Laser rust remover and rust removing method thereof

A technology of laser rust removal and laser beam, which is applied in the direction of laser welding equipment, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of parts burn, high cost, and different shapes, so as to achieve convenient placement and avoid errors , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

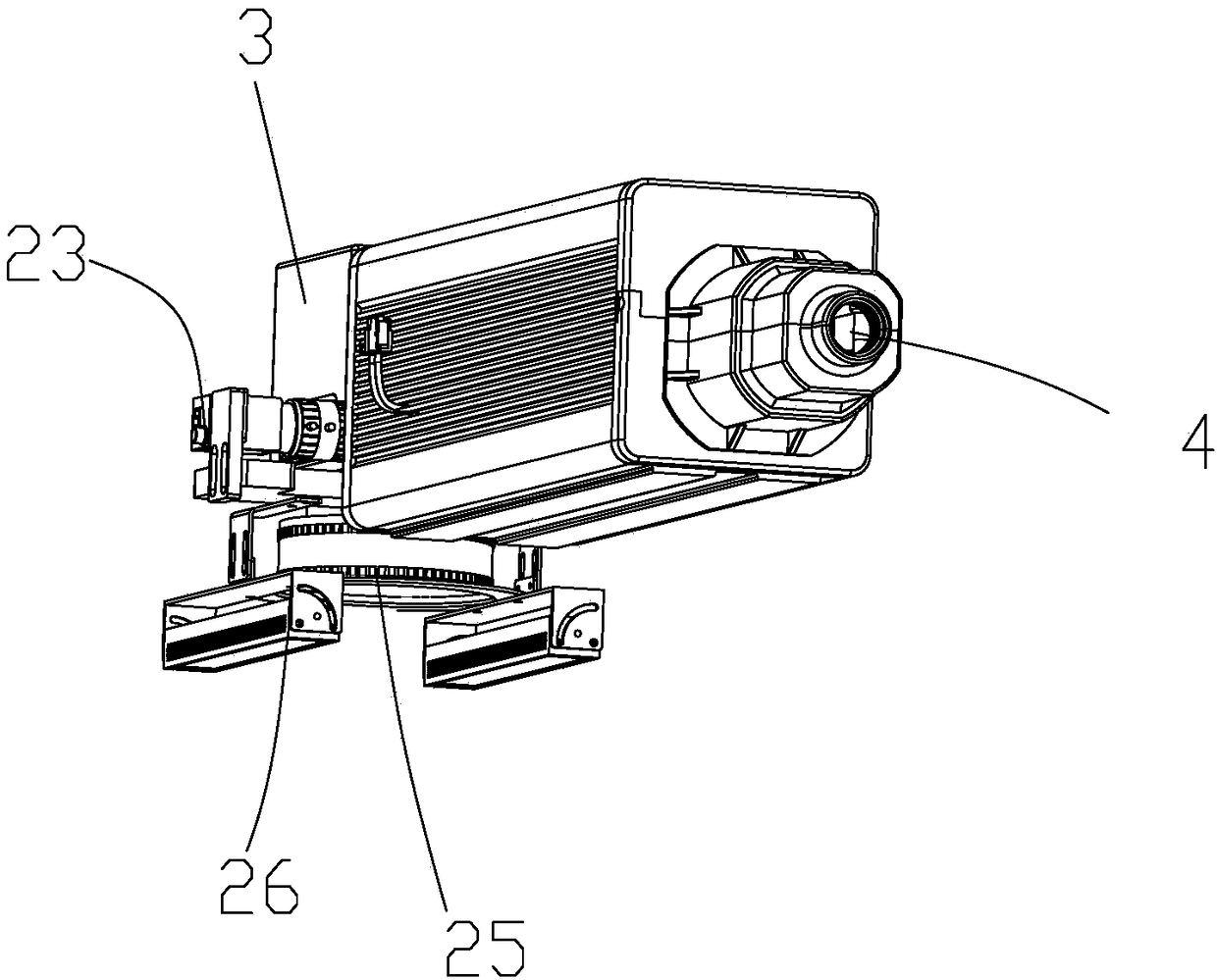

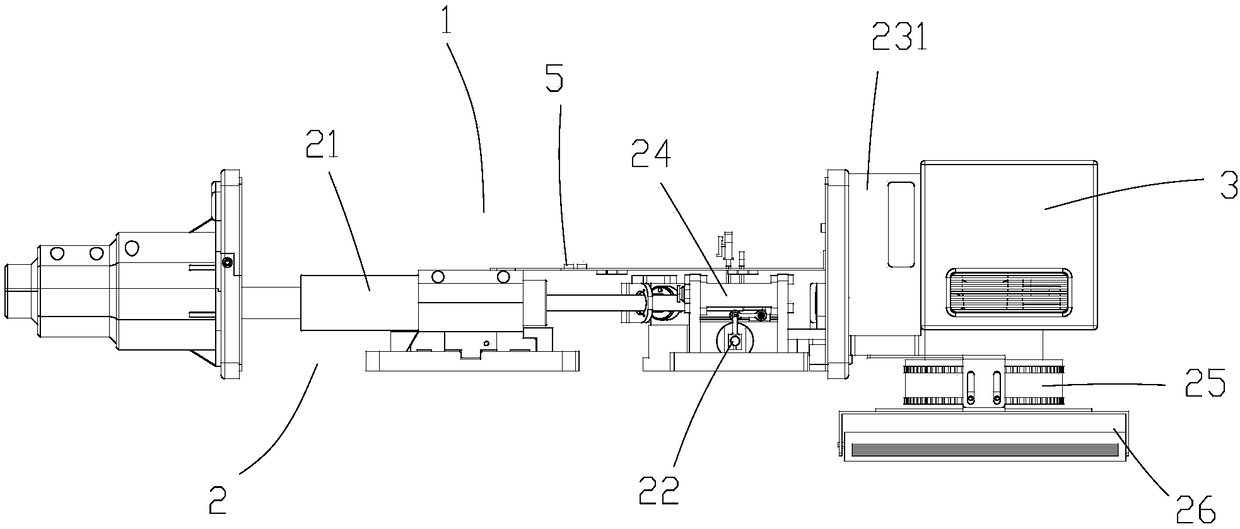

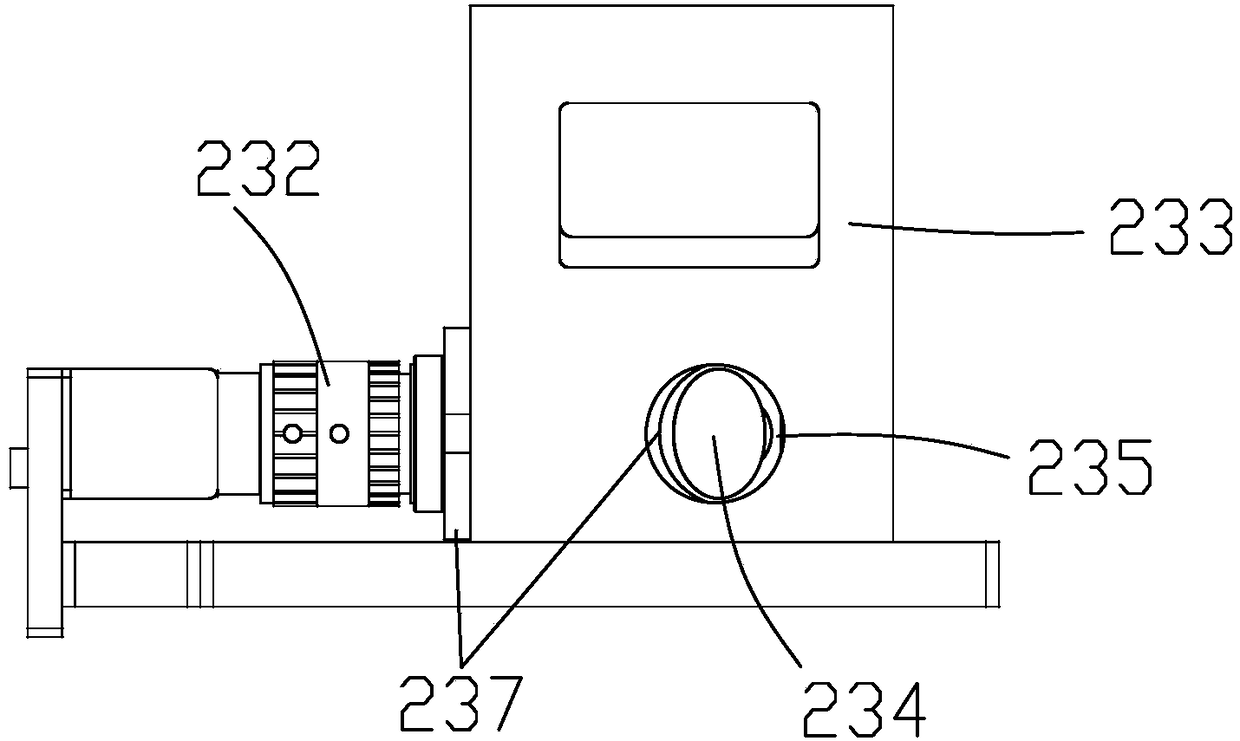

[0049] Such as Figures 1 to 8 As shown, this embodiment provides a laser descaling machine, including a wire feeder 4 connected to one end of the cavity and coaxial with it, and a vibrating mirror part 3 connected to the other end of the cavity. The axis is the upper cavity 1 and the lower cavity 2 formed by the division of the dividing line. There is a partition 5 between the upper cavity 1 and the lower cavity 2. The upper cavity 1 is provided with a plurality of wire feeders 4 extending into the upper cavity. The circuit wires of the chamber, a plurality of said circuit wires extend into the vibrating mirror part 3 from the other end of the upper chamber 1, and a transmitter 21, a zoom Device 22 and camera system 23;

[0050] The input end of the transmitter 21 is connected to the circuit line in the wire feeder 4, and the output end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com