Large-sized seagoing vessel berth stabilizing device

A technology of anti-rolling device and bed, which is applied in the direction of the bed in the engine room, reducing the movement of the ship through the displacement, and the living quarters. It can solve the problems of discounting work efficiency, single anti-rolling principle, and affecting the sleep quality of the crew, and achieves a good shock-absorbing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

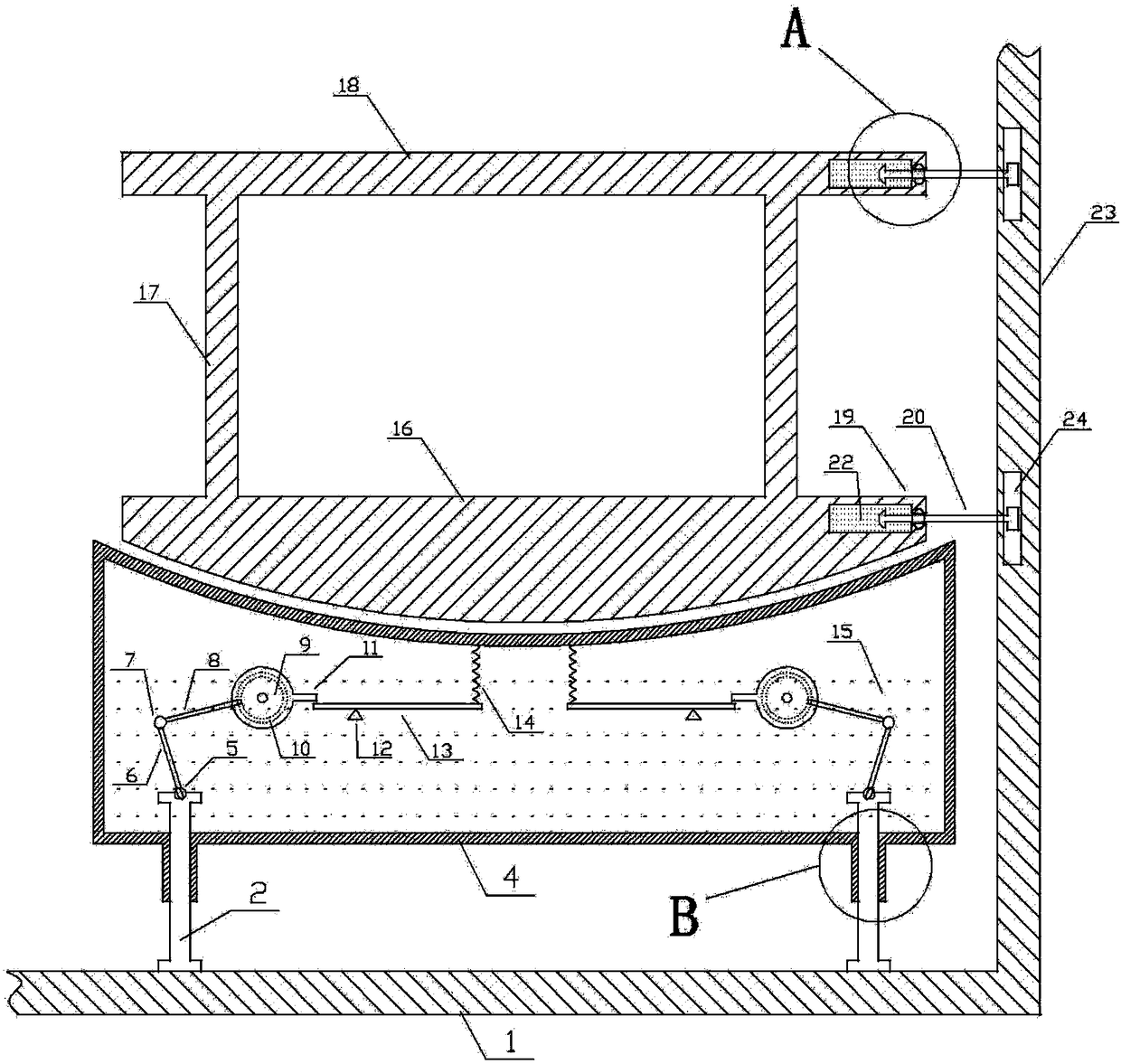

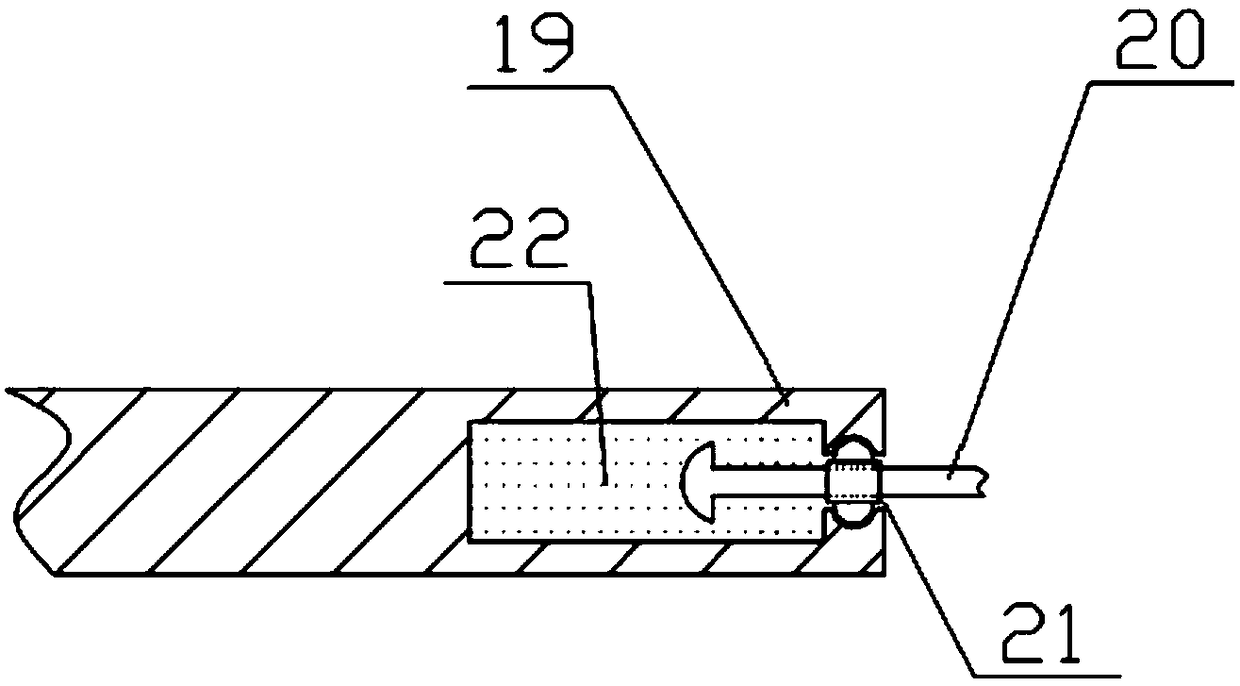

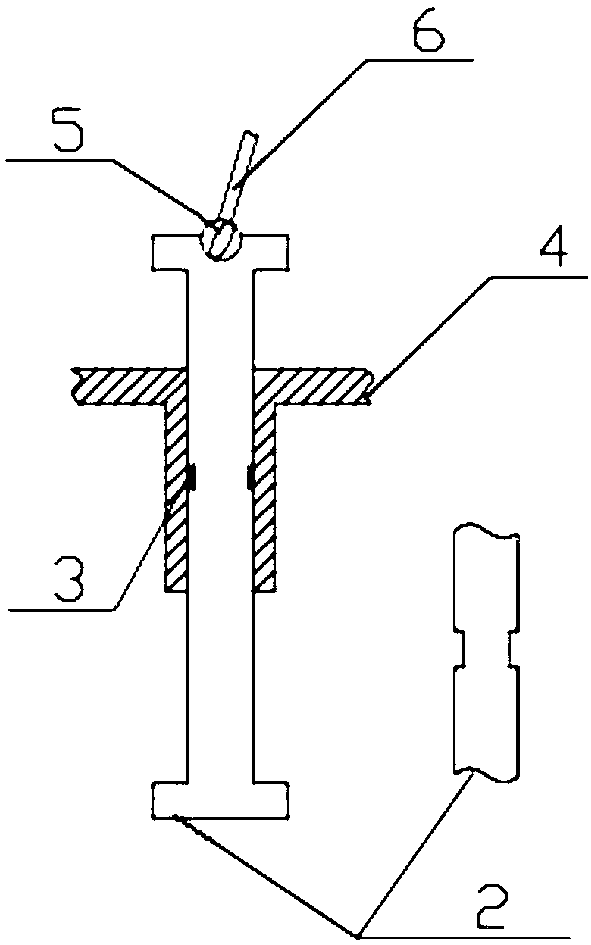

[0023] Below through embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as shown in the figure figure 1 and figure 2 As shown, the vertical guide post 2 is in free contact with the deck ground 1 of the ship, and a groove is engraved in the middle of the vertical guide post 2, and a sealing gasket 3 is arranged in this area, and the vertical guide post 2 is nested in the bottom of the liquid tank 4 vertically downward In the protruding tubular structure, in order to ensure that the vertical guide column 2 does not leak liquid when it moves vertically, the upper and lower ends of the vertical guide column 2 are provided with limiting structures protruding to both sides to prevent the vertical guide column from leaking. 2 is separated from the liquid tank 4 structure, and the upper end of the vertical guide column 2 is connected with the crank 6 through the universal joint A5 to ensure that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com