Water pipe rust removal device for water conservancy project

A technology for water conservancy projects and water pipes, which is applied in the direction of grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc., and can solve problems such as insufficient water injection, failure to ensure normal use of water pipes, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

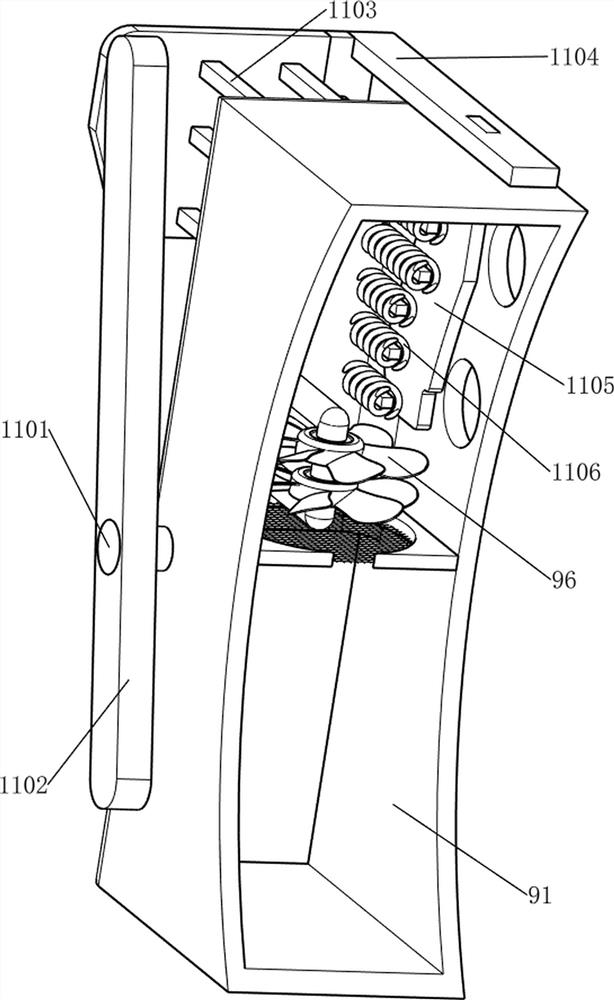

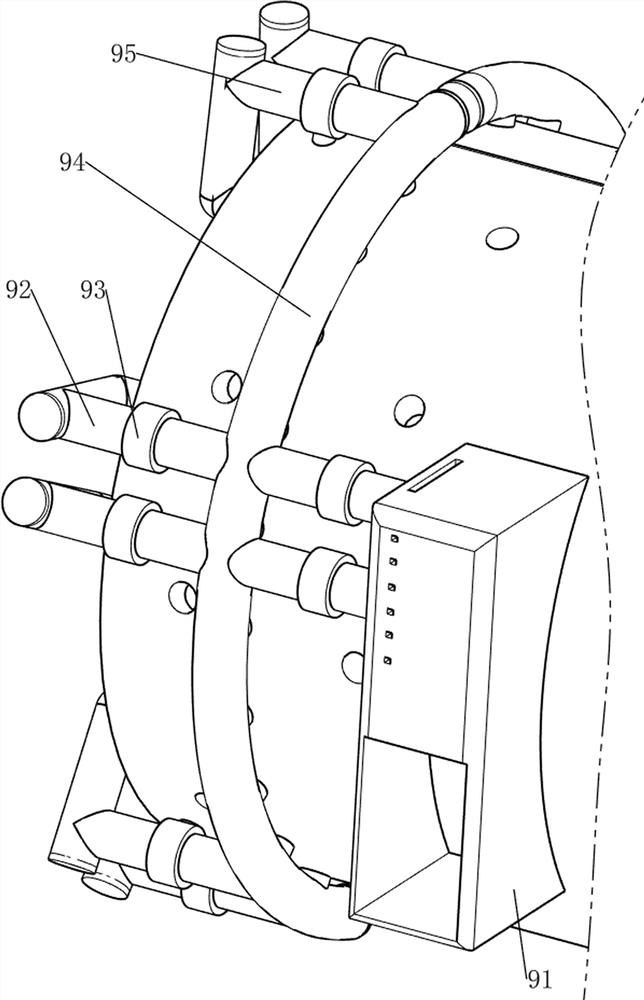

[0077] A water pipe derusting device for water conservancy projects, such as Figure 1-6 As shown, it includes a rotating plate 1, a connecting column 2, a handle 3, a friction plate 4, a first return spring 5, a forward mechanism 6 and a guiding mechanism 7, and the connecting column 2 is rotatably provided with two rotating plates 1, two The lower parts of the rotating plates 1 are provided with handles 3, and ten friction plates 4 are slidingly provided on the two rotating plates 1. The outer sides of the friction plates 4 are all symmetrically wound with first return springs 5, and the number of first return springs 5 is twenty. The first return spring 5 is connected between the connecting column 2 and the friction plate 4 , a forward mechanism 6 is connected between the two rotating plates 1 , and a guiding mechanism 7 is connected between the two rotating plates 1 .

