A linear motor type portable forming equipment and portable forming method

A technology of linear motors and forming equipment, applied to cardboard items, etc., can solve the problems of poor forming effect and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

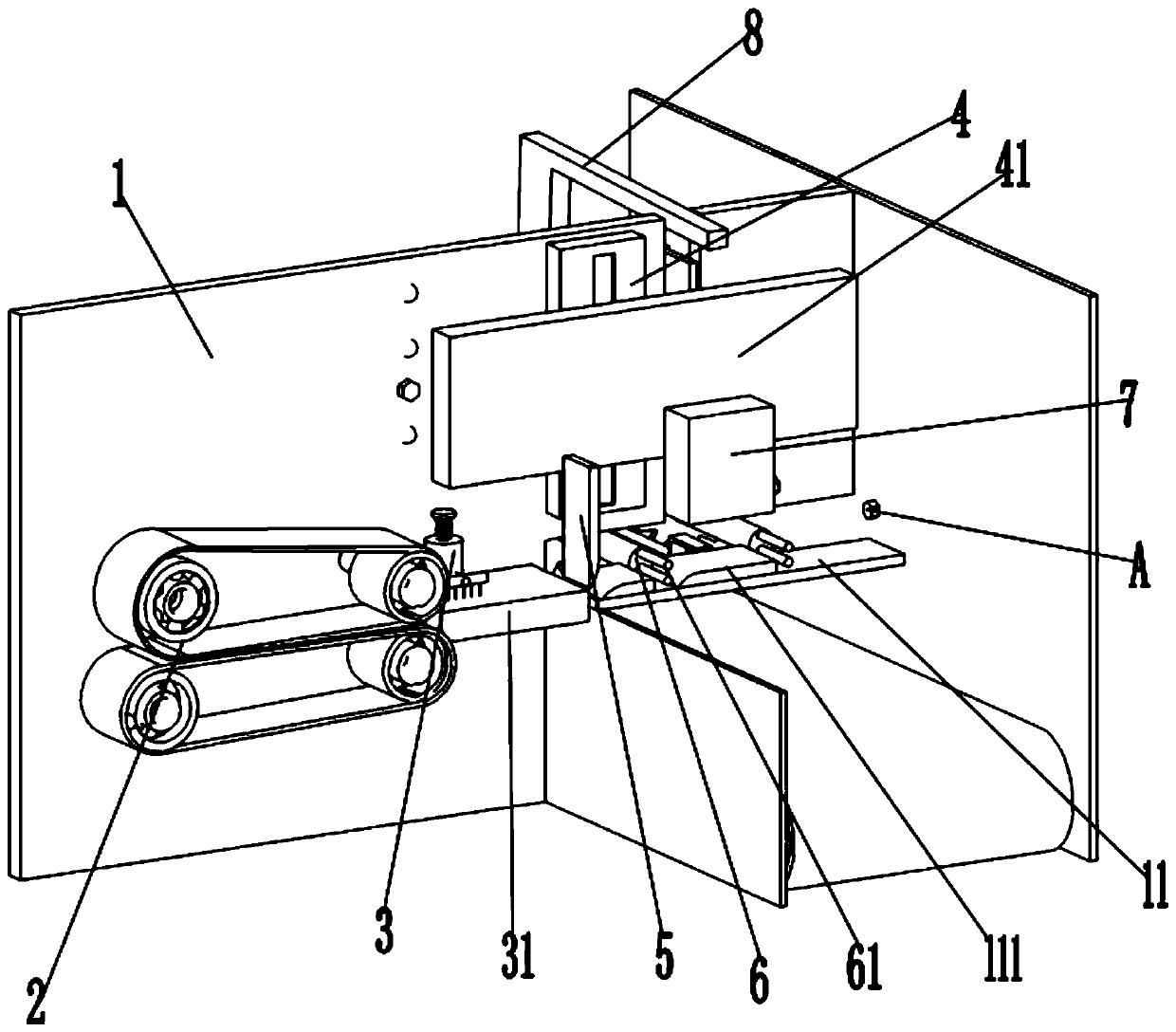

