Corn threshing notch board capable of automatically adjusting grid spacing

A grid spacing and corn threshing technology, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of high corn seed damage rate, unadjustable grid spacing, and uncontrollable adjustment range, so as to avoid entrainment loss , improve the effect, improve the effect of threshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

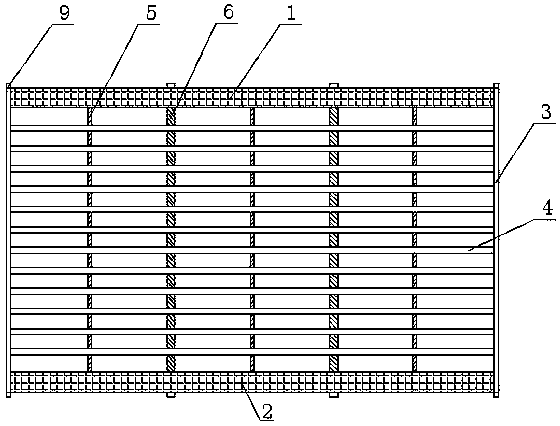

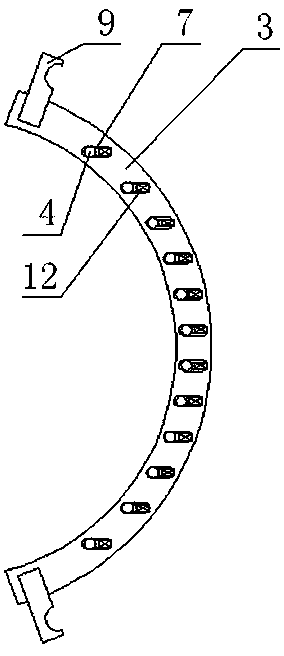

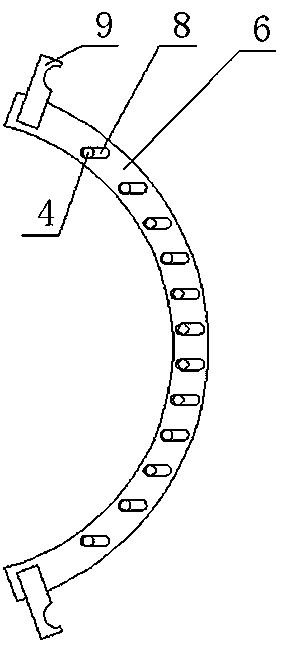

[0034] A corn threshing concave plate capable of automatically adjusting grid spacing, comprising an upper connecting plate 1 and a lower connecting plate 2, the two ends of the upper connecting plate 1 and the lower connecting plate 2 are respectively fixedly connected with side connecting plates 3, and the side connecting plates 3 is an arc-shaped plate, and there are several parallel grid round steel bars 4 movable between the two side connecting plates 3, and several grid round steel bars 4 are uniformly opened on the side connecting plate 3 from top to bottom, corresponding to the grid round steel bars 4 one by one. The first waist-shaped groove 7, the extension direction of the first waist-shaped groove 7 is the same as the normal direction at the midpoint of the side connecting plate 3, and the two ends of the grid round steel 4 are slidingly arranged in the first waist-shaped groove 7 One end of the first waist groove 7 is connected to the grid round steel 4 through a s...

Embodiment 2

[0036]A corn threshing concave plate capable of automatically adjusting grid spacing, comprising an upper connecting plate 1 and a lower connecting plate 2, the two ends of the upper connecting plate 1 and the lower connecting plate 2 are respectively fixedly connected with side connecting plates 3, and the side connecting plates 3 is an arc-shaped plate, and there are several parallel grid round steel bars 4 movable between the two side connecting plates 3, and several grid round steel bars 4 are uniformly opened on the side connecting plate 3 from top to bottom, corresponding to the grid round steel bars 4 one by one. The first waist-shaped groove 7, the extension direction of the first waist-shaped groove 7 is the same as the normal direction at the midpoint of the side connecting plate 3, and the two ends of the grid round steel 4 are slidingly arranged in the first waist-shaped groove 7 One end of the first waist-shaped groove 7 is connected to the grid round steel 4 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com