Horizontal adjustment mechanism of heating platform on full-automatic bonding equipment

A heating platform and level adjustment technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of time-consuming and labor-intensive adjustment of the heating platform, and achieve the effect of simple structure, practicality and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

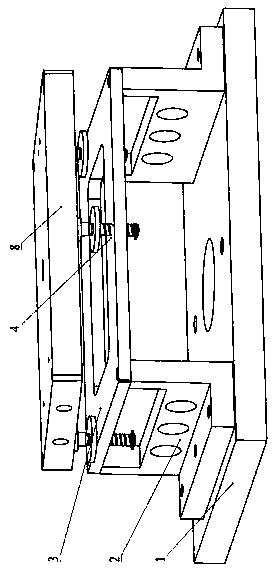

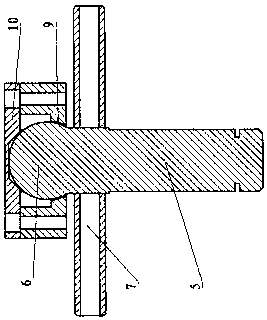

[0011] A horizontal adjustment mechanism for a heating platform on a fully automatic bonding equipment, comprising a bonding machine operating platform 1, a heating platform support frame 2 is fixedly arranged on the bonding machine operating platform 1, and a heating platform support frame 2 is fixedly arranged on the heating platform support frame 2 The workbench top plate 3 is provided with three threaded holes 4 on the workbench top plate 3, and the connecting lines of the three threaded holes 4 form a triangle, and a screw 5 is screwed in each threaded hole 4, and the three threaded holes 4 are screwed together. A heating platform 8 is provided at the top of the heating platform 8, a top connection groove 9 is provided on the bottom surface of the heating platform 8, a screw top connection ball head 6 is arranged on the top of the screw rod 5, and the screw top connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com