Sanitary bath equipment processing and fixing equipment

A fixed equipment and equipment technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of poor processing effect, low processing precision, and difficulty in meeting the high requirements of modern consumers, and achieve improved stability, simplified induction systems, The effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

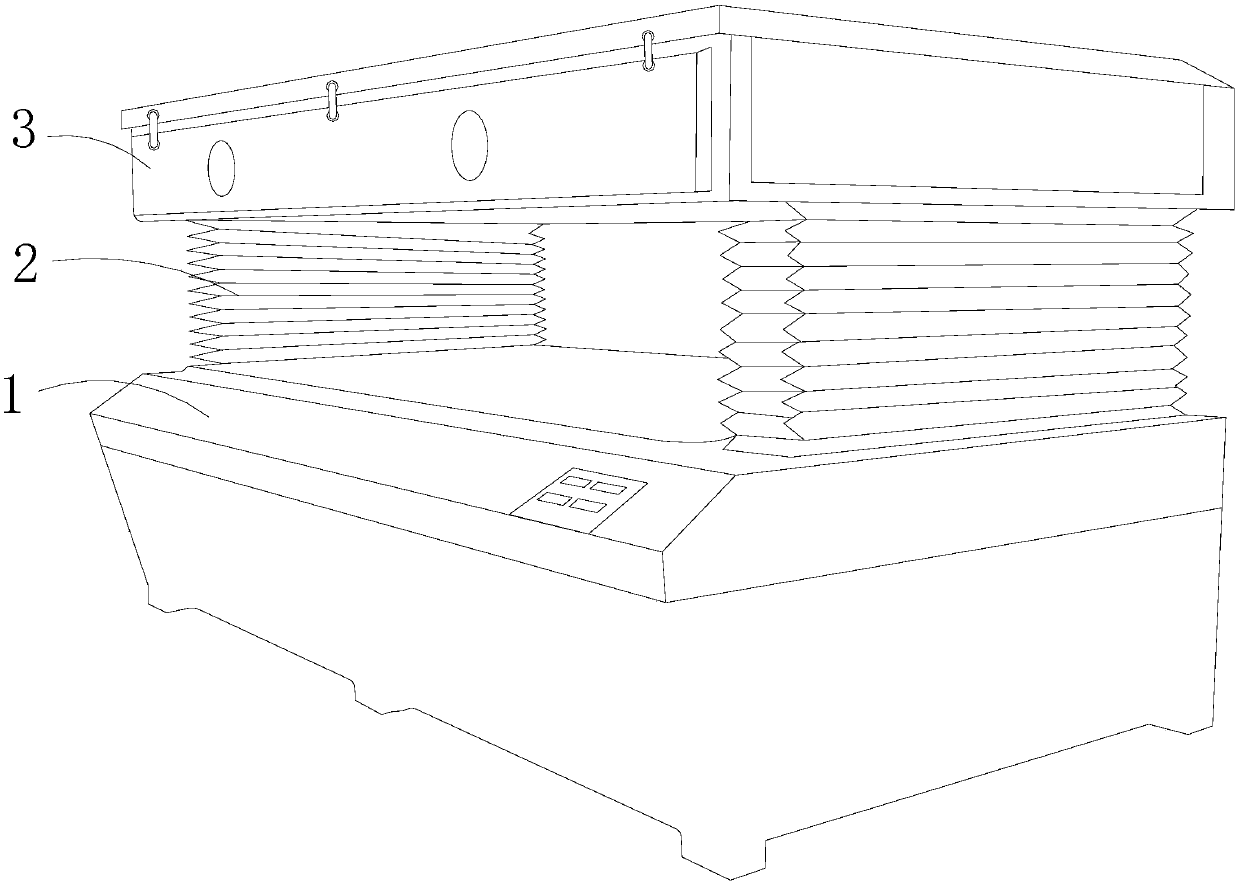

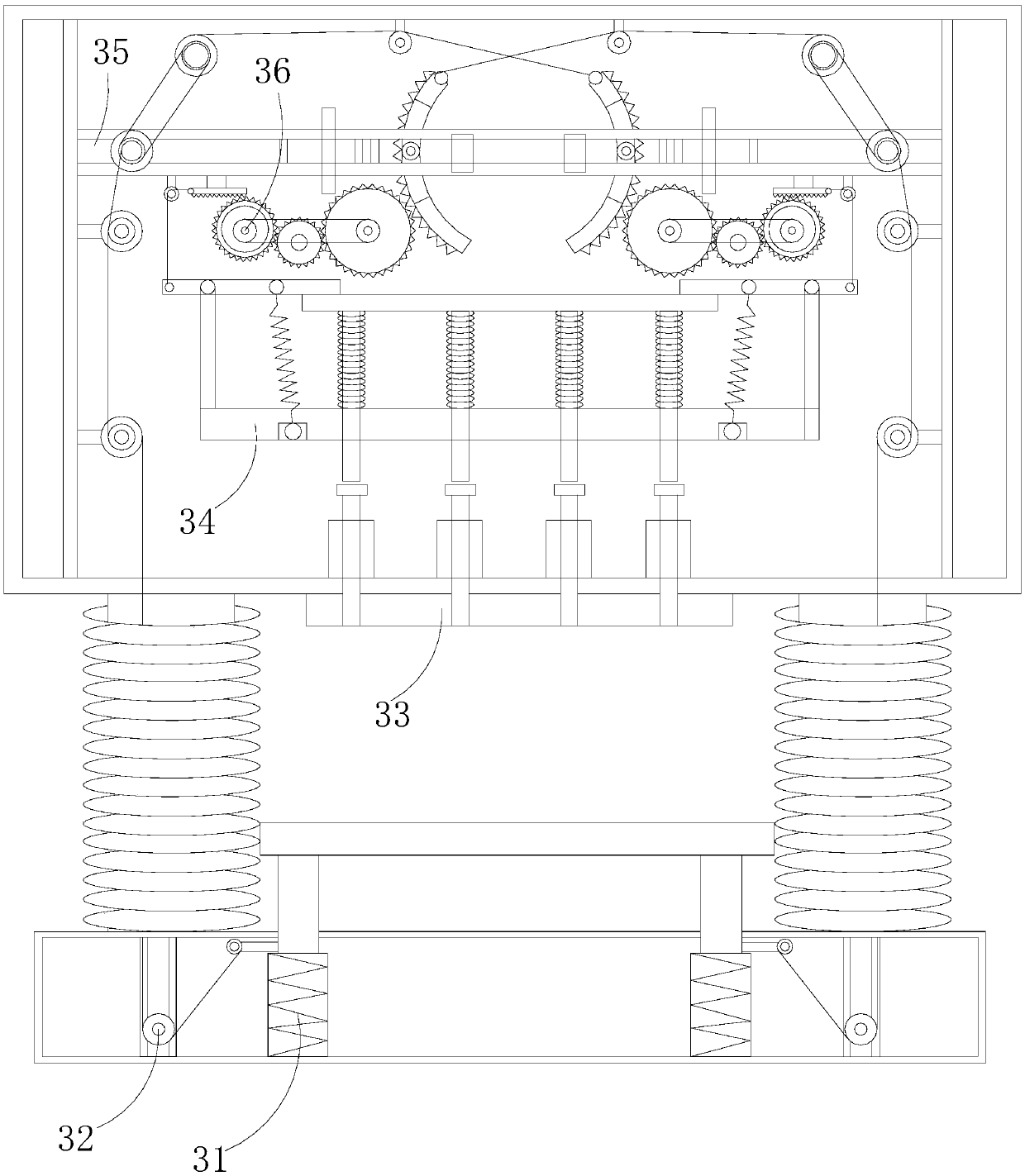

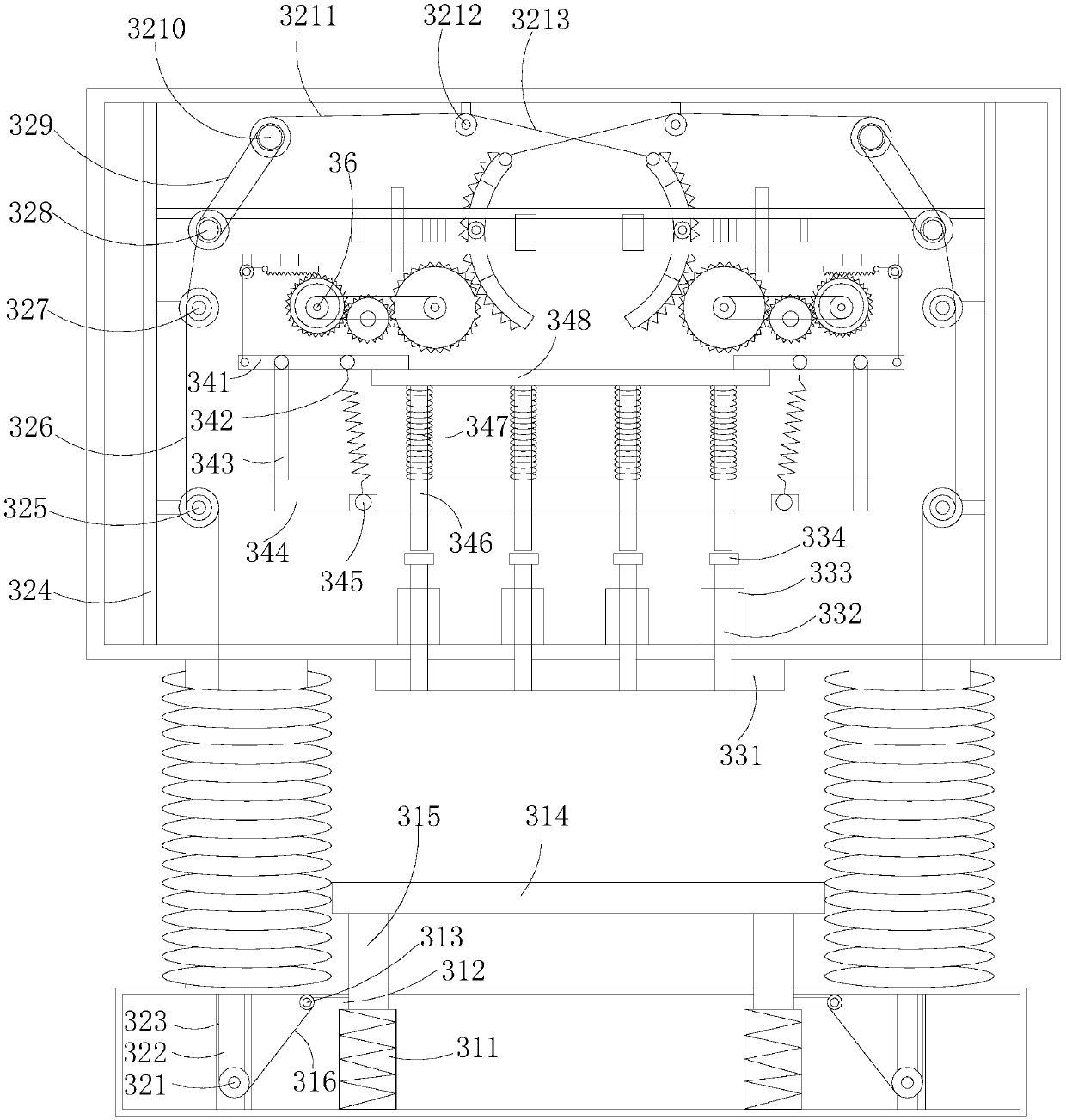

[0023] see Figure 1-Figure 5 , the present invention provides a bathroom equipment processing fixture, the structure of which includes a control host 1, a support column 2, and a control box 3. The control panel 1 is provided with a control panel for controlling the internal electrical execution system, and the control box 3 passes through The left and right ends of the bottom are welded into an integrated support column 2 and the control host 1 is vertically fixed into an I-shaped structure. The inside of the control box 3 is equipped with a fixed platform 31, a traction transmission mechanism 32, a compression mechanism 33, and a lever compression mechanism. 34. Linkage mechanism 35, horizontal transmission mechanism 36, the fixed platform 31 is set on the position where the control panel is arranged on the upper part of the control host 1 and is installed between the support columns 2, and one end of the traction transmission mechanism 32 is mechanically connected to Fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com