Method for installing isolation fence

An installation method and isolation barrier technology, which can be applied to road safety devices, construction material processing, roads, etc., can solve the problems of unreliable installation and unsmooth installation line, and achieve the effect of firm installation, labor cost saving, and overall smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

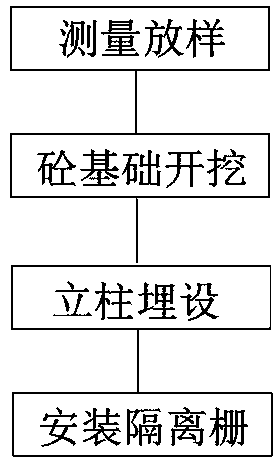

[0020] Embodiment one, combined with the attached figure 1 And attached figure 2 , a method for installing an isolation barrier, comprising a column 1 and an isolation barrier 2, is characterized in that it includes the following steps:

[0021] a. Measurement and stakeout, survey and measure the construction site, set the ground repair in a ladder shape, stake out and mark, after locating the position of column 1 in the center, determine other column positions according to the column distance, and mark them with wooden stakes;

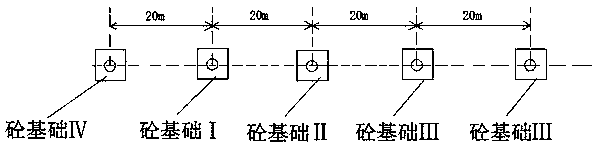

[0022] b. For the excavation of concrete foundation, set up concrete foundation II at the corner of the straight line, set up concrete foundation IV at the end of the straight line, set up concrete foundation I, concrete foundation II, and concrete foundation III every 20m on the straight line, Concrete foundation IV: Excavate the foundation pit, tamp the foundation, and check the axis and spacing on the same straight line;

[0023] c. For column e...

Embodiment 2

[0029] Embodiment two, according to the attached figure 1 , the material of the isolation grid 2 is set as low-carbon steel wire of φ3.5mm, the isolation grid 2 is made of steel plate and iron wire, the central sag after the iron wire is tightened and fixed is less than 15mm, and each column 1 The bending degree shall not exceed 8mm / m. Galvanized and plastic-coated anti-corrosion materials are respectively provided on the outer wall of the isolation grid 2 from the inside to the outside. Polyethylene or polyester, the material of the plastic layer of the isolation grid 2 is polyethylene, and the thickness of the plastic layer is 0.3mm. The material of the plastic layer of the isolation grid 2 is polyester, and the thickness of the plastic layer is 0.1mm. The columns 1 are all cast-in-place with C26 concrete.

[0030] The isolation fence 2 made of steel plate and iron wire should be flat after installation, without obvious warping and unevenness. Deformation, curling or scrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com