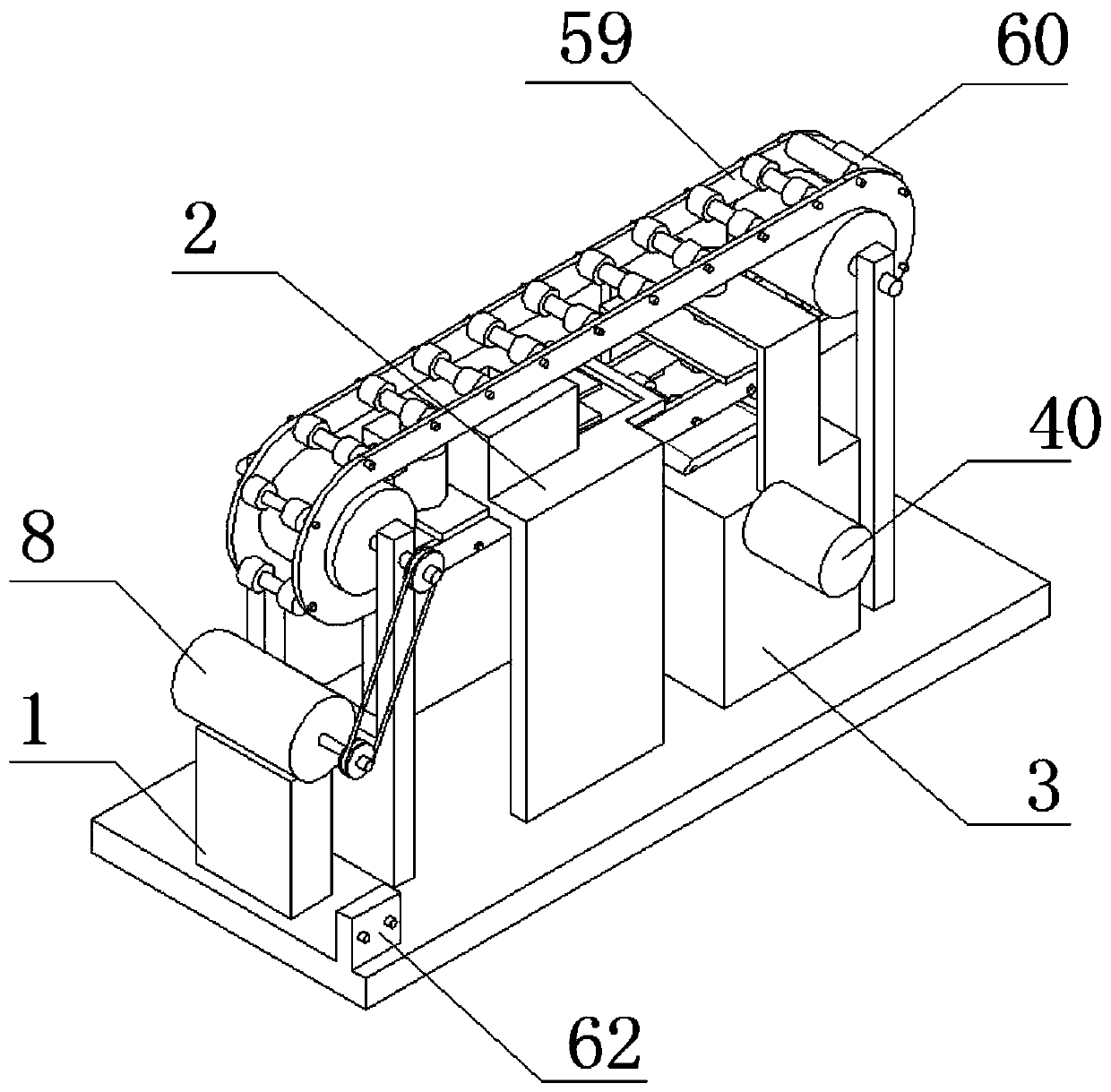

Ultrasonic full-automatic circular bottle labeling machine

A fully automatic, labeling machine technology, applied in the direction of labeling machines, labeling, labeling, etc., can solve the problems of increased production investment, noise, loss, etc., to improve the degree of uniform application, optimize the structure of mechanical glue application, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

