Industrial machining clamp

A fixture and industrial technology, applied in the field of industrial processing fixtures, can solve the problems of inability to meet special workpiece clamping requirements, poor guiding effect of bench vise, clamping position offset, etc., to improve the scope of application, avoid offset, meet Support the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

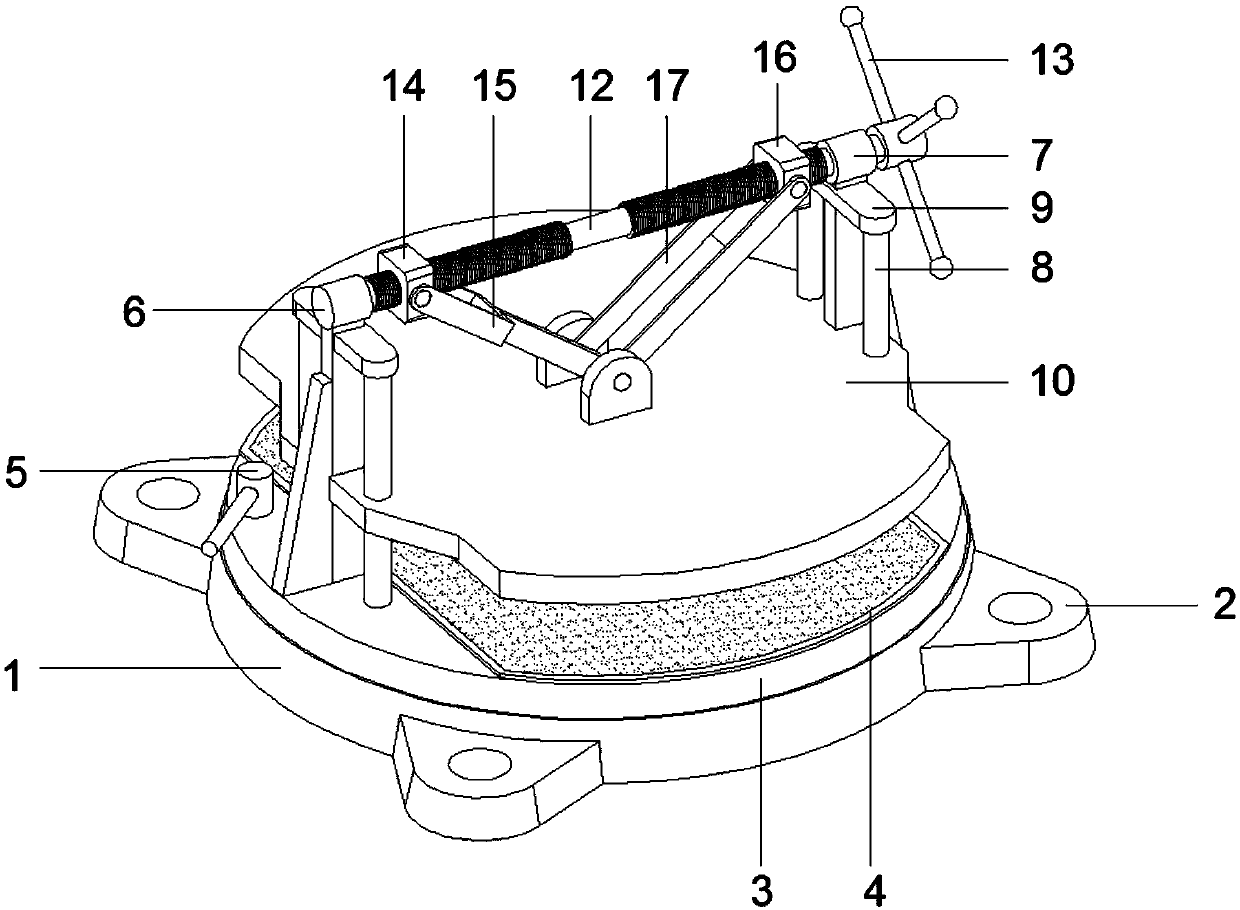

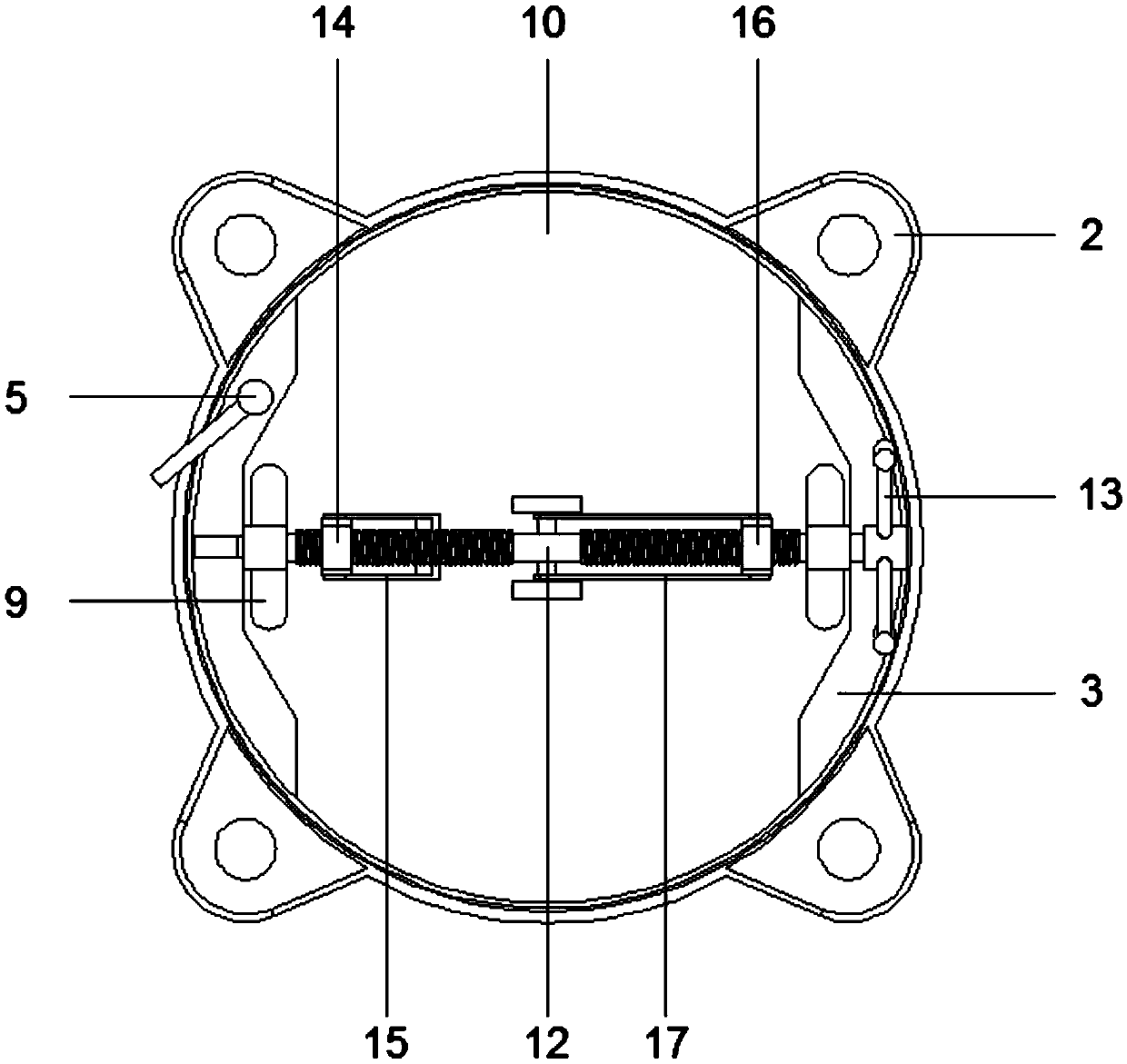

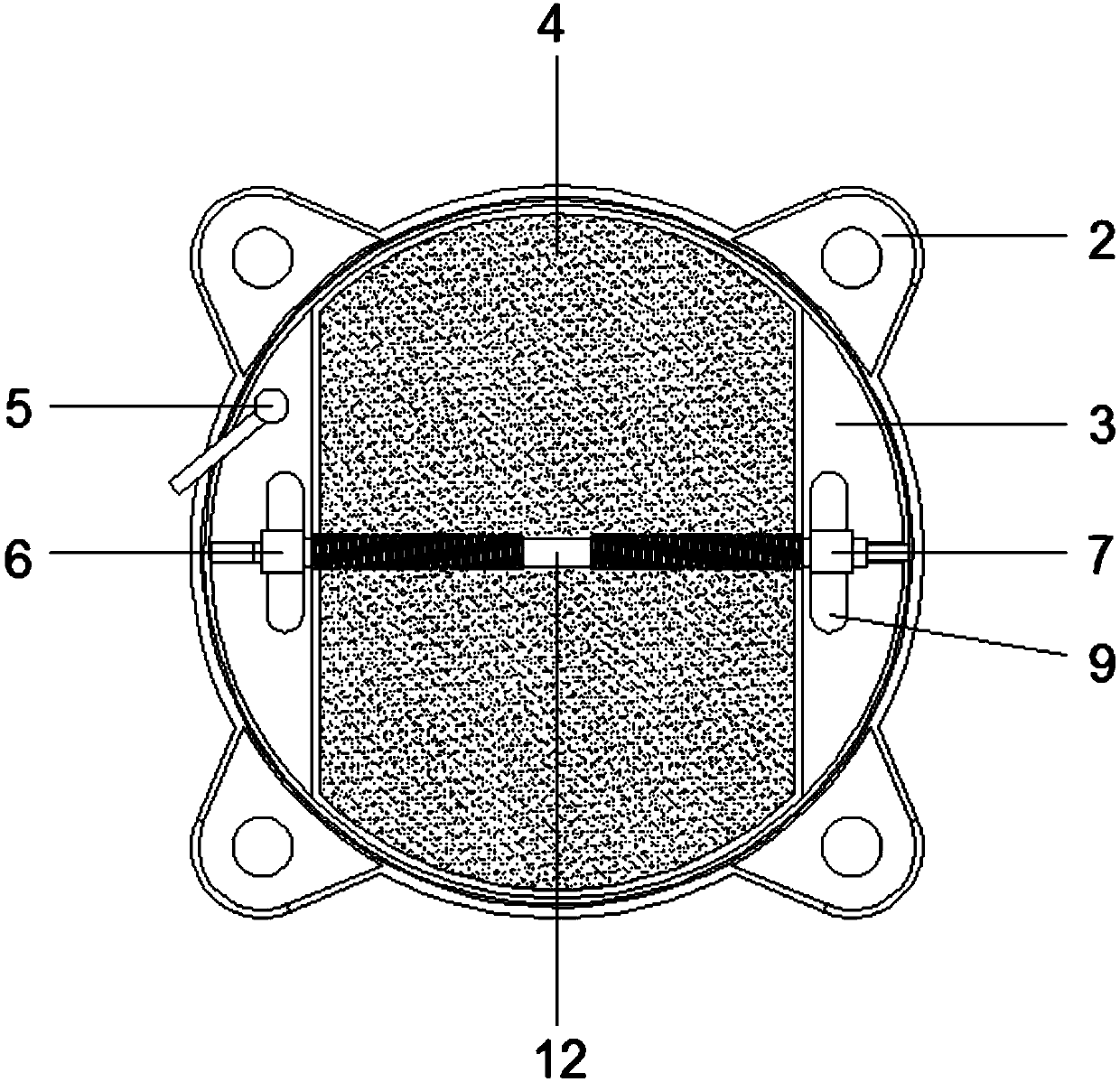

[0035]An industrial processing jig, the clamping area is large, the industrial processing jig has good guiding effect; it includes: chassis seat 1, mounting seat 2, base 3, fixed jaw 4, clamping handle 5, first support seat 6, second Two support bases 7, guide posts 8, guide post holders 9, splints 10, movable jaws 11, screw rods 12, rocking handles 13, first slides 14, first connecting rods 15, second slides 16, second Connecting rod 17; mounting seat 2 is arranged on both sides of chassis base 1, and mounting base 2 and chassis base 1 are integrated structure; base 3 is installed above chassis base 1, and the bottom of base 3 is embedded in chassis base 1 The inner side of the clamping handle 5 is embedded on the base 3; the first support base 6 is welded on one side of the top of the base 3, and the second support base 7 is welded on the other side of the top of the base 3; one end of the screw 12 Embedded and installed on the inside of the first support base 6, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com