Internet router reticle interface machining equipment

A technology for processing equipment and routers, which is applied in the direction of manufacturing tools, punching machines, presses, etc., and can solve the problem that there is no way to process square metal sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

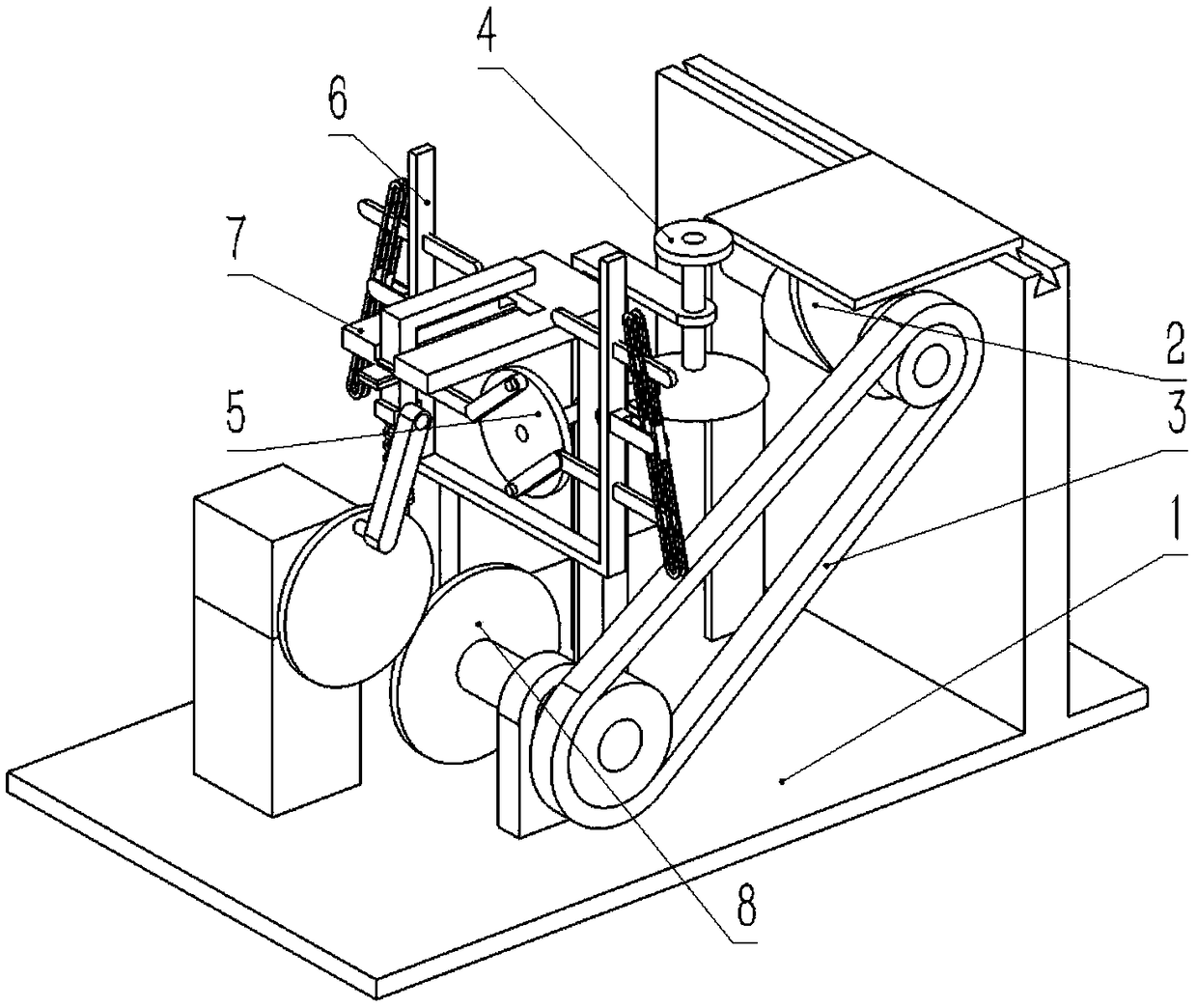

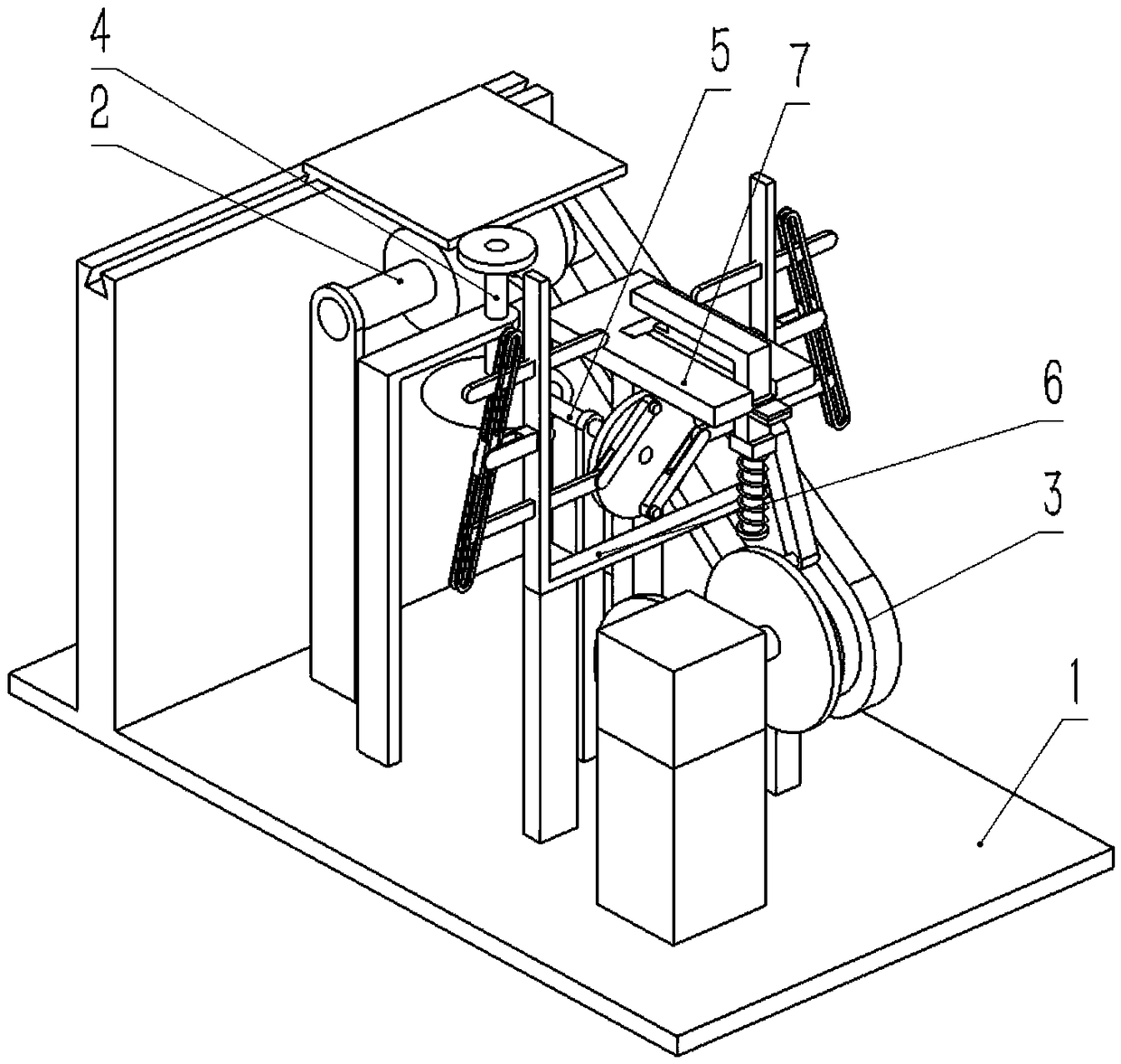

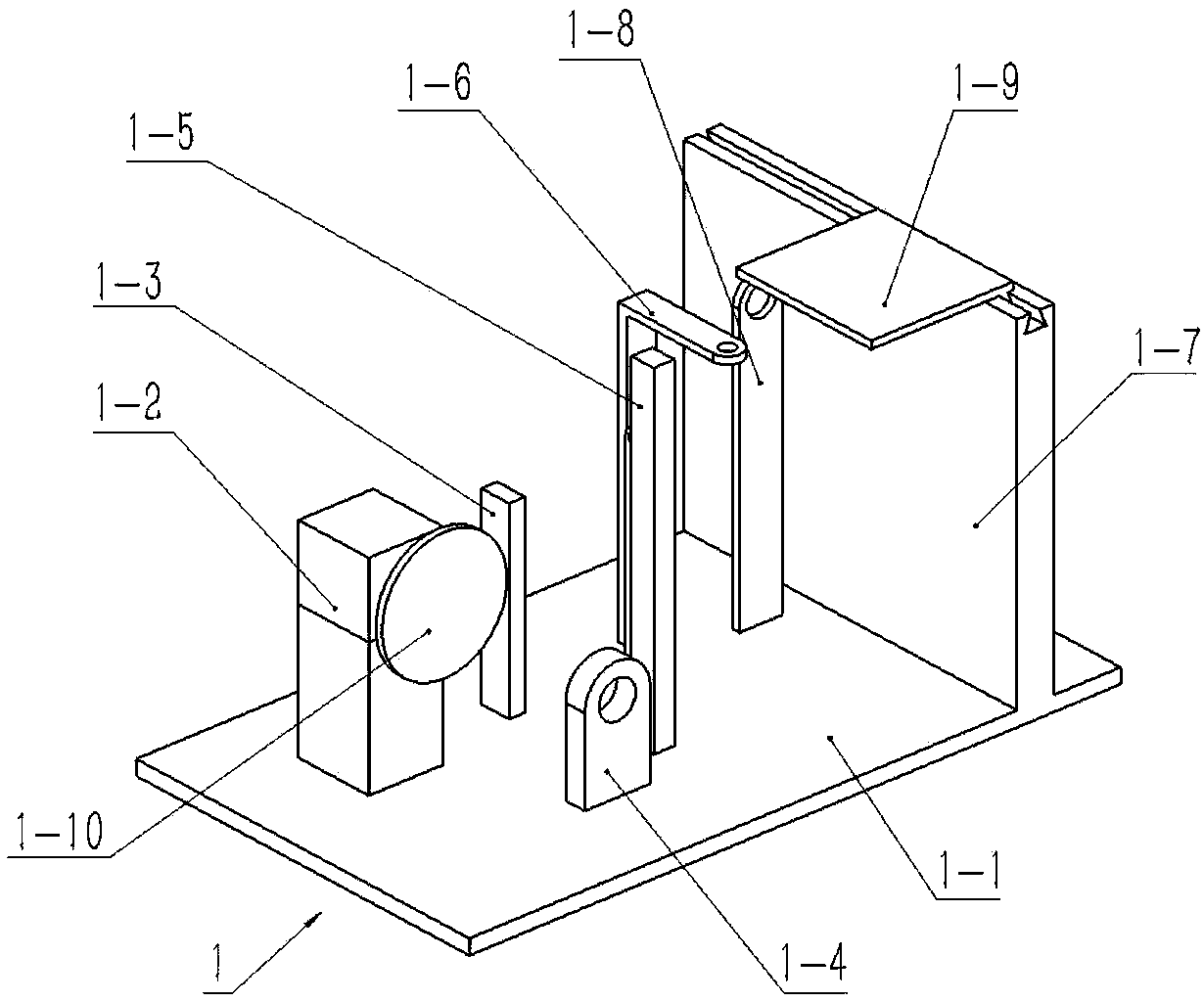

[0036] Combine below Figure 1-16Describe this embodiment, an Internet router network cable interface processing equipment, including a chassis assembly 1, a cylindrical roller assembly 2, a synchronous belt 3, a secondary transmission assembly 4, a lateral input assembly 5, and a push rod assembly 6. Compression rod assembly 7 and roller transmission assembly 8. The chassis assembly 1 includes a bottom plate 1-1, a motor 1-2, a push rod assembly fixing rod 1-3, and a roller transmission rotating plate 1-4. , pressure rod combination fixed rod 1-5, secondary transmission rotating rod 1-6, slide plate 1-7, cylindrical roller rotating rod 1-8, rack plate 1-9, input gear 1-10 and horizontal input