A system and method for automatically recording spindle position information corresponding to bobbins

A technology of position and cop is applied in the field of automatically recording the position information corresponding to the cop, which can solve problems such as waste of resources, achieve the effects of saving resources, high efficiency, and avoiding the phenomenon of missed reading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

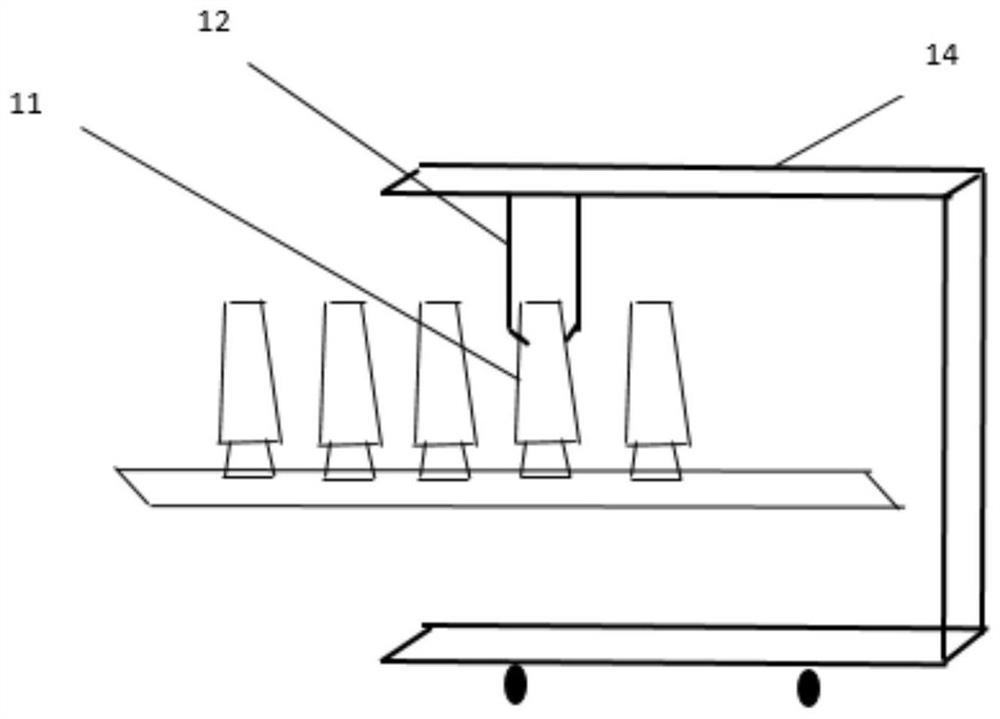

[0051] This embodiment provides a device for determining the spindle position information corresponding to the bobbin, see figure 1 , the device includes:

[0052] Bobbin 11, bobbin reader-writer 12 and movable support 14;

[0053] There is an electronic tag on the bobbin; the information in the electronic tag is used to determine the spindle position information corresponding to the bobbin; the bobbin reader is used to read the spindle in the electronic tag on the bobbin Bit information, the bobbin reader-writer is installed on the movable support.

[0054] The invention provides a device for determining the spindle position information corresponding to the yarn bobbin. The device includes: a bobbin, a bobbin reader-writer and a movable support; the bobbin has an electronic tag; the information in the electronic tag is used to determine the Corresponding spindle position information; the bobbin reader-writer is used to read or write the spindle position information in the e...

