Fishing pendant

A fishing pendant and integrated technology, applied in the field of fishing pendants, can solve the problems of rebound injury, fish pendant and hook fishing line falling off, fish pendant easy to fall into rock cracks, etc., and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

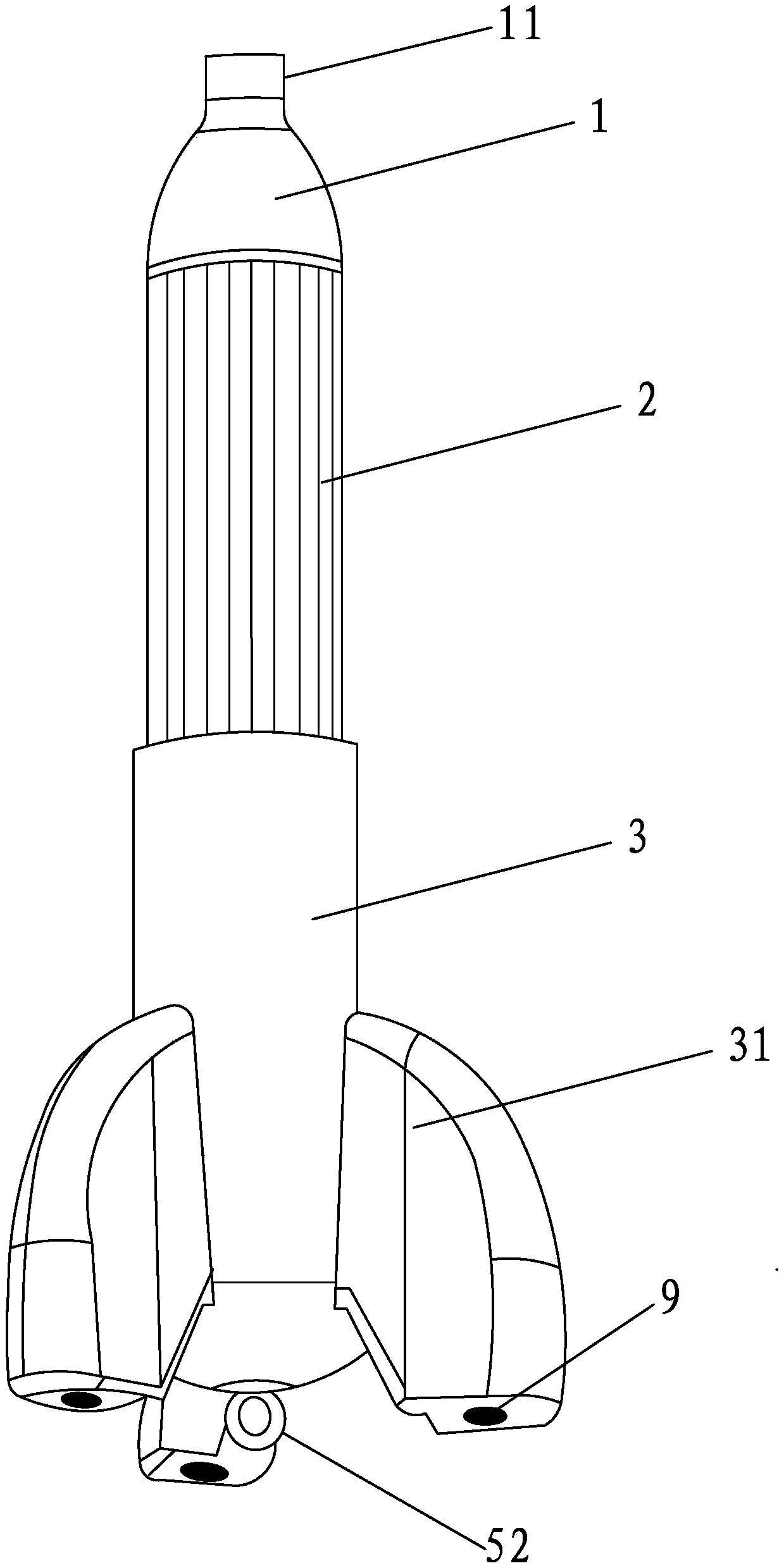

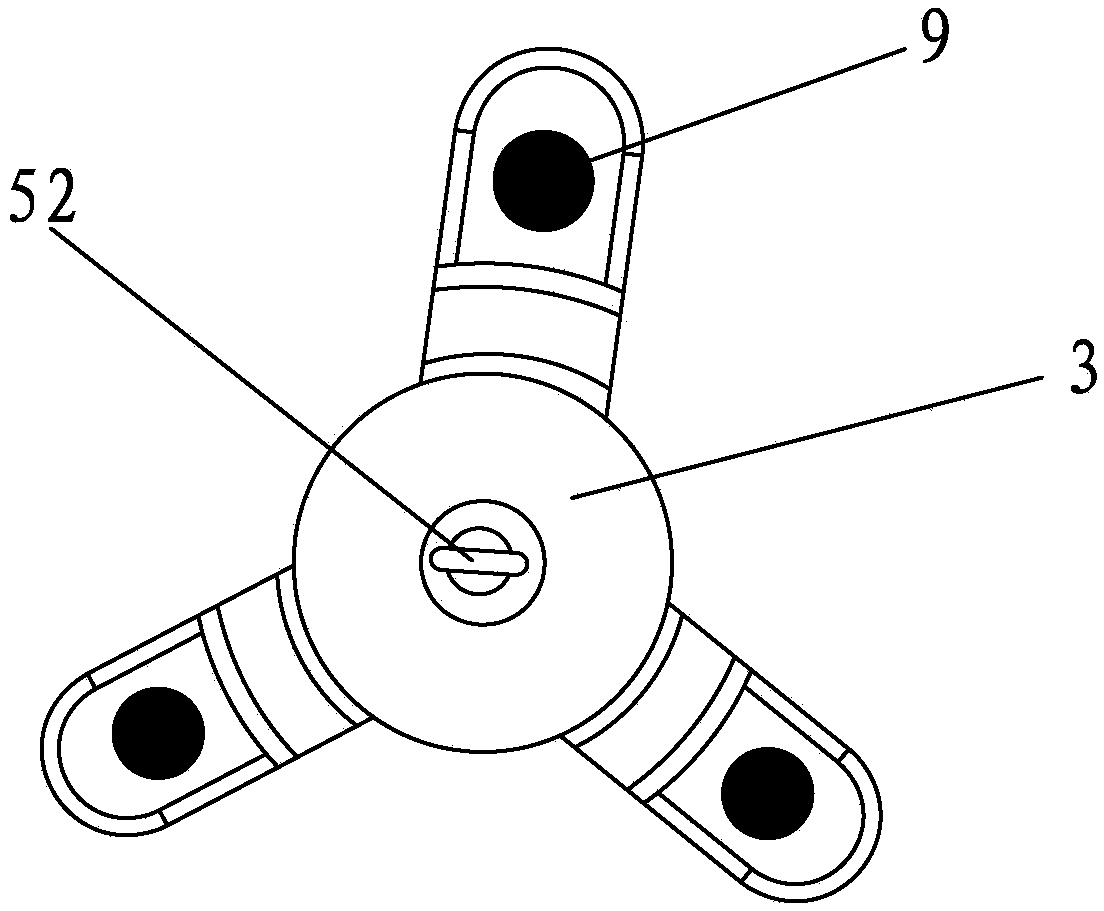

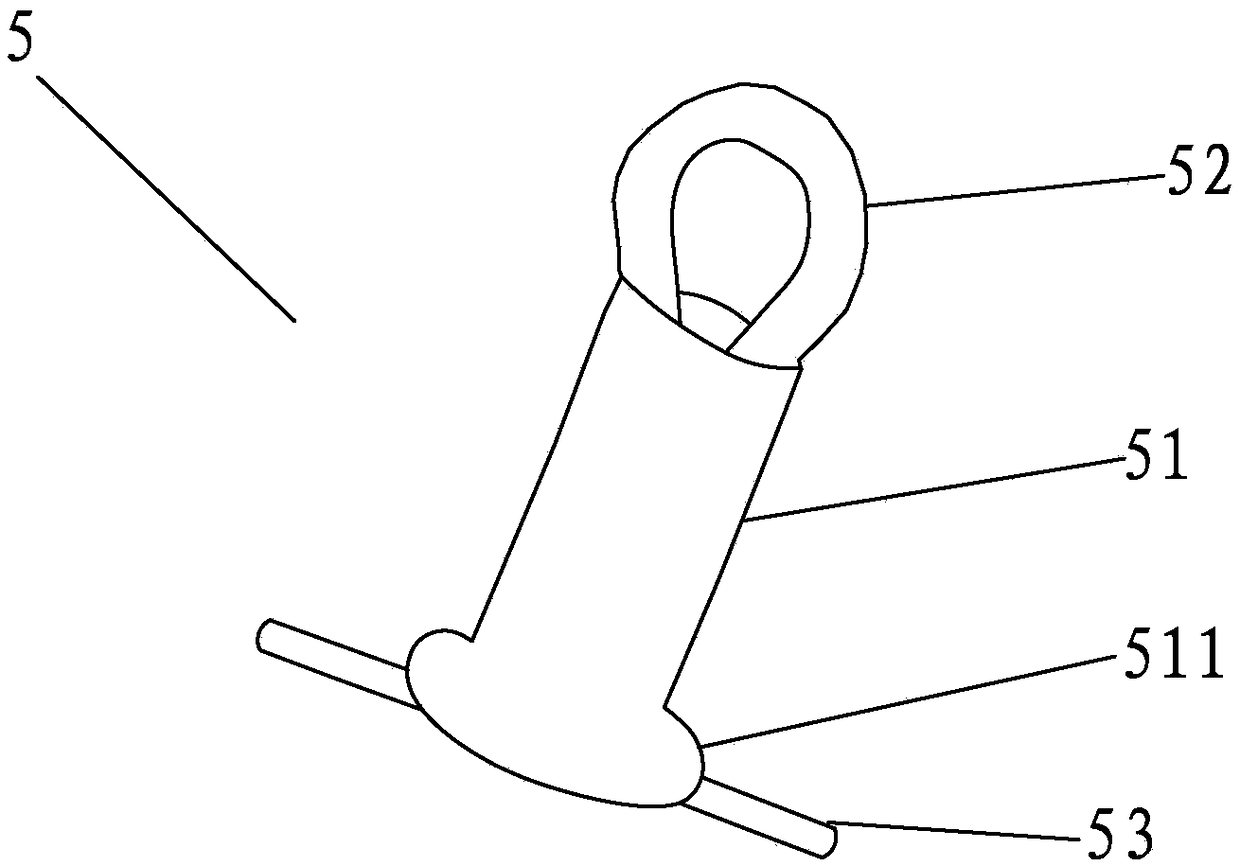

[0025] A kind of fishing weight of the present invention, such as Figure 1-4 As shown, it includes a weight head 1, an aluminum connector 2 and a plastic head 3. The aluminum connector 2 is a hollow aluminum tube with open ends, that is, the aluminum connector 2 is a hollow cylinder structure, and the weight head 1 is a lead block. body, the lead block body is provided with a reinforcing rod 4 integrally cast with the lead block body, one end of the counterweight head 1 extends into the first end port of the aluminum connector 2 and is fixed together with the aluminum connector 2, and the counterweight head 1 The other end is outside the aluminum connector 2, and the plastic head 3 is a hollow pipe body whose one end is an open end and the other end is a closed end. And be fixedly connected with the plastic head 3, the plastic head 3 is fixedly installed with the threading coil 5 outside the closed end of the plastic head 3, and the outer wall of the plastic head 3 is protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com