Multidirectional automatic recording system and method for spindle position information corresponding to bobbin yarn

A technology of spindle positions and bobbins, which is applied in the field of multi-directional automatic recording of spindle position information corresponding to bobbins, can solve problems such as reducing the service life of bobbins with electronic tags, affecting bobbin forming, and losing the function of electronic tags, etc., so as to avoid spindle The effect of incorrect and accurate spindle position information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

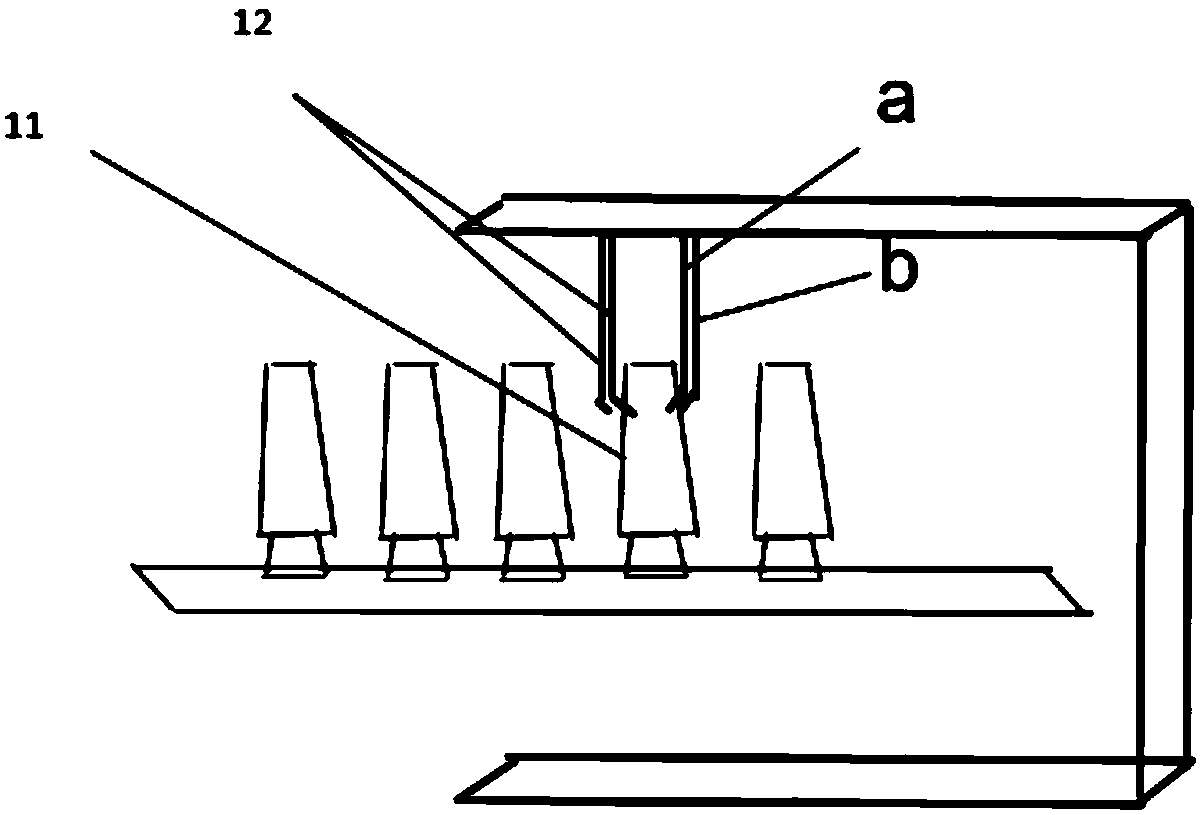

[0039] This embodiment provides a device for determining the spindle position information corresponding to the bobbin, see figure 1 , the device includes:

[0040] At least two bobbin readers;

[0041] The bobbin reader / writer is used to read and write the electronic label on the bobbin;

[0042] At least two bobbin reader-writers among the at least two bobbin reader-writers simultaneously read and write the electronic tags on the same bobbin.

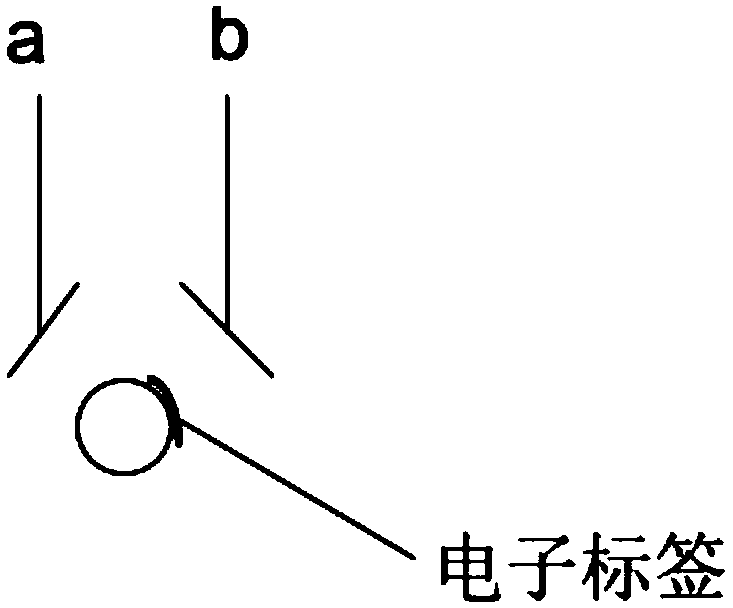

[0043] Such as figure 1 As shown, in this embodiment, the device for determining the spindle position information corresponding to the bobbin includes two bobbin readers and writers as an example for illustration. The two bobbins are respectively marked as a and b. Readers a and b read or write the bobbins at the same time, and the schematic diagram of the positions of the bobbin readers a and b and the bobbin being read or written is as follows: figure 2 as shown in figure 2The orientation of the electronic label shown is consi...

