Internal Force Adjustment Method of Concrete Slab of New Steel Concrete Composite Beam

A technology of concrete slabs and adjustment methods, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of complex tensioning process and low efficiency of prestressed tendons, and achieve simple construction methods, safe structural stress, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] An embodiment of the present invention provides a method for adjusting the internal force of a new steel-concrete composite beam concrete slab, which includes the following steps:

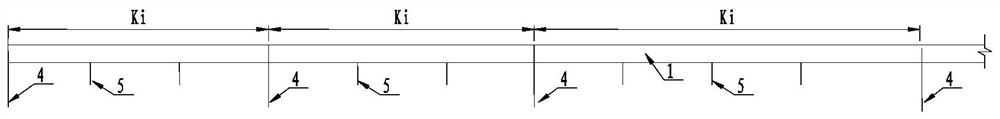

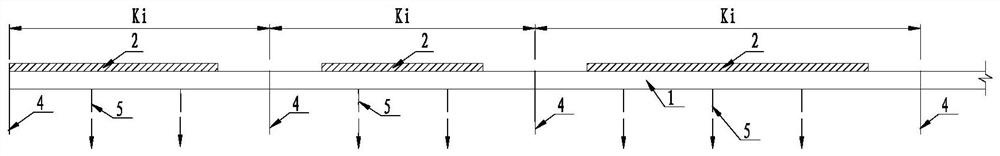

[0026] After the steel main girder 1, multiple formal fulcrums 4 of pier tops and multiple mid-span temporary fulcrums 5 are in place, multiple mid-span concrete slabs 2 are constructed on the steel main girder 1, and the gap between adjacent mid-span concrete slabs 2 There is a gap, which is located at the official fulcrum 4 of the pier top, and is used for the subsequent construction of the pier top concrete slab 3;

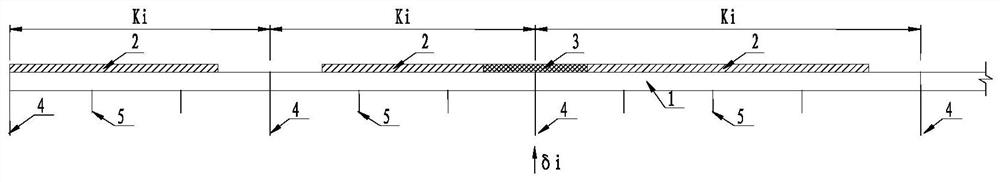

[0027] Sink the temporary fulcrum 5 in the middle of the span, then raise the formal fulcrum 4 of the pier top, construct the pier top concrete slab 3 in the gap between two adjacent mid-span concrete slabs 2, and then lower the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com