Watch jewel bearing inner hole arc-shaped machining device

A gemstone bearing and processing device technology, used in watches, clocks, repair tools, etc., can solve problems such as damage, inner hole processing deformation, and the accuracy of processing is difficult to meet requirements, so as to improve mobility, improve stability, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

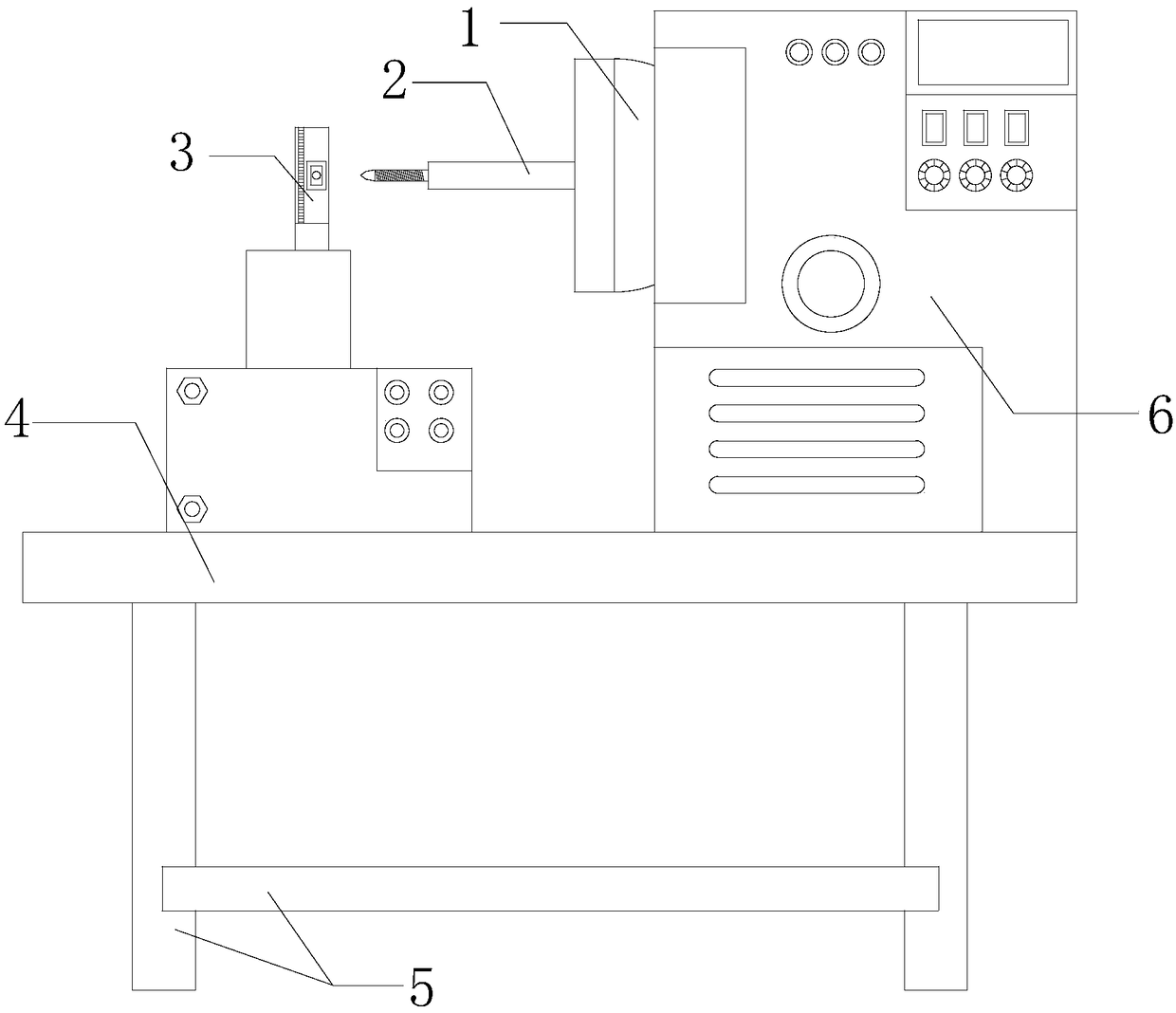

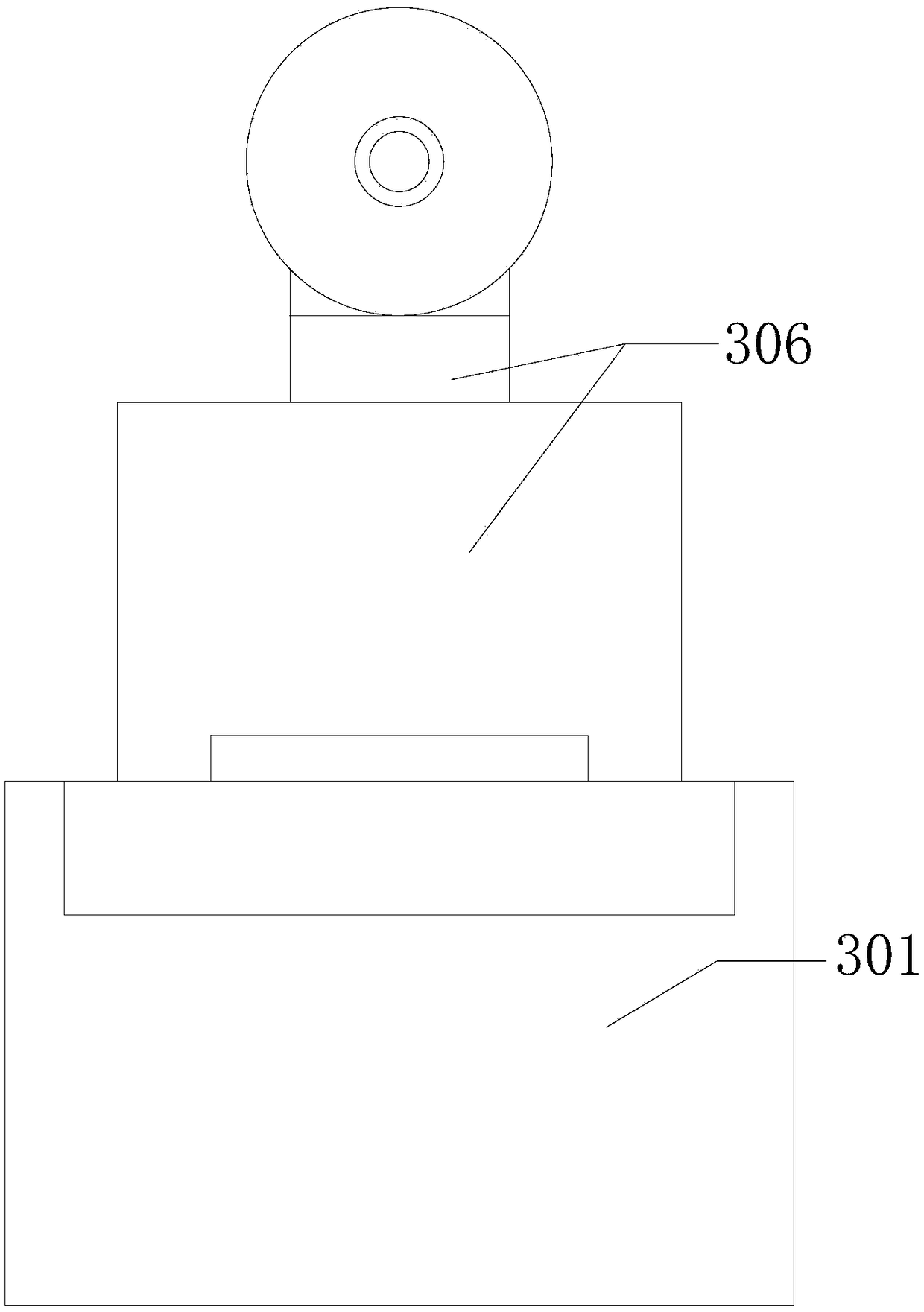

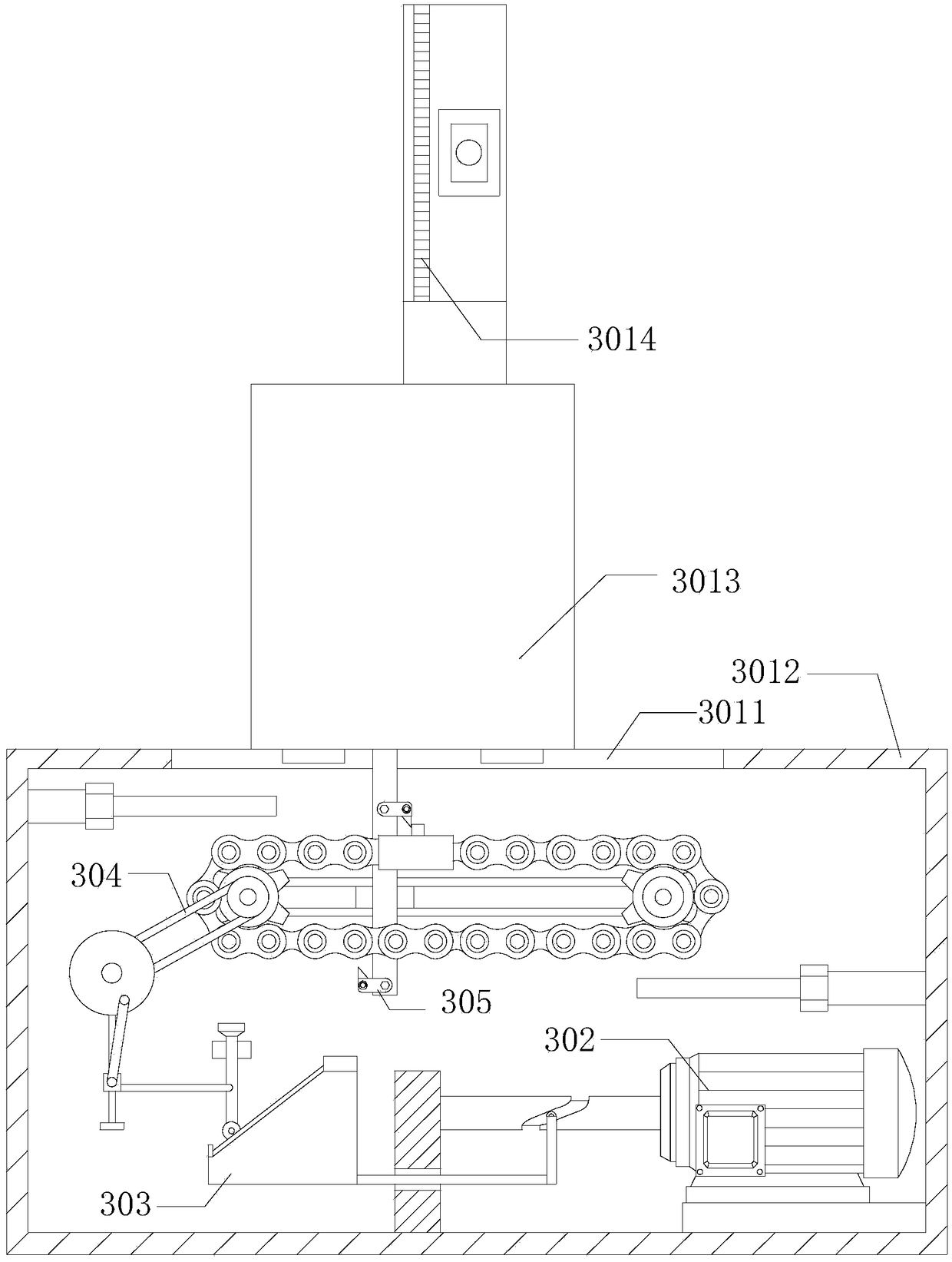

[0025] see Figure 1-Figure 7, the invention provides a watch jewel bearing inner hole arc processing device, a watch jewel bearing inner hole arc processing device, the structure of which includes an adjustment micro-drill seat 1, a micro-drill removal shaft 2, a bearing fixing conversion device 3, an operating table 4, a support The tripod 5, the rotating brake box 6, the micro-drill removal shaft 2 is vertically installed on the micro-drill base 1 for adjustment and the two are fixedly connected together by welding, the bottom of the bearing-fixed conversion device 3 The end is installed together with the upper surface of the console 4 by means of electric welding, the four supporting legs 5 are fixedly welded to the four positions at the bottom of the console 4, and the rotating brake box 6 passes through the console 4 Located on the same level as the console 4, the bearing fixed transformation device 3 includes a supporting component device 301, a motor braking device 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com