Embodiment 2

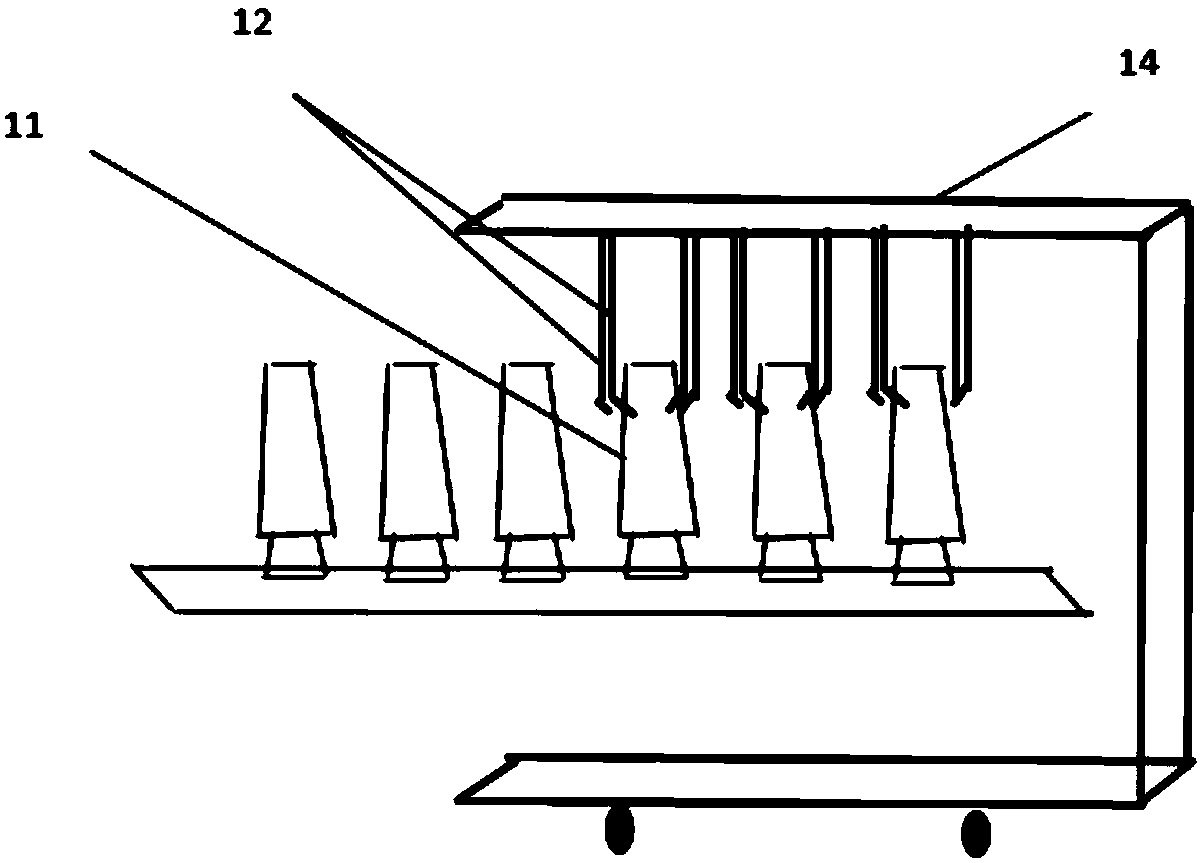

[0047] This embodiment provides a device for determining the spindle position information corresponding to the bobbin, see image 3 , the device includes:

[0048] At least two bobbin readers and movable supports;

[0049] The bobbin reader / writer is used to read and write the electronic label on the bobbin;

[0050] At least two bobbin reader-writers among the at least two bobbin reader-writers simultaneously read and write the electronic tags on the same bobbin.

[0051] When the device includes at least three bobbin reader-writers, the one-word arrangement includes a one-word cross arrangement.

[0052] The at least two bobbin readers are installed on a movable support;

[0053] Such as image 3 As shown, the present embodiment includes 6 bobbin reader-writers 12, and the positional relationship between the 6 bobbin reader-writers 12 and the bobbins 11 is as follows: Figure 4 In the third type of one-word cross arrangement, the bobbin reader is installed on the movabl...

Embodiment 3

[0060] This embodiment provides a system and method for automatically recording the spindle position information corresponding to the bobbin in multiple directions, see Figure 5 , the system includes:

[0061] At least two bobbin readers, quality inspection devices and movable supports;

[0062] The bobbin reader / writer is used to read and write the electronic label on the bobbin;

[0063] At least two bobbin reader-writers among the at least two bobbin reader-writers simultaneously read and write the electronic tags on the same bobbin.

[0064] When the device includes at least three bobbin reader-writers, the one-word arrangement includes a one-word cross arrangement.

[0065] The at least two bobbin readers are installed on a movable support;

[0066] The quality detection device is used to acquire the quality information of the bobbin on the bobbin;

[0067] The quality detection device comprises a weight measuring device and / or a quality detection device;

[0068] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com