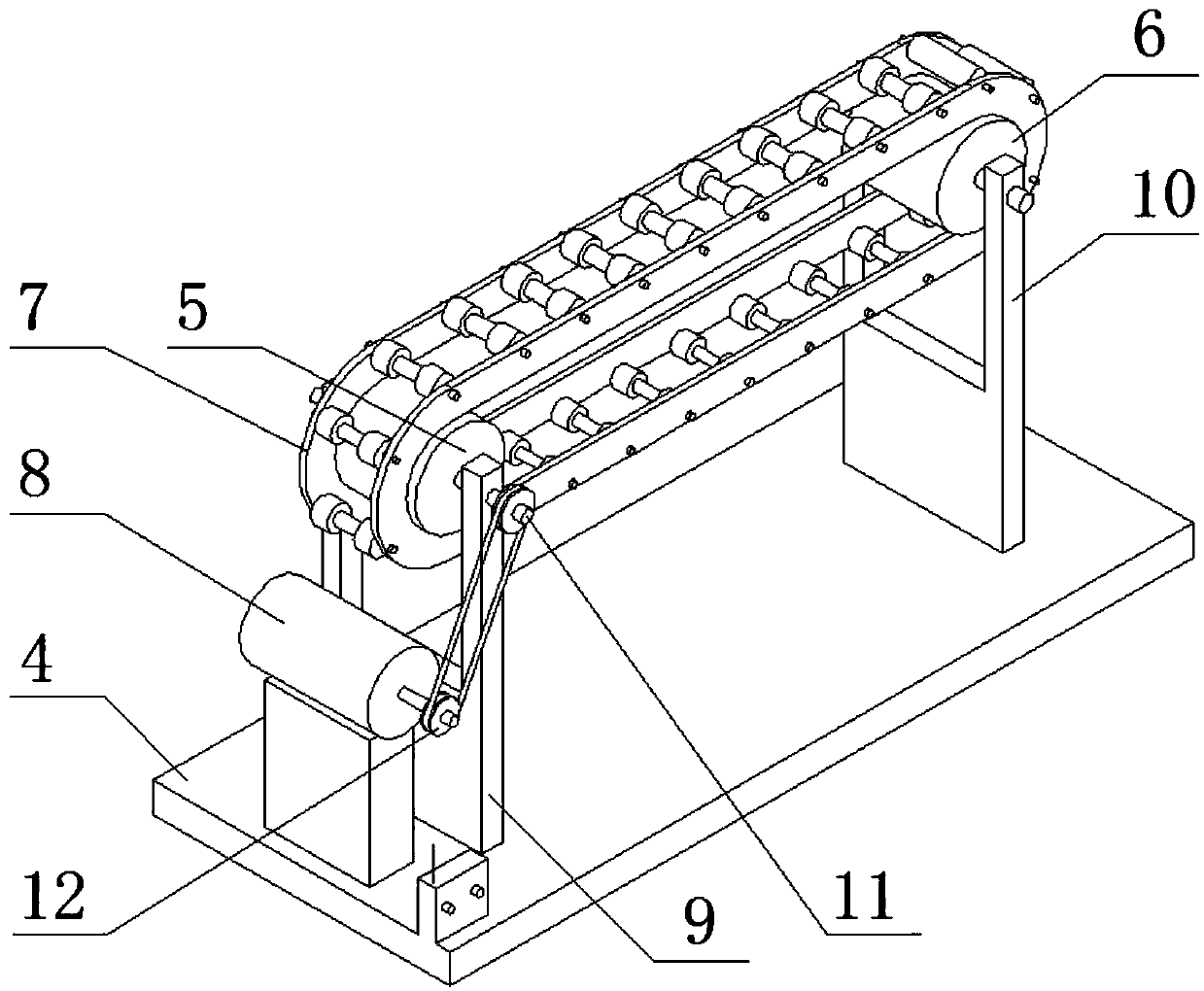

Method used

Image

Examples

Embodiment approach

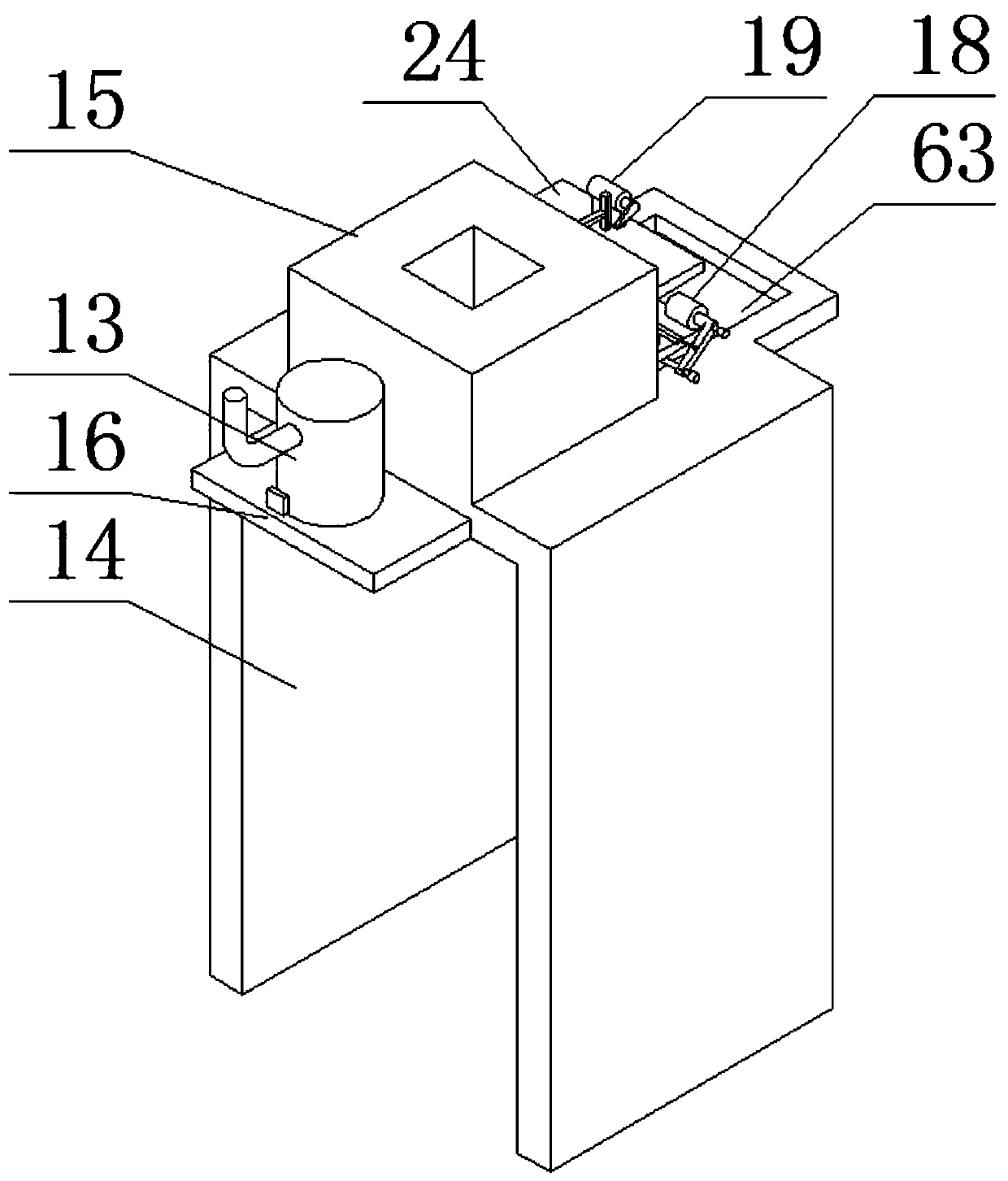

[0029] As a preferred embodiment of the present invention, the elastic spray valve 25 includes a spray sleeve 50, a spray valve rod 51 and a mist outlet spring 52, the spray valve rod 51 is sleeved in the spray sleeve 50, and the outlet The mist spring 52 is arranged between the spray sleeve 50 and the spray valve stem 51 , the spray valve stem 51 is provided with a mist outlet channel, and one side of the spray sleeve 50 is provided with a mist inlet pipe.

[0030] As a preferred embodiment of the present invention, the paper feeding mechanism 18 includes a paper feeding motor 53, a paper feeding connecting rod 54, a telescopic rod 55 and a paper feeding wheel 56, and one end of the paper feeding motor 53 passes through the paper feeding connecting rod. 54 is connected with the paper feeding connecting rod 54, and the paper feeding connecting rod 54 is connected with the paper feeding bracket 23 through the telescopic rod 55, and one end of the paper feeding wheel 56 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com