Egg collecting machine

An egg collecting machine and egg collecting technology, applied in the field of egg collecting machines, can solve the problems of high manufacturing and operating costs, space efficiency, long transmission routes, etc., and achieve the effects of reducing operating costs, saving space, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

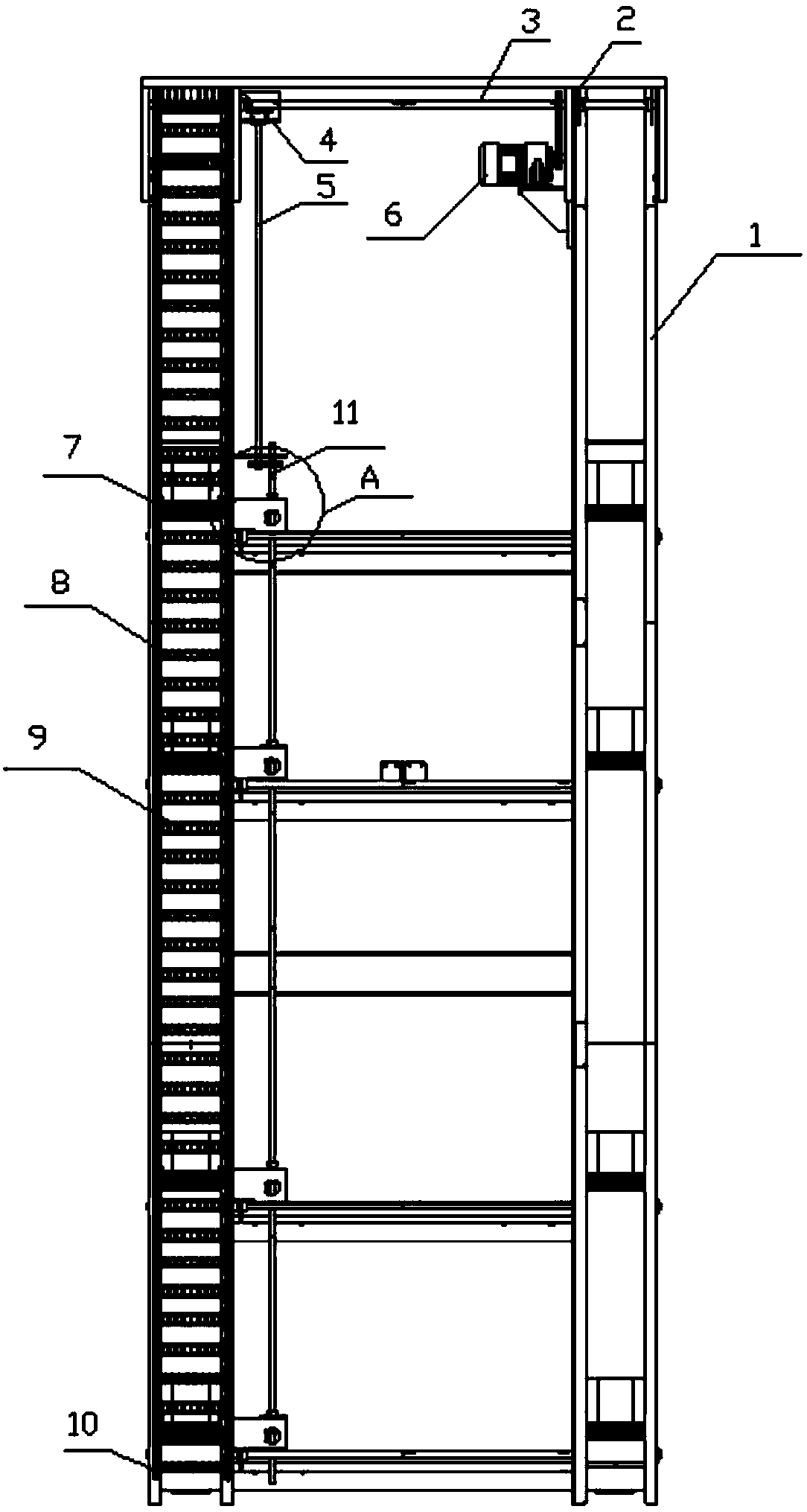

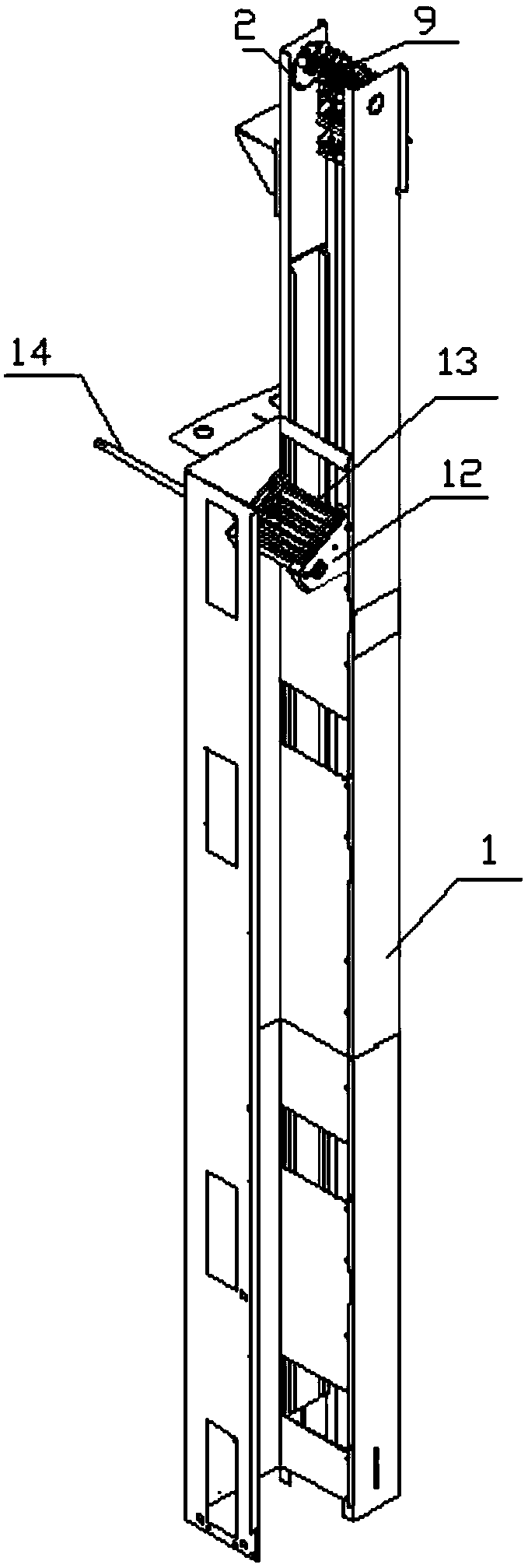

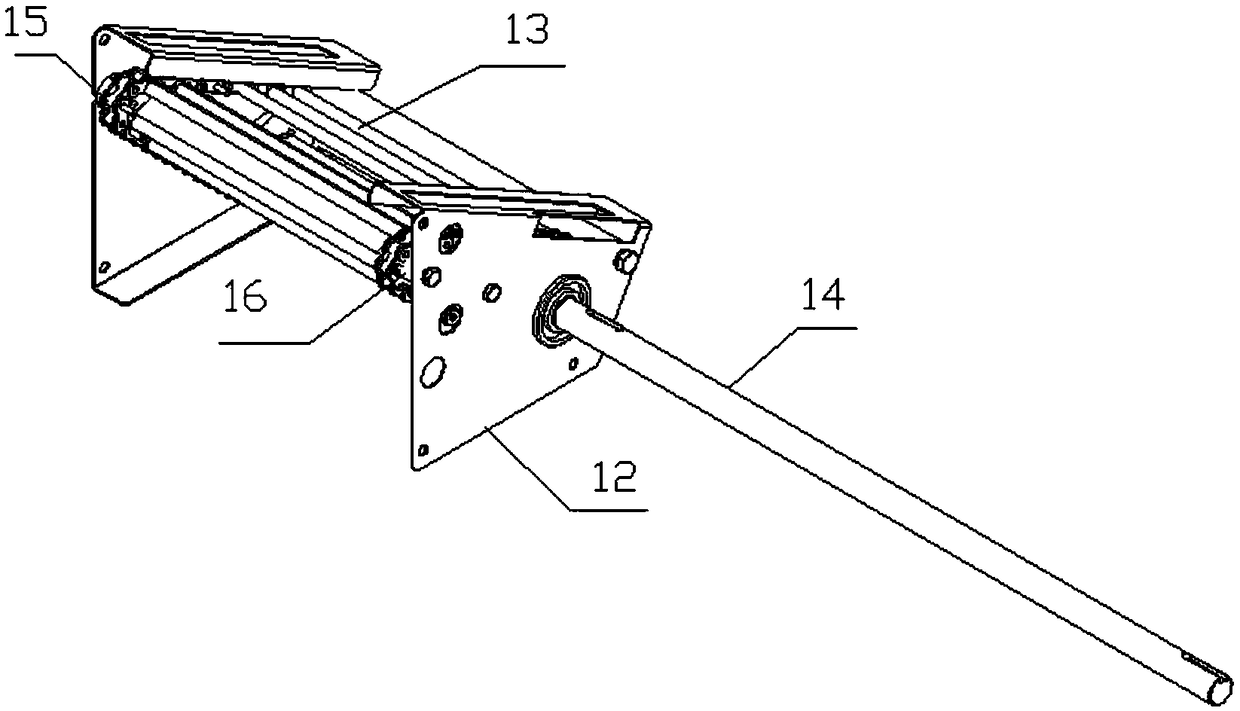

[0029] An egg collection machine, which includes a frame 1, an egg guide device and an egg collection device, the egg collection device is arranged in front of the egg guide device, and the egg collection device includes a longitudinal chain egg collection transmission mechanism and a plurality of egg claws 9. The longitudinal chain egg collection transmission mechanism includes the upper egg collection sprocket 2 installed on the frame, the lower egg collection sprocket 10 and the ring-shaped egg collection sprocket hung between the upper egg collection sprocket and the lower egg collection sprocket. Egg collection chain 8, a plurality of said egg claws are evenly and fixedly installed on the egg collection chain, said upper egg collection sprocket is provided with a horizontal egg collection transmission shaft 3, said horizontal egg collection transmission shaft is driven by a motor 6 and passed through The intermeshed bevel gear 4 transmits power to the longitudinal transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com