Safety injection and containment spray mutual standby pipeline system of nuclear power station and verification method on basis of safety injection and containment spray mutual standby pipeline system

A verification method and technology for nuclear power plants, which are applied to the pipeline system of nuclear power plants where safety injection and injection safety and injection are mutually backup and the field of verification, can solve the problems of flow-induced vibration, high risk of operator exposure to radiation, and low reliability of the equipment itself. Enhance reliability, improve economic efficiency, and optimize the effect of debugging critical paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

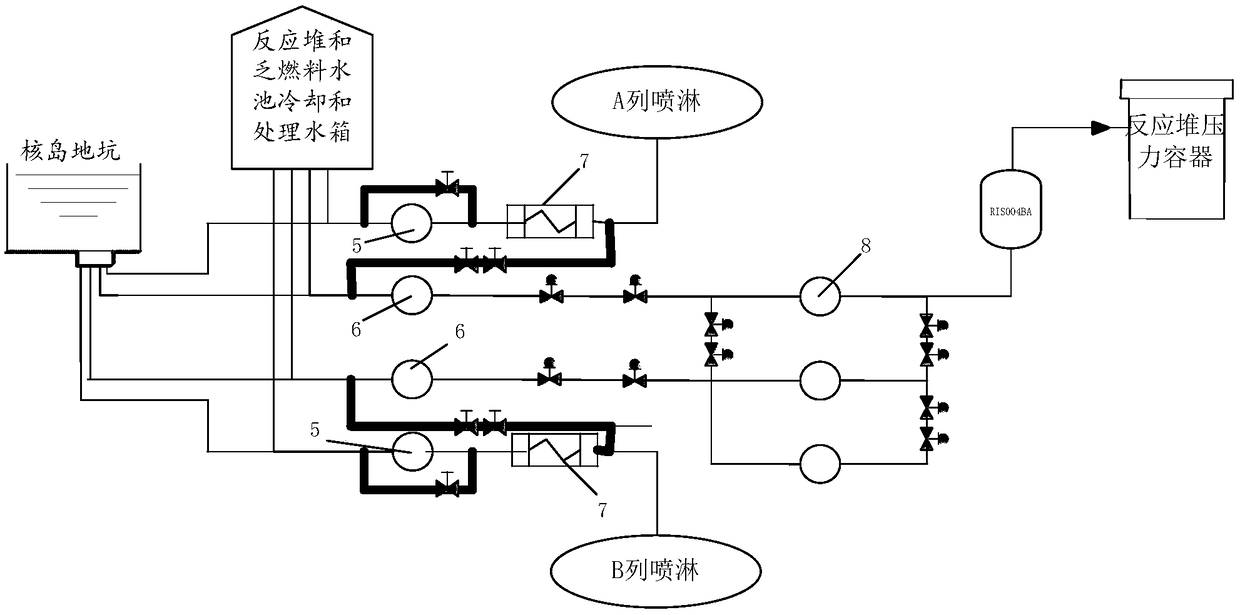

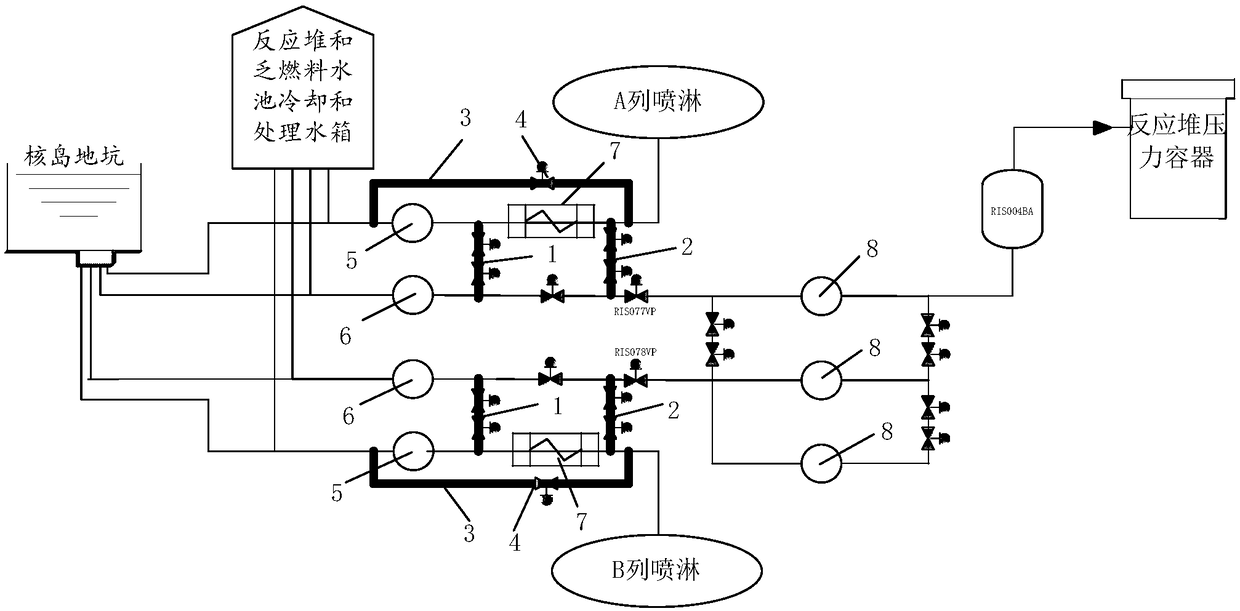

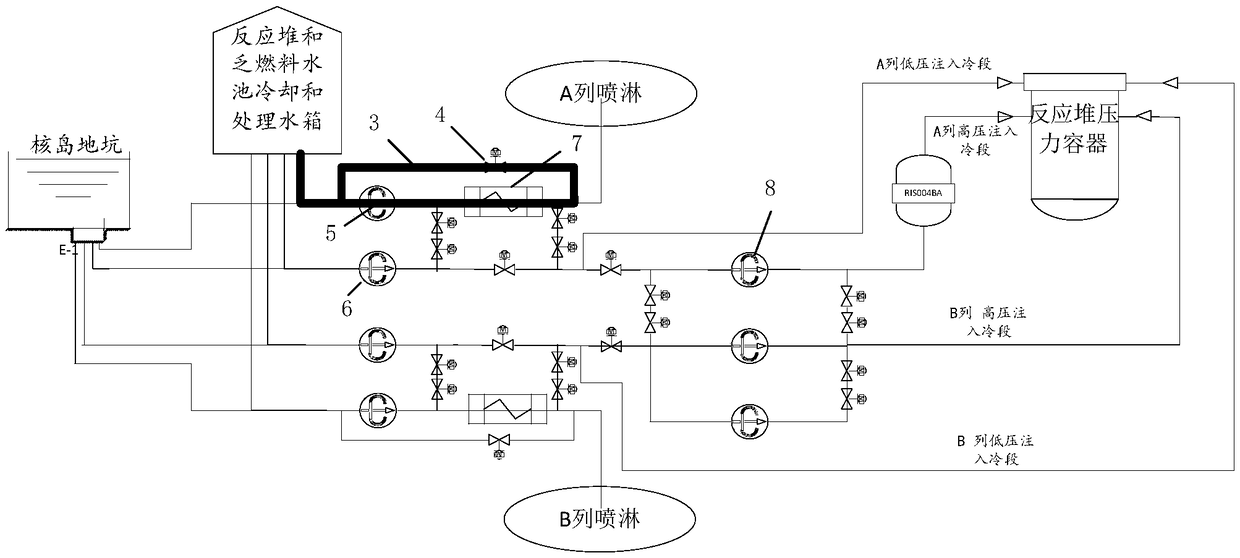

[0039] Such as figure 2 As shown, Embodiment 1 of the present invention provides a pipeline system in which safety injection and safety injection are mutually backup, including at least one set of H4 pipelines connected between the safety injection system and the containment spray system. In this embodiment, Including two sets of H4 pipelines respectively connected to the same safety injection system of columns A and B and the containment spraying system, so that the safety injection pumps and containment spraying pumps of columns A and B can be used during accident mitigation Each column of safety injection system includes nuclear island pit, low-pressure safety injection pump 6, high-pressure safety injection pump 8 and reactor pressure vessel which are sequentially connected by pipelines, and each column of safety spray system includes sequentially connected by pipelines Reactor and spent fuel pool cooling and processing water tank, containment spray pump 5 and containment...

Embodiment 2

[0042] Embodiment 2 of the present invention also provides a verification method, which uses multiple test conditions to verify that the safety injection and safety spray are mutually standby pipeline systems, and the multiple test conditions include: containment spray flow operating conditions, Containment spray pump standby low-pressure safety injection pump working condition, low-pressure safety injection pump standby containment spray pump spray working condition, two-row low-pressure safety injection pump using containment spray heat exchanger cold section injection working condition.

[0043] Specifically, the containment spray flow operating conditions include the containment spray flow operating conditions of columns A and B; the containment spray pump standby low-pressure safety injection pump operating conditions include the injection condition of the cold section, the increase One high-pressure safety injection pump cold section injection working condition of pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com