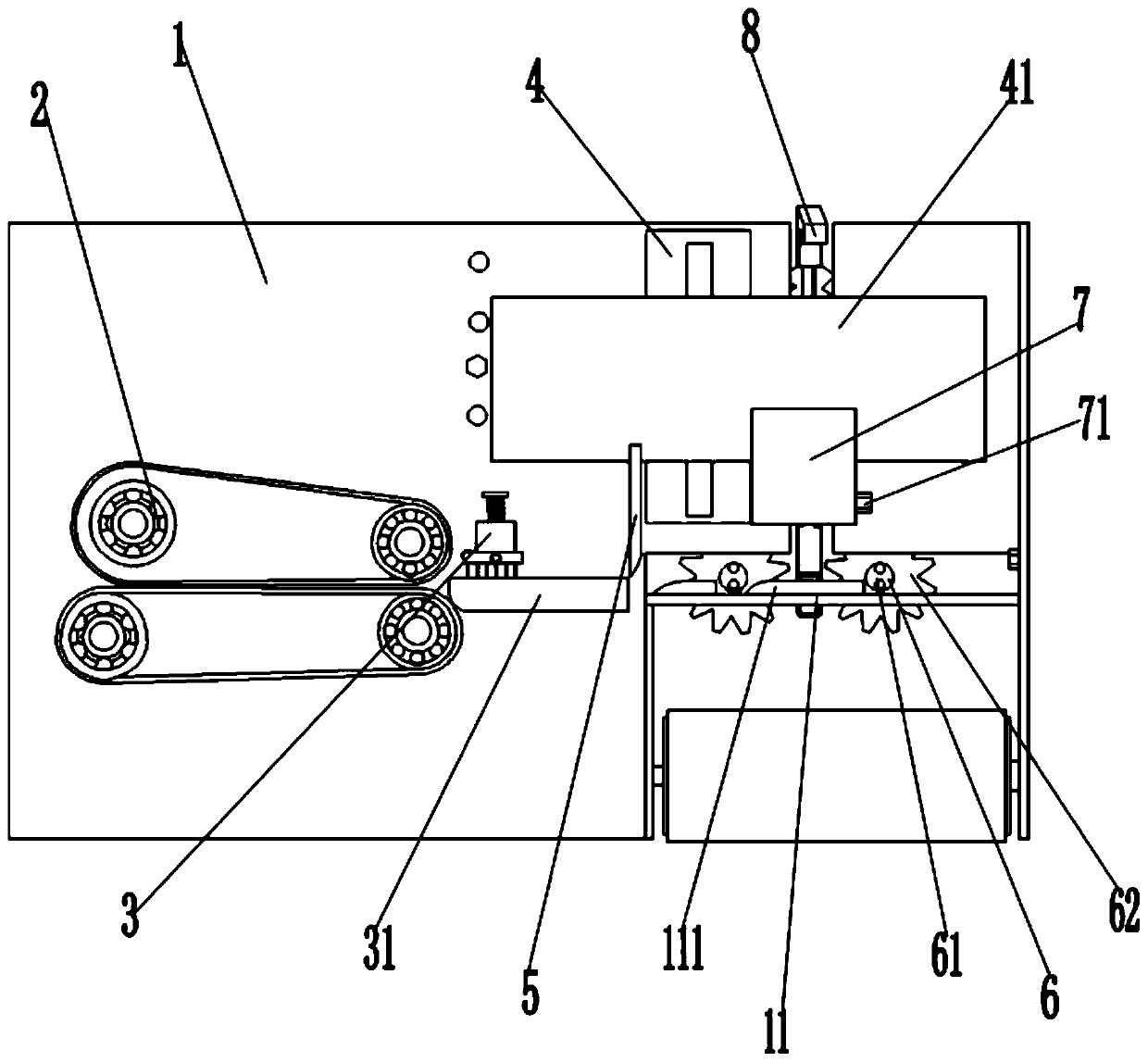

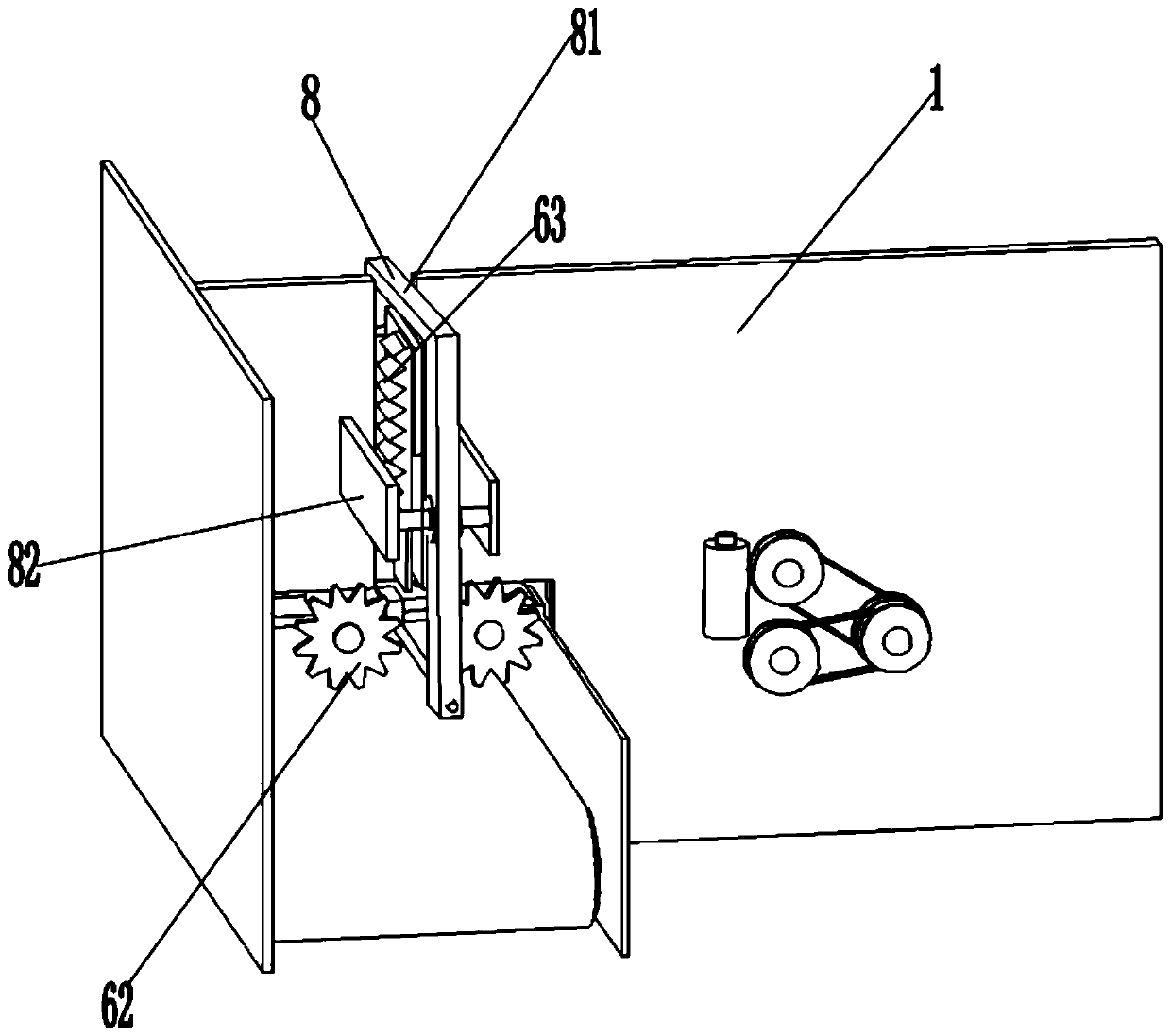

[0045] Such as Figure 1-2 As shown, a linear motor-type portable forming equipment includes: a working plate 1, a transmission mechanism 2, a gluing mechanism 3, a linear motor 4, a cutter 5, a folding mechanism 6, a pressing block 7, and a separation mechanism 8;

[0046] The working board 1 is composed of two side boards The template is set vertically;

[0047] The transmission mechanism 2 is arranged on the lateral side pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com