Anti-deformation lateral core pulling injection mold

A lateral core-pulling and injection mold technology, applied in the field of injection molds, can solve the problems of slow cooling speed, prolonging the time required for injection molding, material cracking, etc., to shorten the time required for cooling, improve the cooling molding efficiency, and speed up the speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

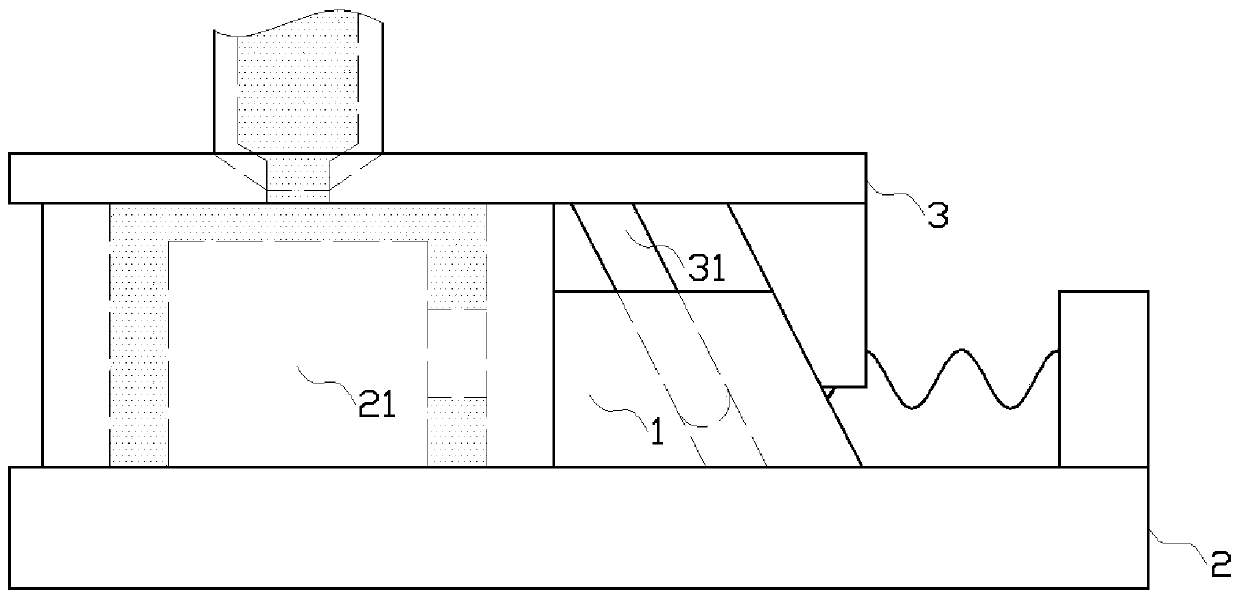

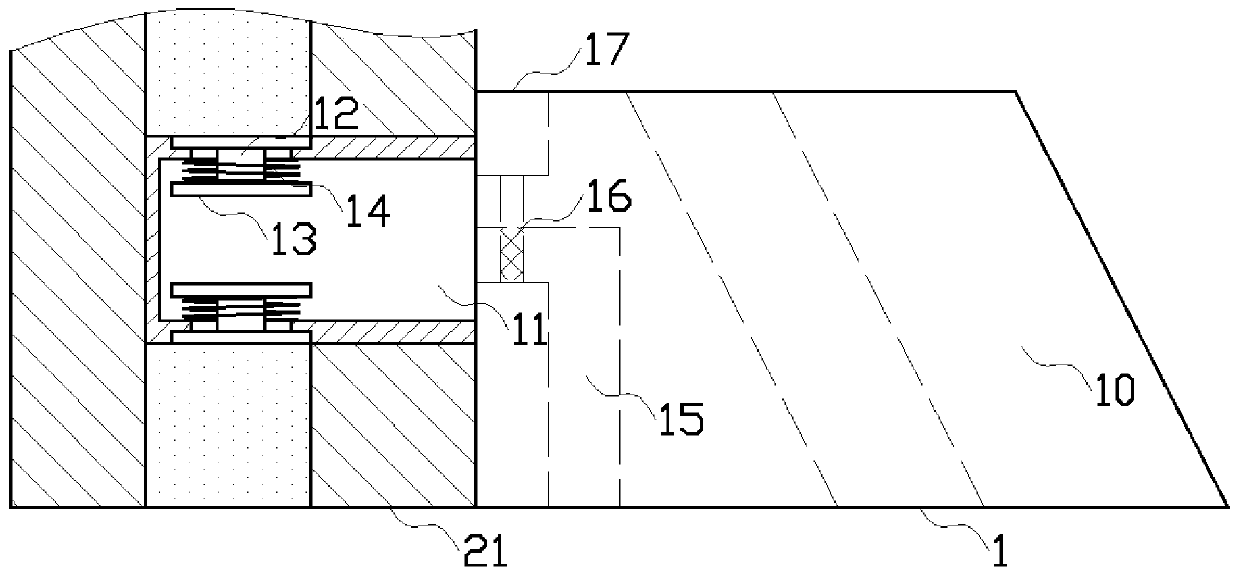

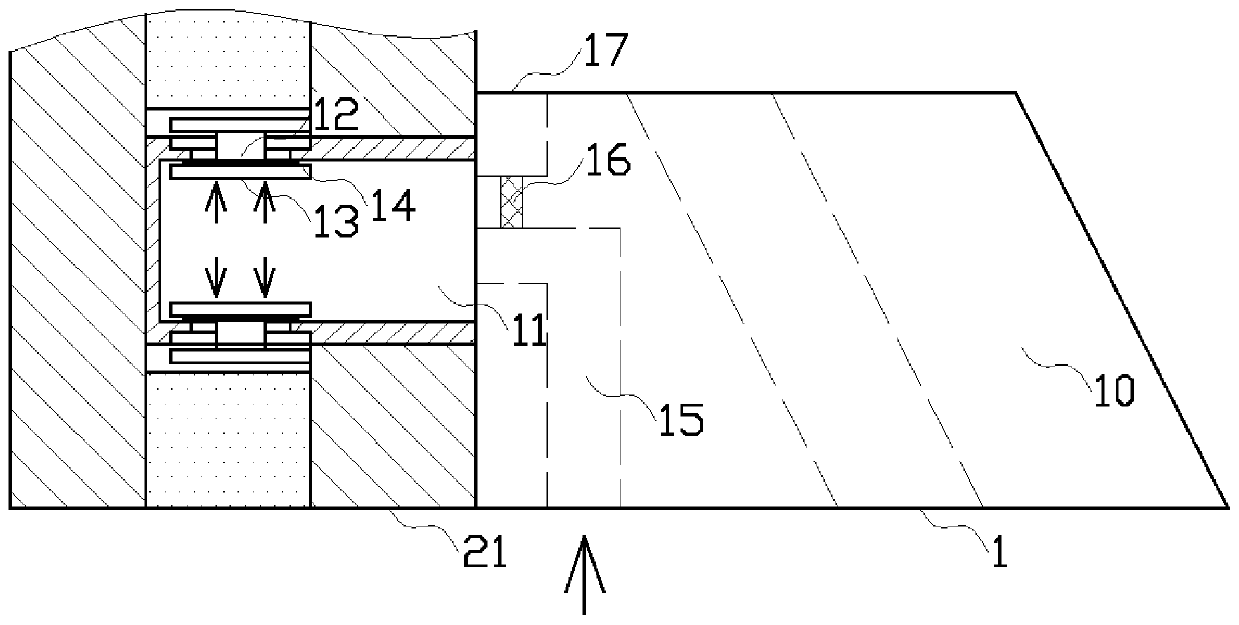

[0014] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the anti-deformation lateral core-pulling injection mold is a kind of injection mold that can compensate the shrinkage of the injection molded part to avoid cracking due to internal stress; in addition, it can be separated from the injection molded part during demoulding, avoiding the side The device for the phenomenon of friction damage between the core and the injection molded part includes a side core-pulling module 1; the side core-pulling module 1 is slidably assembled on the fixed mold module 2, and one side of the side core-pulling module 1 is provided with a The matching reset device, the other side is provided with a cavity 21 fixedly installed on the fixed mold module 2, and the cavity 21 is provided with a side core-pulling hole; the fixed mold module 2 is provided directly abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com