Anti-settlement intelligent pipeline system

An intelligent pipeline and anti-settling technology, applied in sewer pipeline systems, waterway systems, water supply devices, etc., can solve problems such as low efficiency, long time consumption, and rigid interface breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

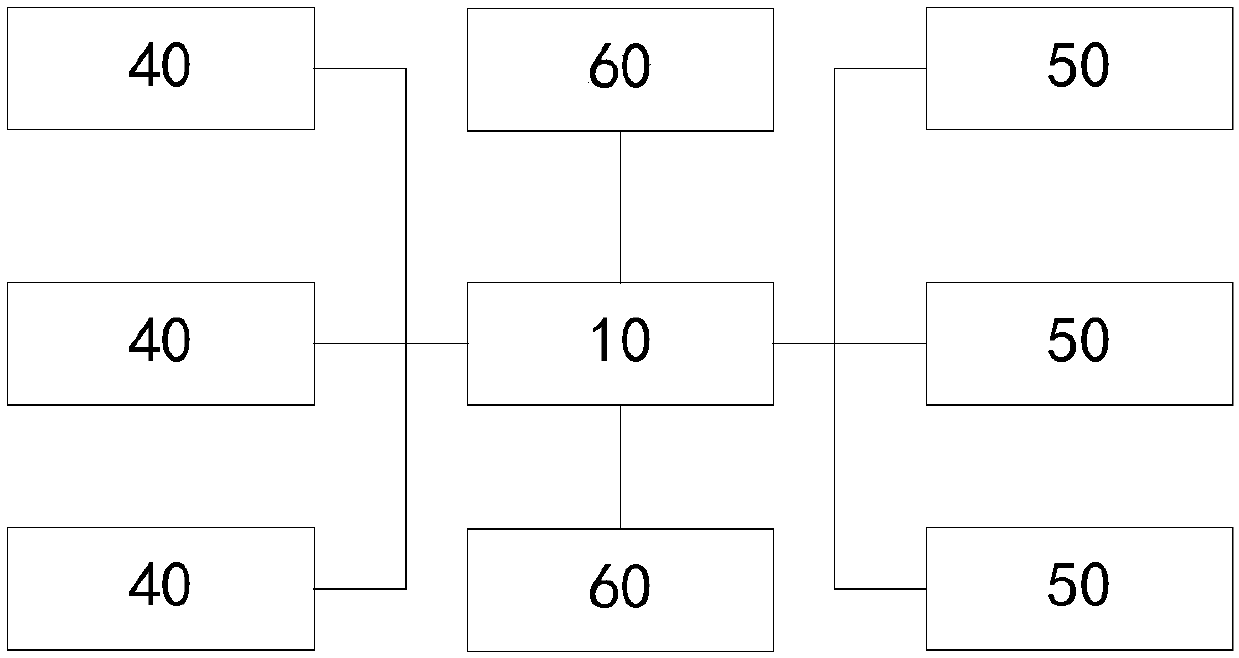

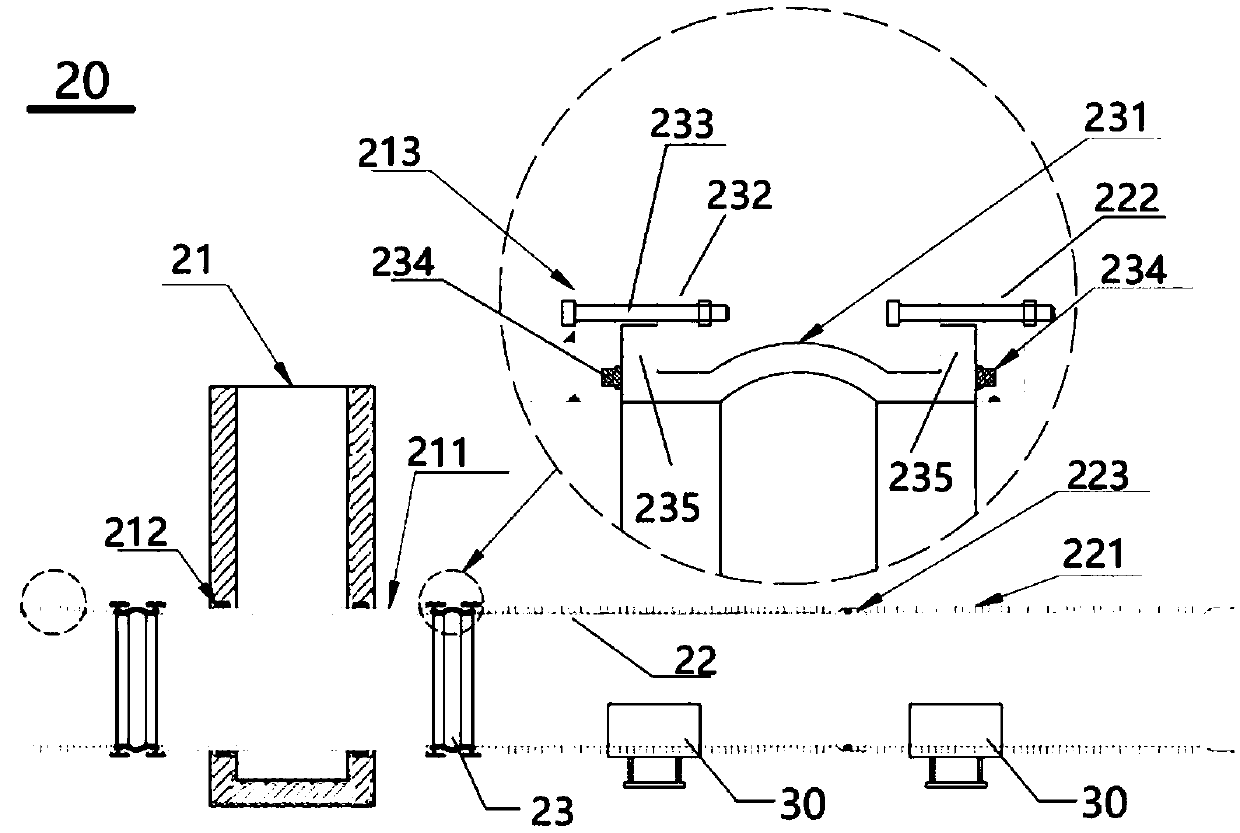

[0072] see figure 1 , the present invention discloses an anti-subsidence intelligent pipeline system, comprising a pipeline device 20, at least one pipeline support 30, several monitoring terminals 40 arranged in the pipeline device, at least one displacement compensation device 50, and a server 10, and the servers 10 are respectively Each monitoring terminal 40 and each displacement compensation device 50 are connected. In addition, the intelligent monitoring system may also include several mobile terminals 60 , the server 10 is connected to each mobile terminal 60 , and the user can obtain the information of each monitoring terminal 40 from the server through the mobile terminal 60 .

