Object recognition classification and defect detection method based on machine vision

A technology of recognition classification and defect detection, which is applied in the direction of character and pattern recognition, instruments, computer parts, etc., can solve the problems of not being able to detect defects of different types of items, not being able to use classification and identification of items, and the detection object is limited to cloth, etc., to achieve detection Fast speed, high detection accuracy, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

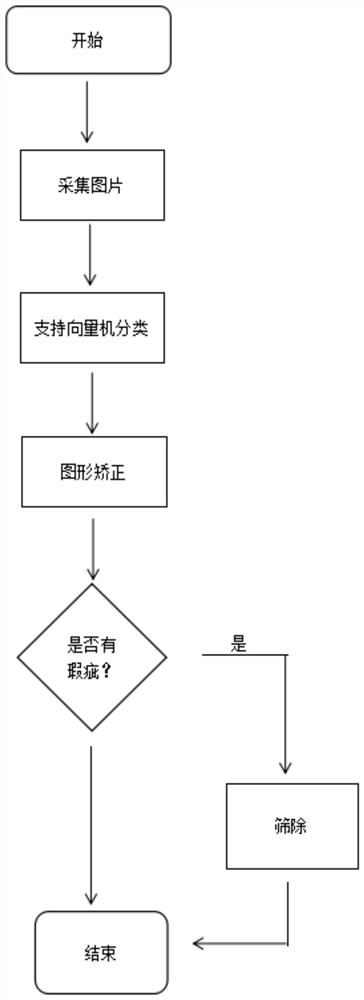

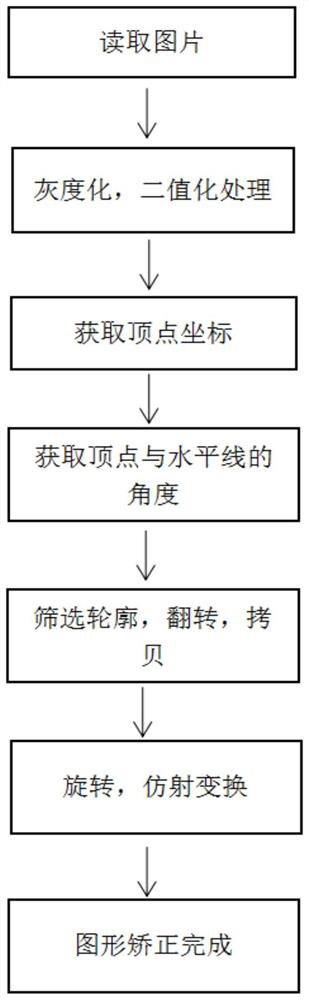

[0034] Such as Figure 1-5 As shown, the machine vision-based item identification and classification and defect detection method of the present invention can be roughly divided into two steps: item type identification and classification and defect detection.

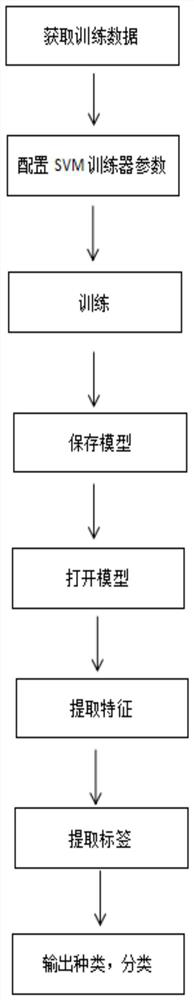

[0035] 1. The process of identifying and classifying items is based on the support vector machine, including the model training process and loading the model to realize the classification process; the training data is obtained through the positive and negative samples prepared in advance, the training is performed after configuring the parameters of the SVM trainer, and the trained model is saved; After opening the trained model, perform feature extraction on the detected pictures, compare the data obtained during training, extract matching labels, output the type of the label, and then perform classification.

[0036] 1. Model training process

[0037] First obtain the training pictures downloaded from the picture data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com