Highway electromechanical operation and maintenance management system and method

An operation and maintenance management, highway technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as fault response time, long fault discovery time, single fault repair method, and difficulty in defining software and hardware problems, reducing management. Time and economic losses, increased maintenance efficiency, increased service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the examples.

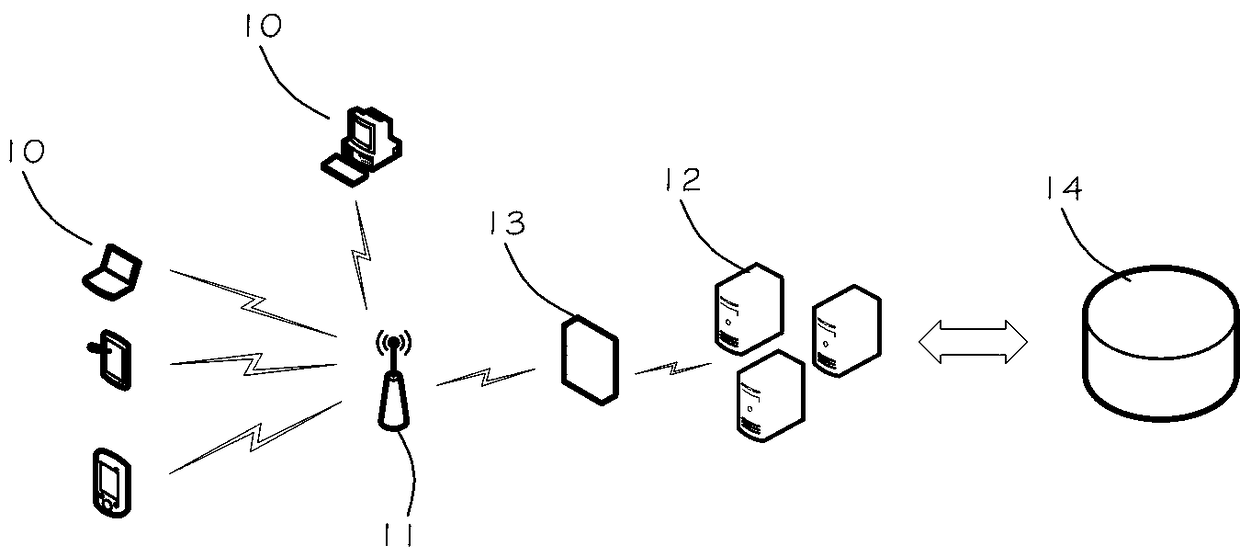

[0038] Such as figure 1 Shown is the structure diagram of the system, the user terminal 10 of the system can be logged in through a mobile device or a computer, and the faulty section or equipment can be repaired by using the mobile device or computer. The physical location information, fault type, fault level, repair quota and inspection man-hours of the equipment can be preset. Then the fault information is transmitted to the application server 12 through the Internet 11, and a firewall 13 is arranged between the Internet 11 and the application server 12, which can effectively prevent internal secrets from leaking out and limit unexpected malicious access. Through the arrangement of the application server 12, the fault information is finally uploaded to the storage unit 14, and the fault information is saved, and the repaired information will also be uploaded to the storage unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com