Tablet press and tablet pressing method thereof

A tableting machine and tableting technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as low degree of automation, and achieve the effect of realizing automation, compact structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

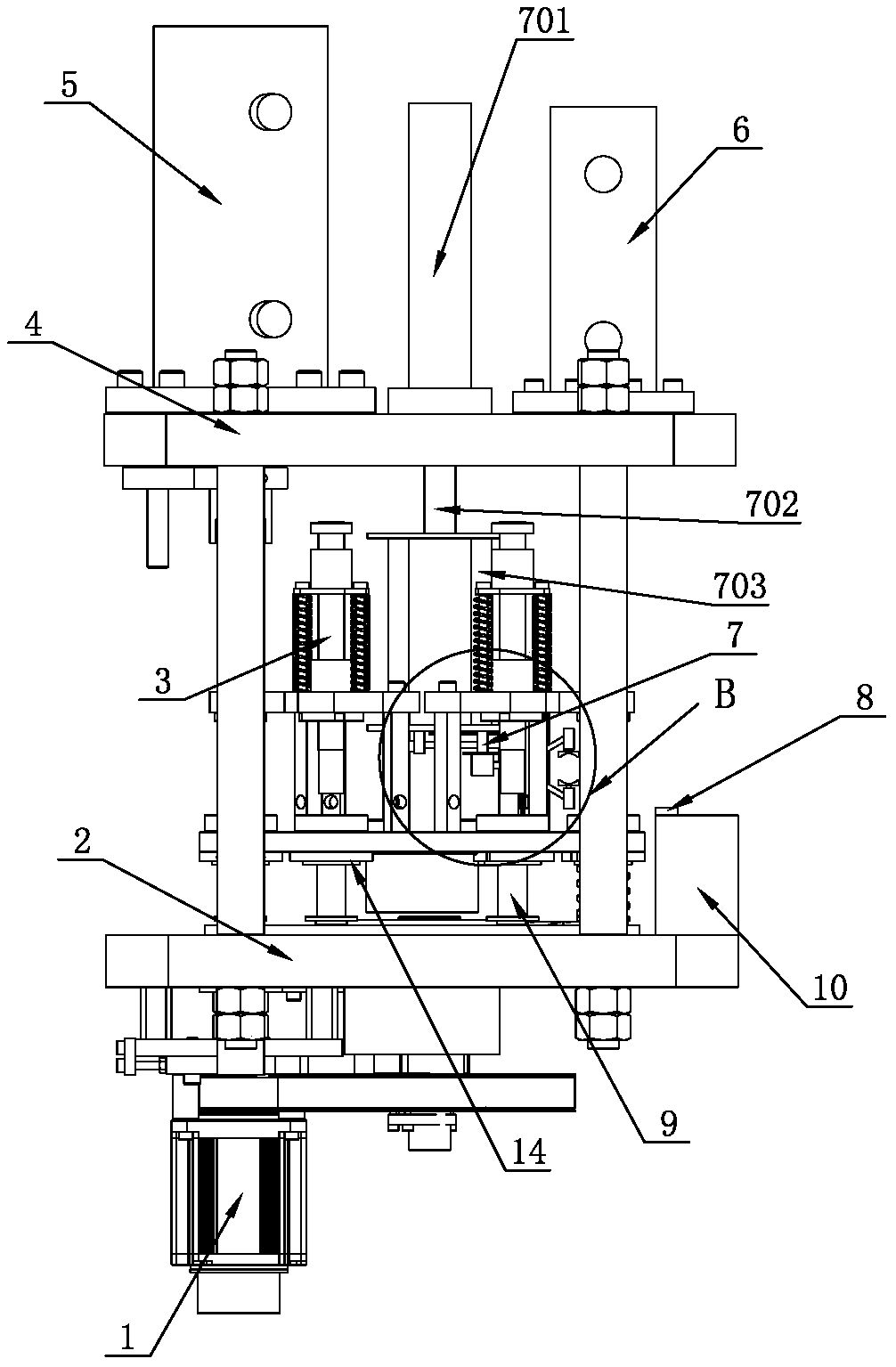

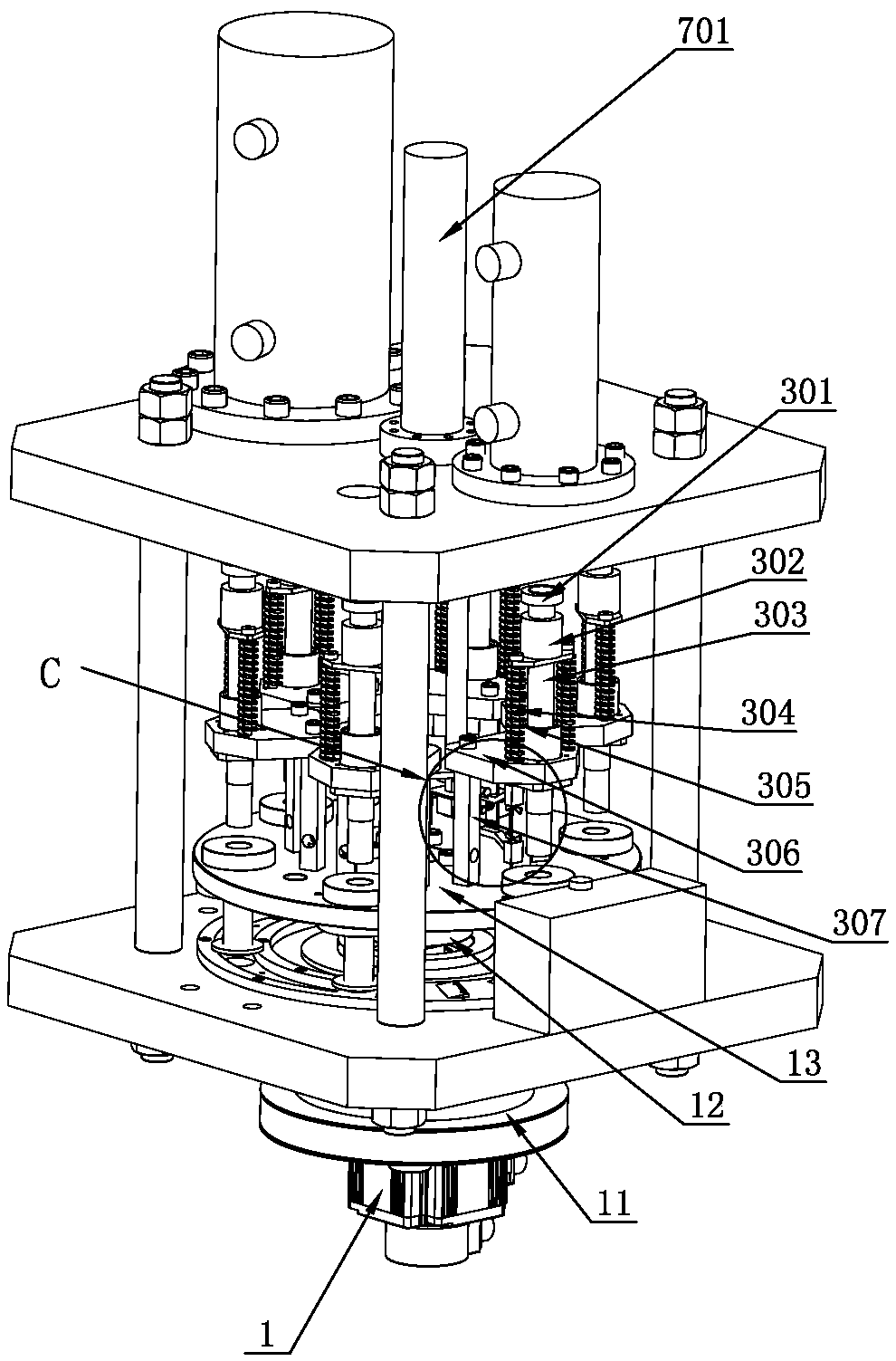

[0043] Such as Figure 1 to Figure 11 A tablet press shown includes a base 2, a rotatable working platform 13 and a clamping mechanism 7 that can move linearly in the height direction, and several dies 14 with a cavity 15 are arranged on the working platform 13 and a plurality of tablet pressing mechanisms corresponding to the die 14, a support base 4 is supported above the base 2, a pre-compression linear driver 5 and a tablet compression linear driver 6 are arranged on the support base 4, and a pre-compression linear driver 5 is provided with a The pre-compression rod 303 that reciprocates linearly in the height direction is provided with a punching rod 303 that can reciprocate linearly in the height direction on the tablet linear driver 6. The pre-compression rod 303 and the punching rod 303 are used to press the Powder, the working platform 13 is set between the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com