A laser cutting device and a wallpaper laying device

A cutting device, laser technology, applied in decorative arts, pasting and other directions, to achieve high efficiency, improve the quality of paving, high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

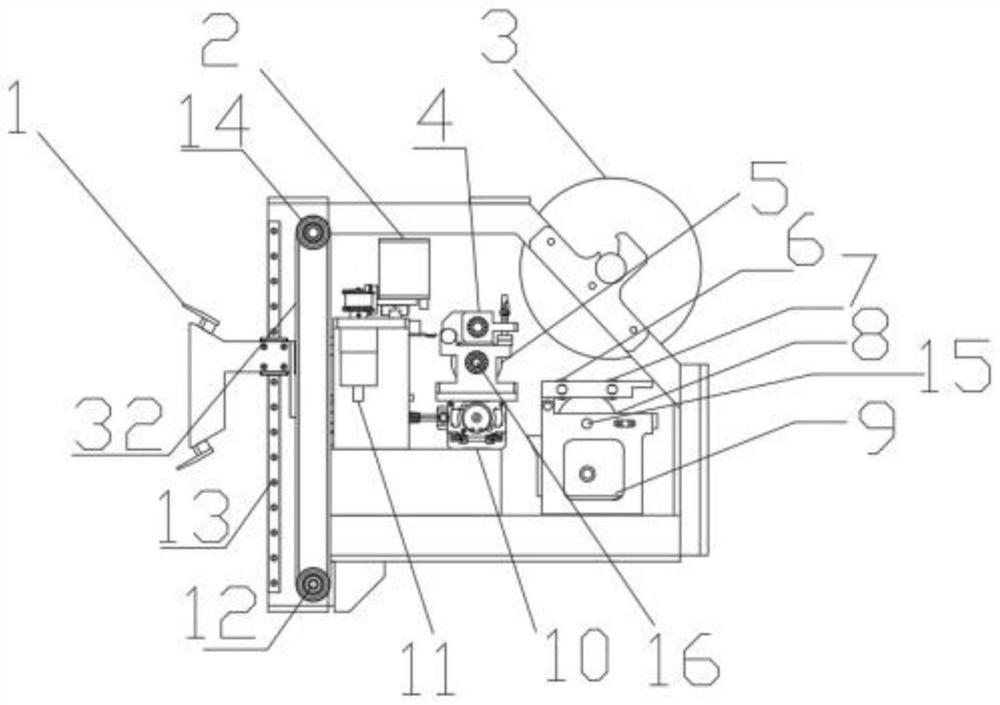

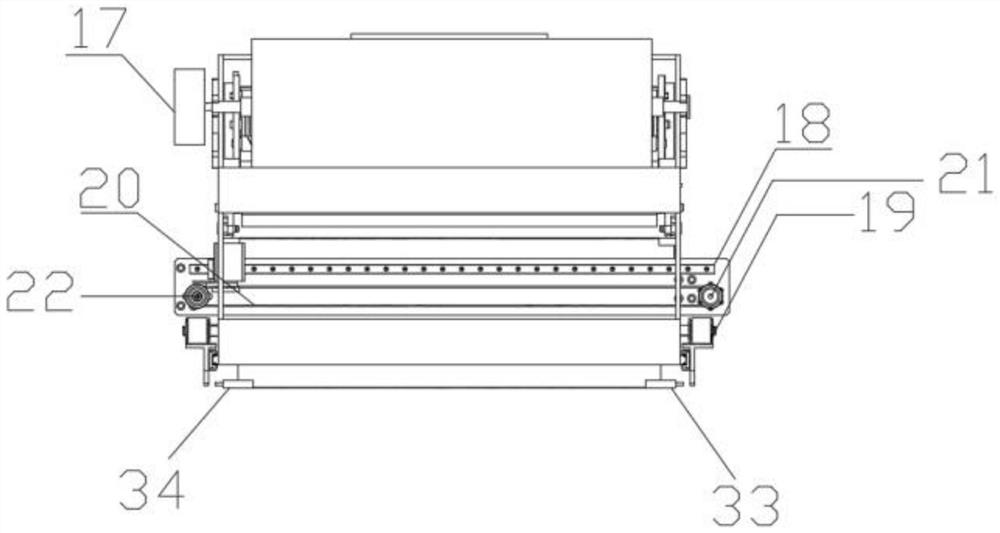

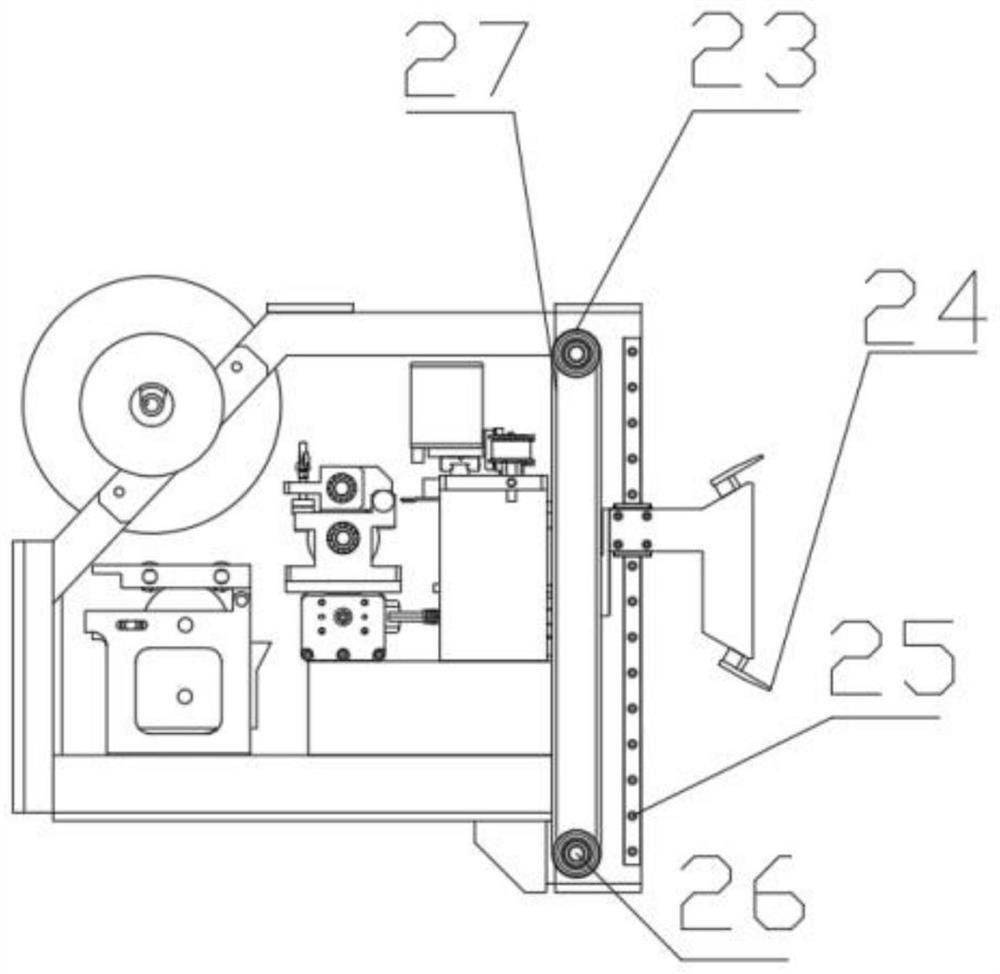

[0033] Such as Figure 1 to Figure 7 As shown, the present invention provides a kind of laser cutting device, comprises laser cutting device support 35, laser cutter 2 and first transmission device; Laser cutting device support 35 is provided with first guide rail 18 along horizontal direction, and laser cutter 2 can Slidingly arranged on the first guide rail 18; the first transmission device is arranged on the laser cutting device bracket 35, and is connected with the laser cutter 2, thereby driving the laser cutter 2 to slide on the first guide rail 18, that is, the first transmission device It is used to drive the laser cutter 2 to slide horizontally along the first guide rail 18, thereby realizing wallpaper cutting; the laser cutting device provided by the present invention has a simple structure and is practical, and can be directly applied to a wallpaper laying device to realize automatic cutting and avoid manual cutting labor. The problem of high strength, low efficienc...

Embodiment 2

[0038] Such as Figure 1 to Figure 7 As shown, the present invention provides a wallpaper paving device, including a laser cutting device and a frame body 31, the laser cutting device is the above-mentioned laser cutting device; the laser cutting device is fixedly arranged on the frame body 31 along the horizontal direction .