[0078] When the water pipes of water conservancy projects need rust removal, this device can be used. ...

Embodiment 2

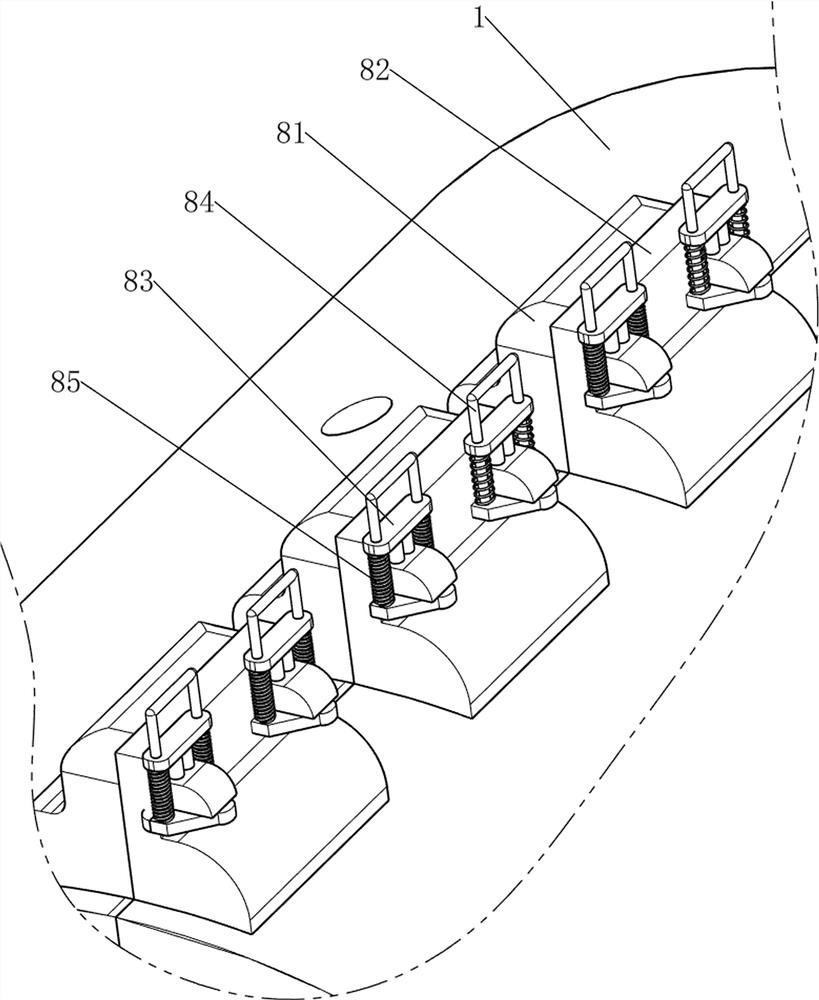

[0084] On the basis of Example 1, such as Figure 7-15 As shown, a locking mechanism 8 is also included, and the locking mechanism 8 includes a flashing plate 81, an orifice plate 82, a double fork lever 83, a thin connecting rod 84 and a fourth return spring 85, and the upper part of the rotating plate 1 on the left is provided with three inserting Plate 81, three orifice plates 82 are arranged on the upper part of the rotating plate 1 on the right side, and the orifice plate 82 on the same side is slidably connected with the inserting plate 81 on the same side. Double-fork rods 83 are slidingly arranged on the thin connecting rod 84, and the two double-fork rods 83 on the same side are all engaged with the inserting plate 81 on the same side. , the fourth return spring 85 is connected between the thin connecting rod 84 and the double-fork rod 83 .

[0085] When the locking mechanism 8 is used, the rotating plate 1 encircles the water pipe at this time. When the main water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com