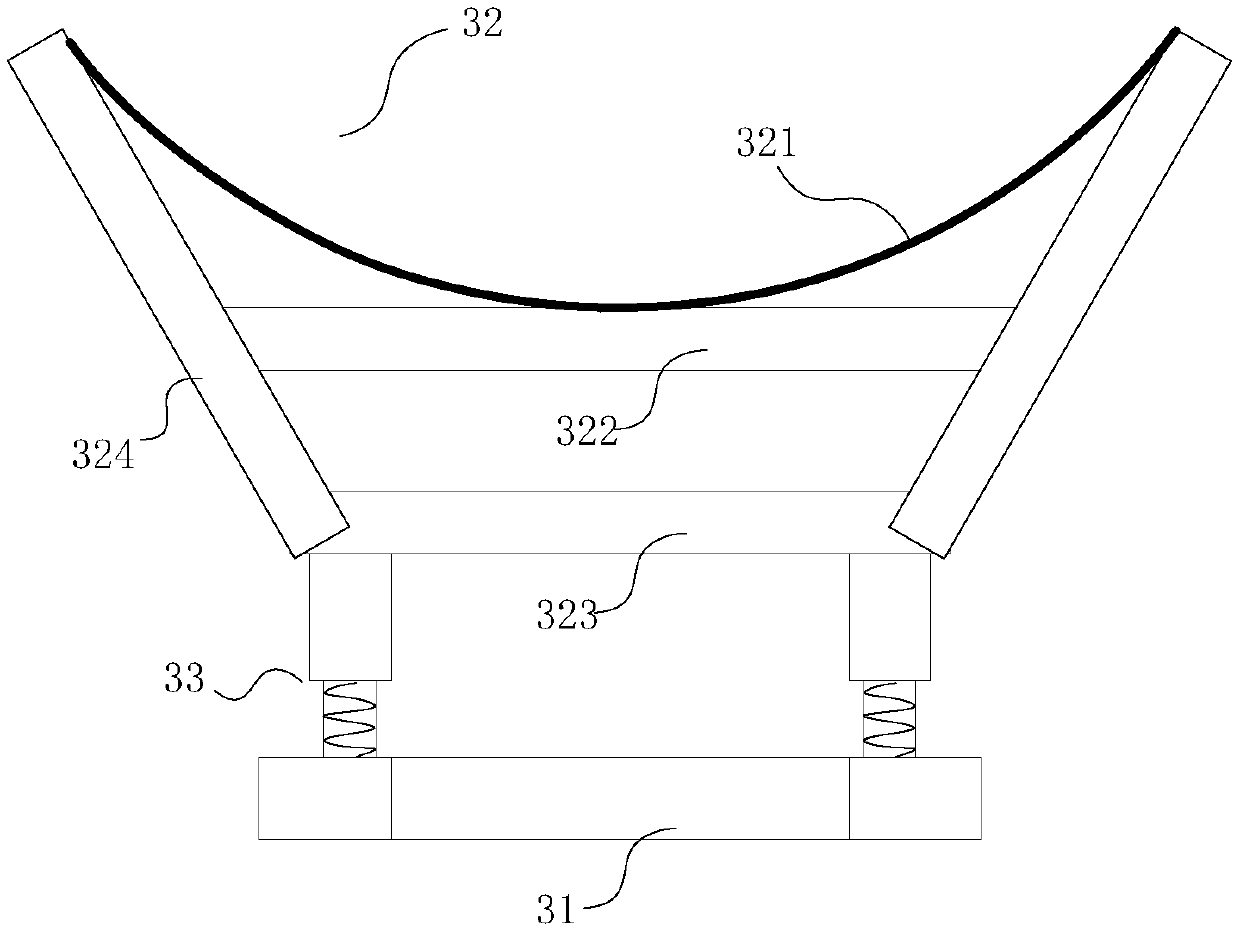

[0073] The pipeline device 20 includes at least one inspection well and several drainage pipelines 22, and each inspection well is connected to the corresponding drainage pipeline 22; the pipeline support 30 is placed under the corresponding drainage pipeline 22 to support the corresponding dr...

Embodiment 2

[0093] The difference between this embodiment and Embodiment 1 is that please refer to Figure 9 , Figure 10 , in this embodiment, the displacement compensation device 50 includes a second displacement compensation mechanism 52 . Of course, the second displacement compensation mechanism 52 can also be regarded as a specific implementation of the first displacement compensation mechanism 51 .

[0094] The second displacement compensation mechanism 52 includes a cylinder 521 , a piston 522 , a piston rod 523 , a switch pin 524 , and an electric actuator 525 . A part of the piston rod 523 and the piston 522 are arranged in the cylinder 521 .

[0095] The cylinder 521 is divided into three areas, namely the first area 5211, the second area 5212, and the third area 5213. The piston 522 is arranged between the first area 5211 and the second area 5212. The first area 5211 Set above the second area 5212, the second area 5212 stores high-pressure gas; the third area 5213 is respecti...

Embodiment 3

[0099] The difference between this embodiment and Embodiments 1 and 2 is that please refer to Figure 8 , in this embodiment, the displacement compensating device 50 further includes a pad increasing and decreasing robot 53 and several pads 54 . The gasket increasing and decreasing robot 53 can increase the gasket 54 to the top of the supporting member 34 when the telescopic mechanism 512 is extended so that the drainage pipeline 22 is lifted away from the supporting member 34 to increase the supporting member 34 The support height of the drainage pipeline 22, or when the telescopic mechanism 512 is extended so that the drainage pipeline 22 is lifted away from the support component 34, the gasket 34 can be removed from above the support member 34 to lower the The support height of the support member 34 to the drainage pipeline 22 .

[0100] The shim adding and removing robot 53 includes a robot control circuit 531, a robot gripper 532, a robot driving mechanism 533, and a sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com