rotating rod Rod 1-11, the rack plate 1-9 includes a rack plate body 1-9-1, a trapezoidal slider 1-9-2 and a sliding column 1-9-3, and the sliding column 1-9-3 Welded on the middle end of the rack plate body 1-9-1, the trapezoidal slider 1-9-2 is fixedly connected to the right end of th...

specific Embodiment approach 2

[0049] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain Embodiment 1, the annular chute 2-4 is an annular closed structure, so that the sliding column 1-9-3 can reciprocate in the annular chute 2-4, which is transformed into The reciprocating motion of the sliding column 1-9-3 moving back and forth laterally, drives the rack plate body 1-9-1 to move through the sliding column 1-9-3, and drives the secondary transmission through the rack plate body 1-9-1 The movement of the straight teeth 4-1 drives the movement of the secondary transmission shaft 4-2 through the secondary transmission straight teeth 4-1, thereby driving the movement of the secondary transmission bevel teeth 4-3, through the secondary transmission bevel teeth 4-3 and The transmission of the transverse bevel gear 5-5 drives the transverse input shaft 5-4 to rotate, thereby driving the transverse runner 5-1 to rotate back and forth.

specific Embodiment approach 3

[0050] Combine below Figure 1-16 This embodiment will be described. This embodiment will further describe the first embodiment. The depth of the rectangular groove I7-1-1 is smaller than the depth of the rectangular groove II7-1-2, which is convenient for pressing the metal sheet.

[0051] An Internet router network cable interface processing equipment of the present invention, its working principle is: when processing, place the iron piece in the rectangular slot I7-1-1, press the button switch SB1 to make the motor 1-2 energized and rotate, press the bar The initial position of the connecting rod 7-3 is at the highest point of the input gear 1-10. When the input gear 1-10 drives the pressing rod connecting rod 7-3 to move to 1 / 4 stroke, the up stroke terminal 7-4 and the down stroke The stroke terminal 7-5 is disengaged, and the stroke normally closed switch SQ1 connected between the upper stroke terminal 7-4 and the lower stroke terminal 7-5 is closed, so that the motor 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com