[0039] Preferably, in combination with the above schemes, such as Figure 1 to Figure 7 As shown, in this embodiment, the wallpaper paving device also includes a gluing component, a deviation correcting component, a laser cutting device, a scraper component and a paving component; wherein, the gluing component, a deviation correcting component, a laser cutting device, a scraper component and The paving parts are sequentially arranged on the frame body 31 along the horizontal direction; the gluing parts are arranged on the back side of the frame body 31, and the scraper parts can be reciprocated up and down and arranged on the front side of the frame bo...

Embodiment 3

[0051] Correspondingly, combining the above schemes, such as Figure 1 to Figure 8 Shown, the present invention also provides a kind of wallpaper automatic paving method, comprises following process:

[0052]S1: The wallpaper is glued through the gluing part; the specific gluing process can refer to the above-mentioned embodiment;

[0053] S2: After gluing, the wallpaper will be corrected and adjusted through the deviation correcting parts through the transmission, so as to avoid the deviation of wallpaper from affecting the quality of paving;

[0054] S3: The wallpaper after deflection correction is cut by a cutting device;

[0055] S4: The cut wallpaper is laid by the laying parts; it should be noted that the cutting process can be carried out at the same time, and there is no conflict between the two operations;

[0056] S5: Finally, the end of the wallpaper is pasted by the scraper part.

[0057] Preferably, in combination with the above schemes, such as Figure 1 to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com