-wheel motor and guide pin, which is applied to the axial direction of brakes, brake types, brake components, etc., can solve the problems of high production, maintenance and installation costs, inconvenient disassembly and assembly of brakes, etc., to reduce weight and facilitate up and down movement. , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

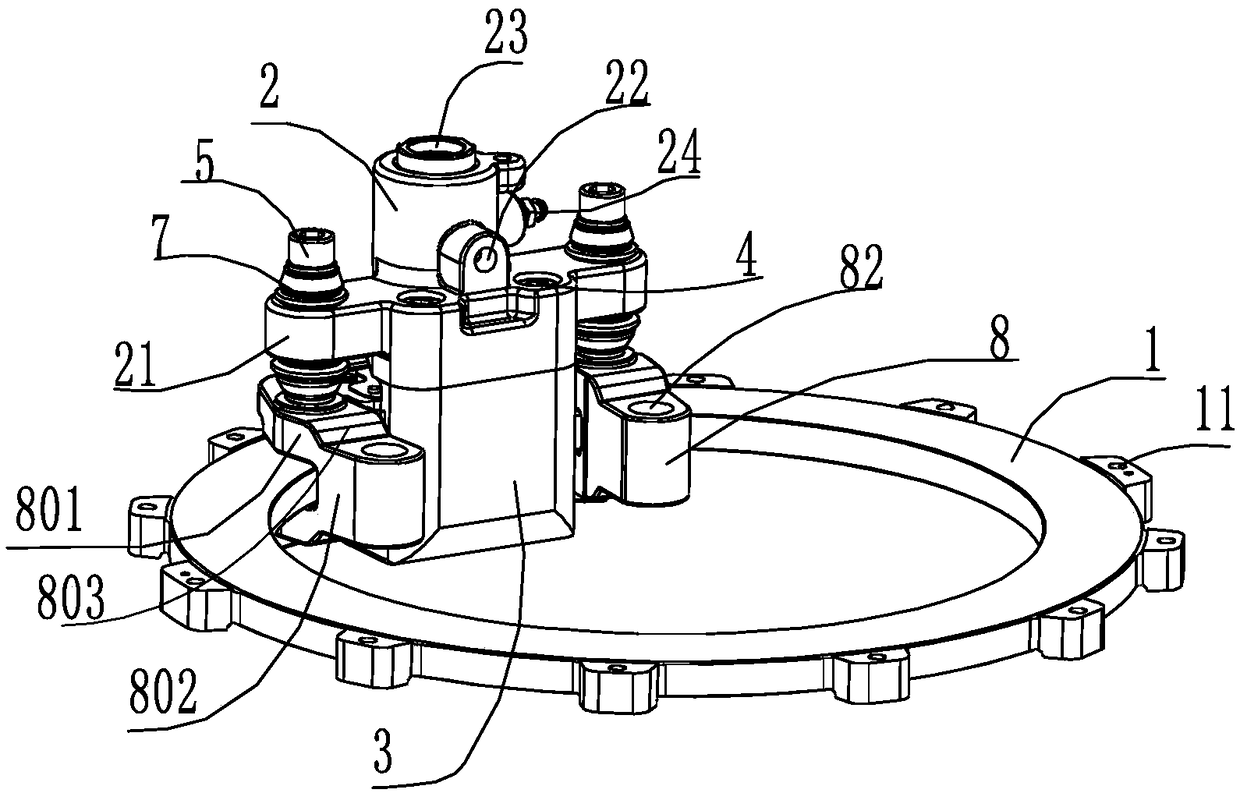

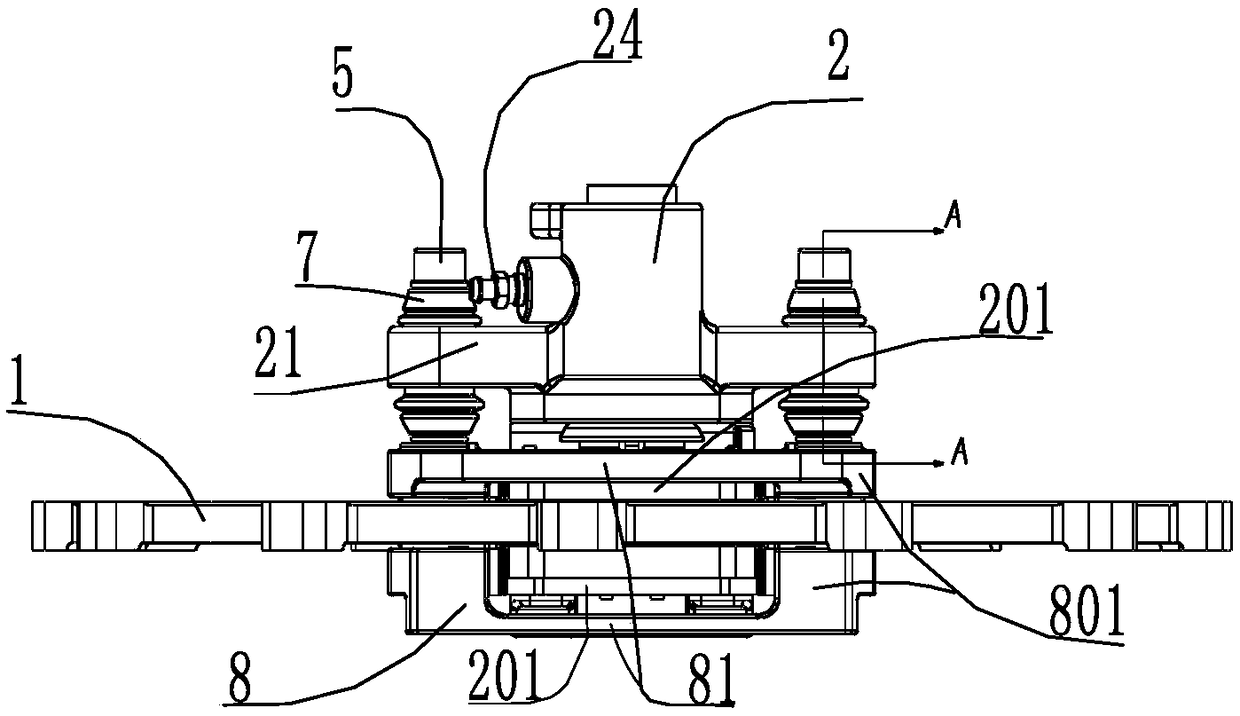

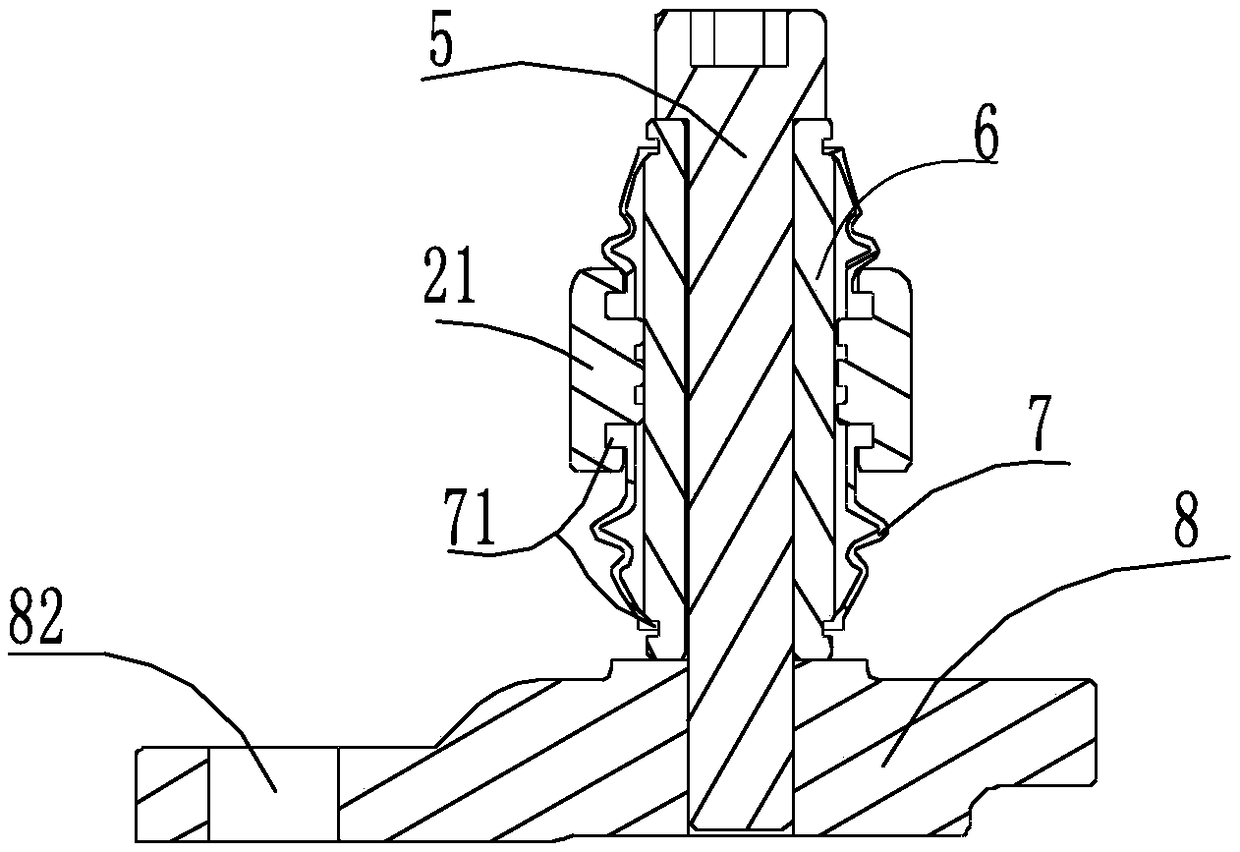

[0027] figure 1 , figure 2 , image 3 and Figure 4 Among them, a bracket disconnected fixed guide pin split brake for hub motors, including a brake disc 1, an upper caliper body 2 and a lower caliper body 3, the upper caliper body 2 and the lower caliper body 3 are respectively located on the brake disc 1 The two sides are relatively fixedly connected, figure 1 Among them, the upper tong body 2 and the lower tong body 3 are provided with corresponding threaded connection holes 4, and the threaded connection holes 4 of the upper tong body 2 and the lower tong body 3 are provided with connecting bolts. The upper caliper body 2 and the lower caliper body 3 are provided with friction plates 201 on the opposite inner surface, and the two sides of the upper caliper body 2 are respectively provided with guide pins 5 perpendicular to the plane wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com