Clamp for sticking balance weight to surface of hub

A technology of hub surface and balance weight, which is applied in the direction of balancing rotating bodies, wheels, rims, etc., and can solve the problems of shape limitation, poor overall applicability, and insufficient arrangement of weight blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

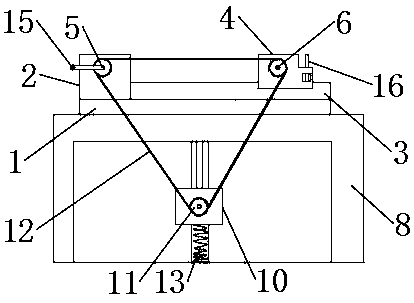

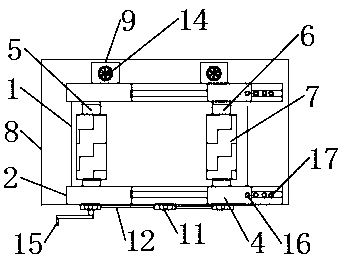

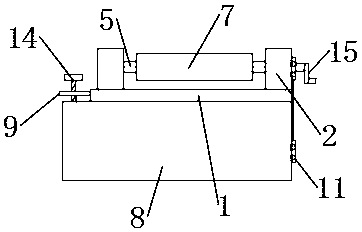

[0016] refer to Figure 1-3 , the present invention provides a technical solution: a fixture for mounting a balance weight on the surface of a wheel hub, including a base 1, a fixing plate 2 is welded on one side of the upper end of the base 1, and a sliding plate docked with the fixing plate 2 is connected to the other side of the base 1 through bolts. Rail 3, slide rail 3 is slidably connected with slider 4, fixed plate 2 and slider 4

[0017] The first roller shaft 5 and the second roller shaft 6 of the same type are respectively connected by bearings, and the slider 4 is matched with the second roller shaft 6 to adjust the distance between the first roller shaft 5 and the second roller shaft 6 for adapting to For hubs with different diameters, the first roller shaft 5 and the second roller shaft 6 are sleeved with rubber sleeves 7 of the same specification. The rubber sleeves 7 are used to protect the hub surface and prevent the hub surface from being scratched by burrs on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com