Embodiment 2

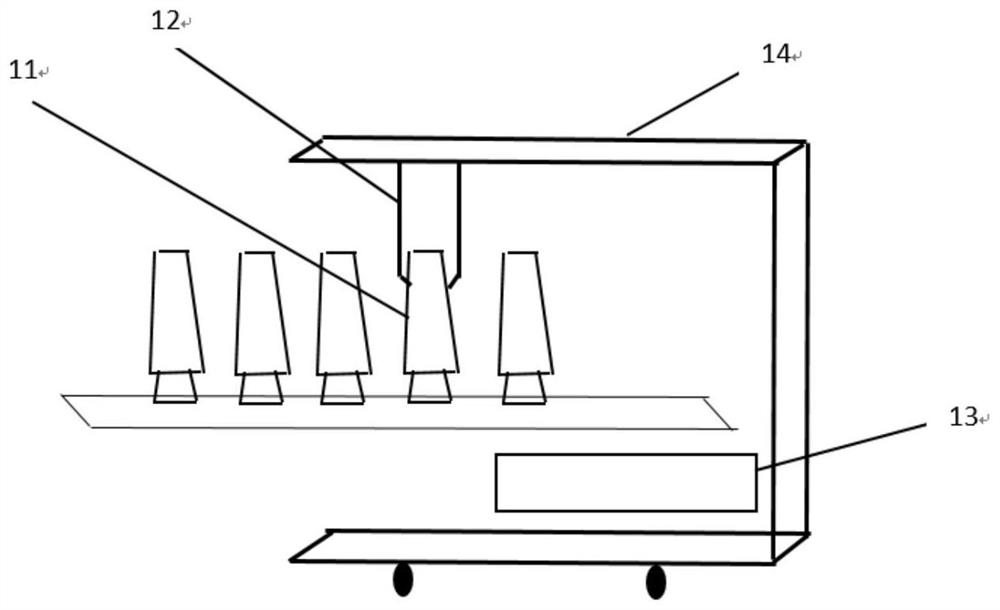

[0056] This embodiment provides a system and method for automatically recording the spindle position information corresponding to the bobbin, see figure 2 , the system includes:

[0057] Bobbin 11, bobbin reader-writer 12, bobbin quality detection device 13 and movable support 14;

[0058] There is an electronic tag on the bobbin; the information in the electronic tag is used to determine the spindle position information corresponding to the bobbin; the bobbin reader is used to read the spindle in the electronic tag on the bobbin Bit information, the bobbin reader-writer is installed on the movable support.

[0059] The method applied to the above-mentioned system for automatically recording the spindle position information corresponding to the bobbin includes:

[0060] Use bobbins with electronic labels in bobbin production equipment that needs to detect bobbin quality;

[0061] Moving the movable support to the bobbin production equipment that needs to detect the bobbin ...

Embodiment 3

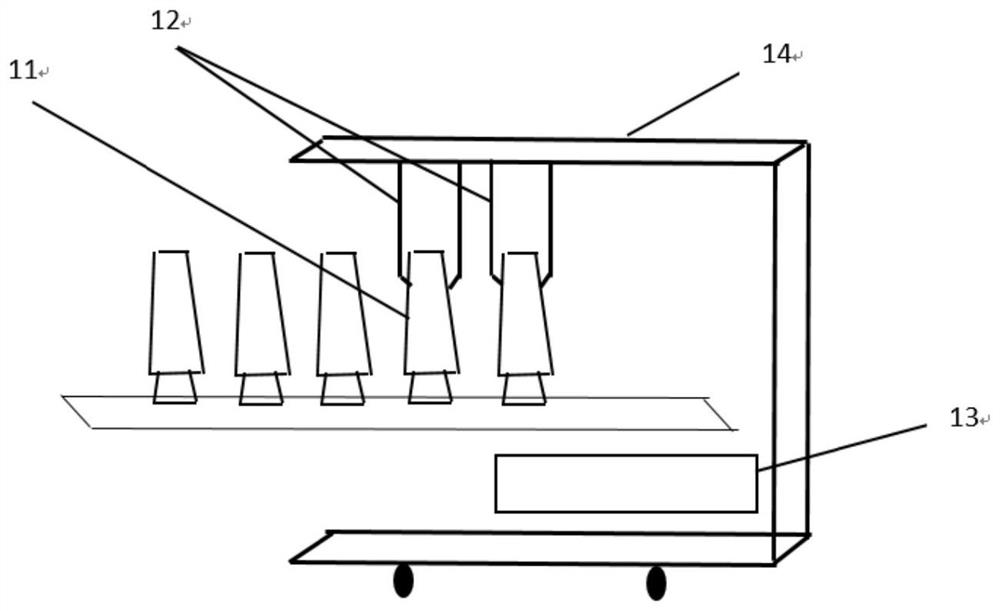

[0077] This embodiment provides a system and method for automatically recording the spindle position information corresponding to the bobbin, see image 3 , the system includes:

[0078] Bobbin 11, bobbin reader-writer 12, bobbin quality detection device 13 and movable support 14;

[0079] There is an electronic tag on the bobbin; the information in the electronic tag is used to determine the spindle position information corresponding to the bobbin; the bobbin reader / writer is used to read or write the electronic tag on the bobbin The spindle position information in the bobbin quality detection device is used to detect the bobbin quality of the bobbin bobbin, and the bobbin reader-writer is installed on the movable support.

[0080] The system includes at least two bobbin reader-writers, and the at least two bobbin reader-writers are arranged according to predetermined positions. The predetermined positions are arranged in a line; the at least two bobbin reader-writers are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com